Patents

Literature

54 results about "Dimethyl p-phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil performance improver, and preparation method and application thereof

InactiveCN110144247AImprove low temperature fluidityImprove solubilityLiquid carbonaceous fuelsFuel additivesSolubilityPolymer science

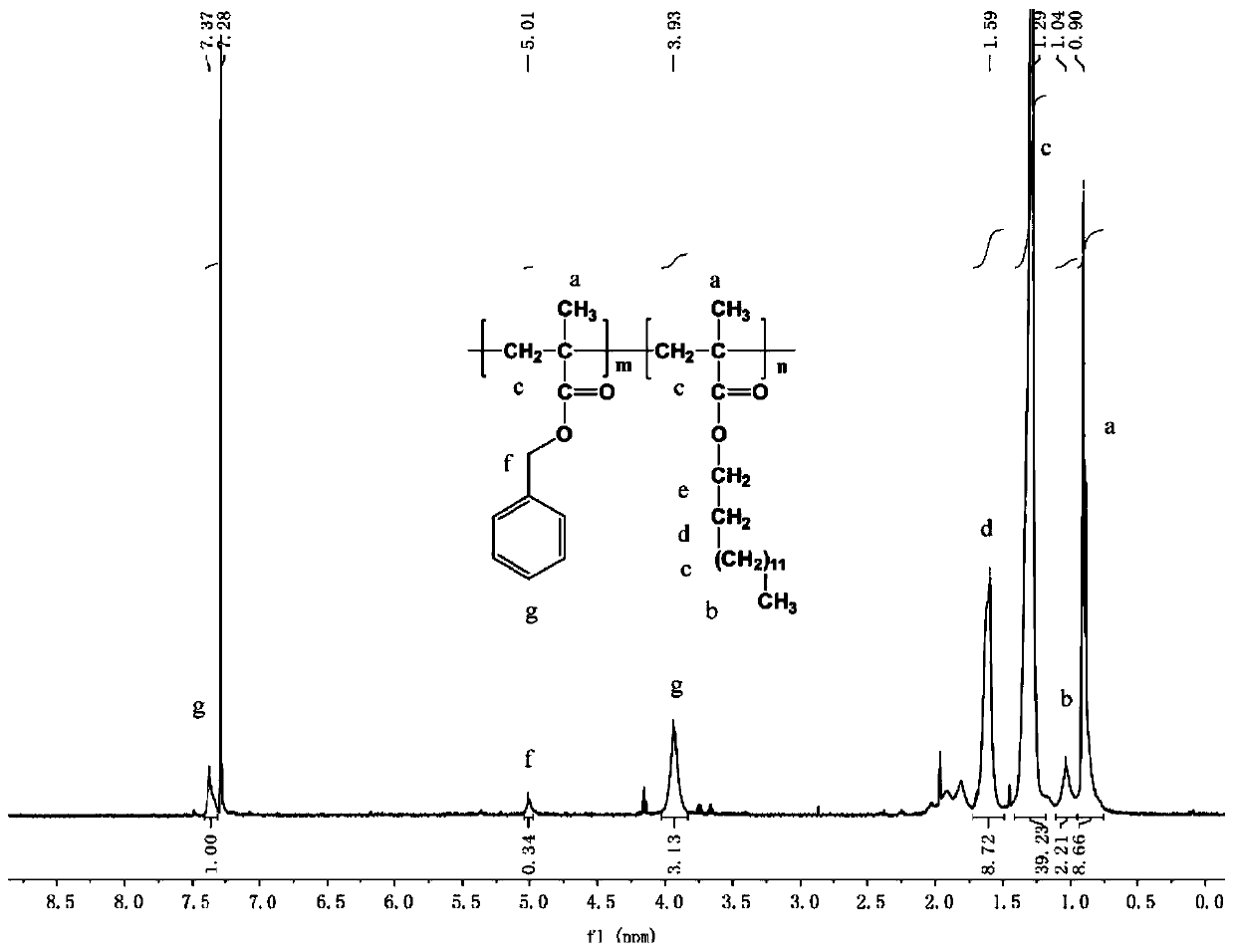

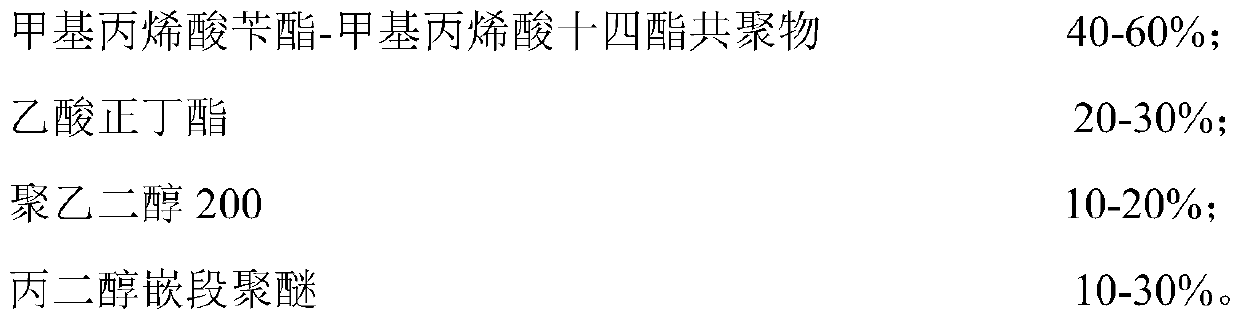

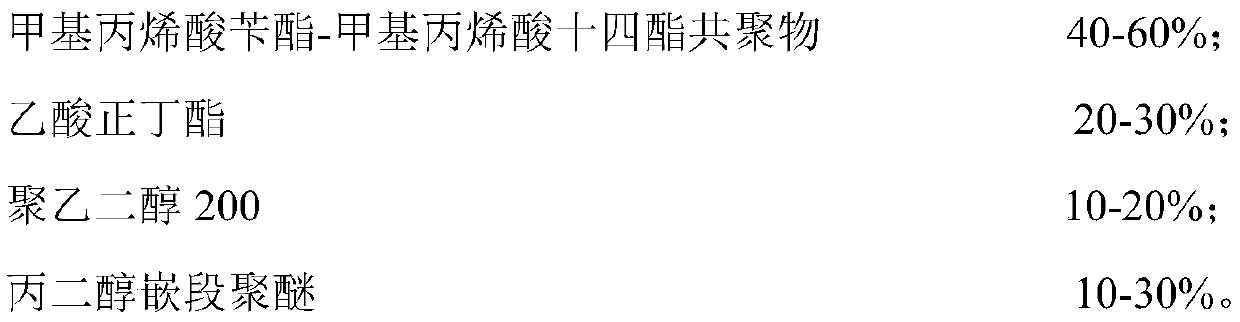

The invention provides an oil performance improver. The oil performance improver comprises, by mass, 40-60% of benzyl methacrylate-tetradecyl methacrylate and 25-70% of a solvent; and the solvent is composed of 20-40% of dimethyl phthalate and 5-20% of cyclohexane, or the solvent is composed of 10-30% of n-butyl acetate, 5-20% of polyethylene glycol 200 and 10-20% of propylene glycol block polyether. The above diesel pour point depressant composition of the invention can effectively enhance the solubility of a pour point depressant in diesel, reduce the cost of the pour point depressant and effectively improve the low-temperature flow performance of the diesel.

Owner:SHANGHAI INST OF TECH

Thermal regenerant for asphalt concrete pavement and preparation method thereof

InactiveCN101649067AAchieve in-situ recyclingEco-friendlyProductsReagentsRoad surfaceProcessing cost

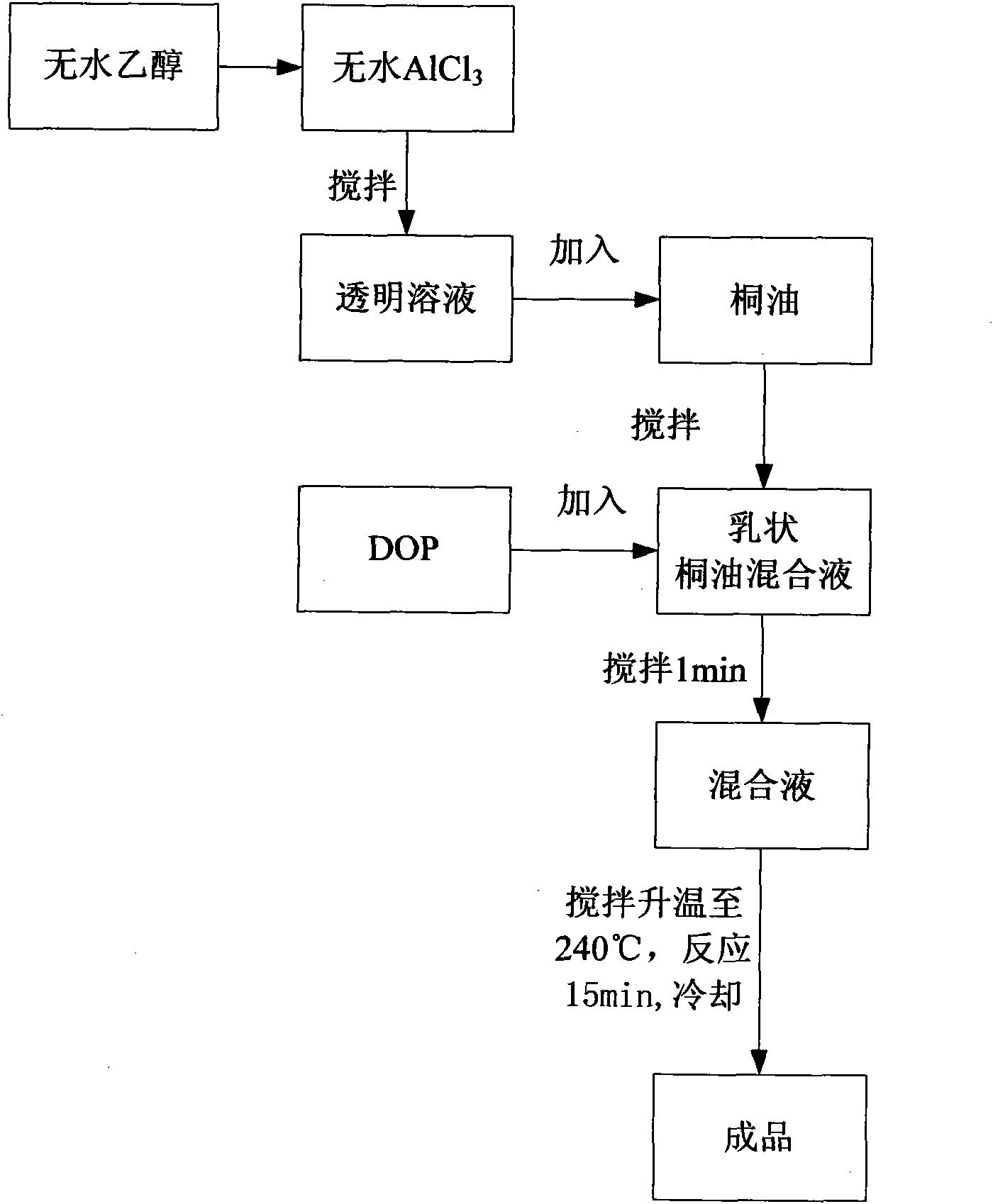

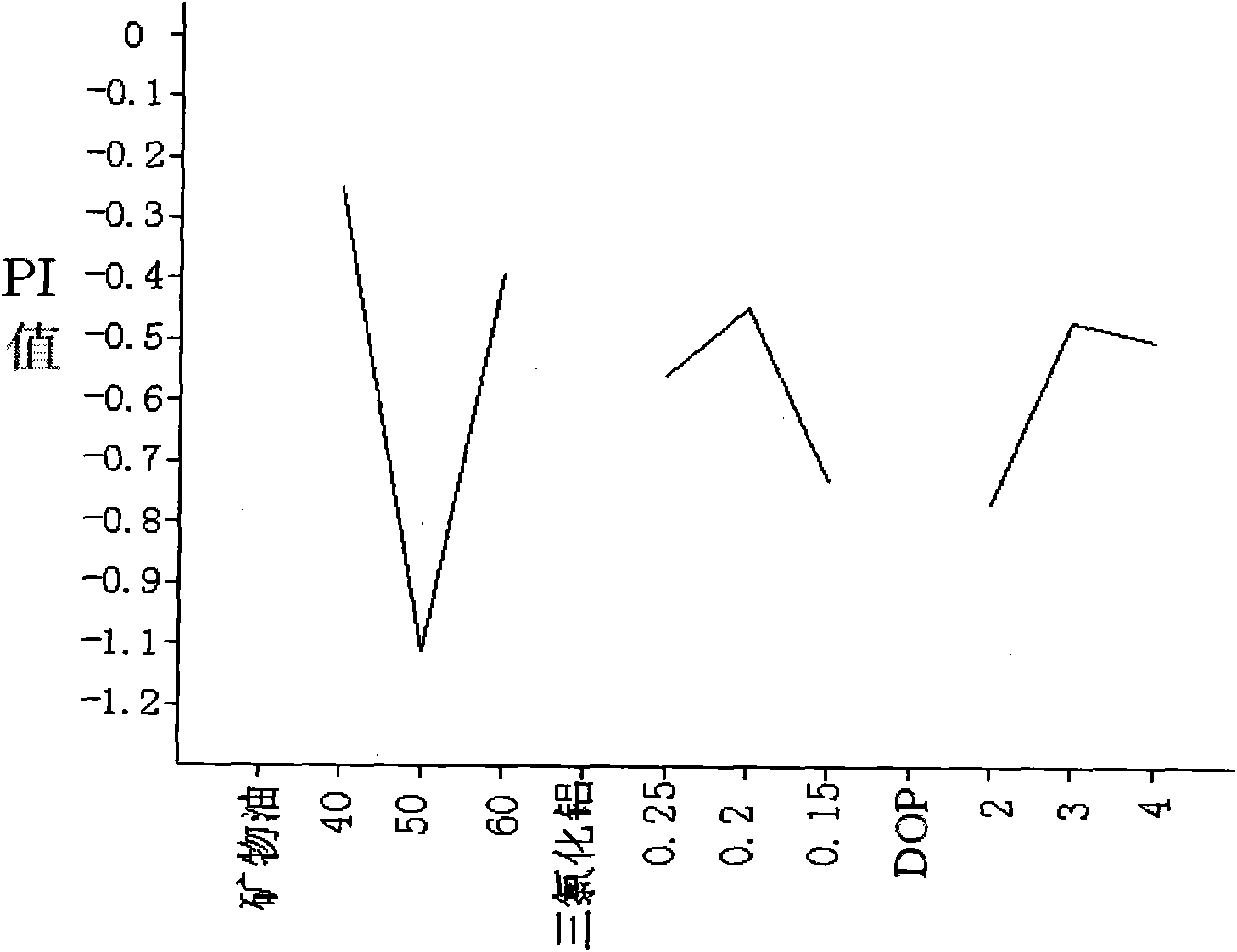

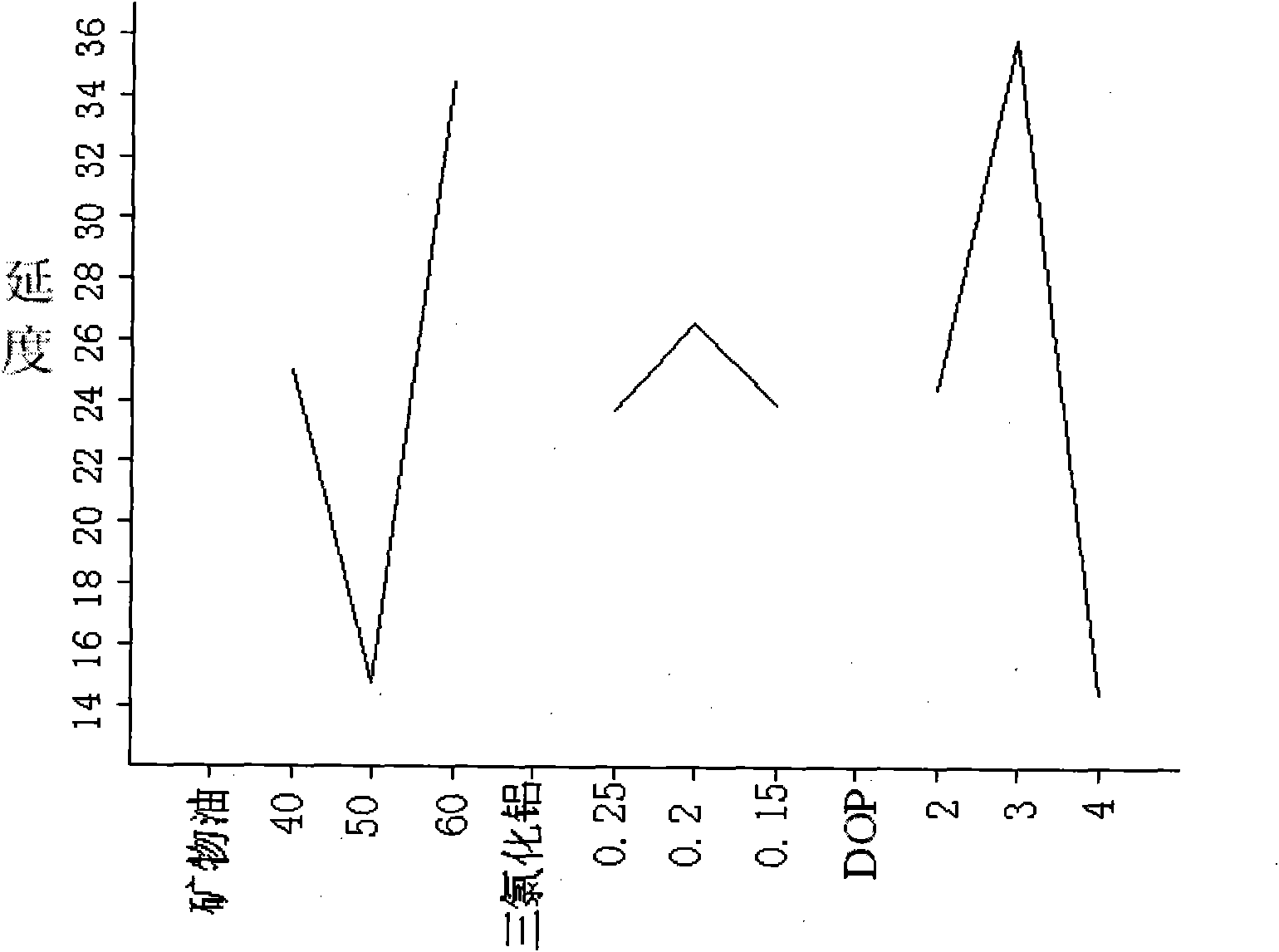

The invention discloses a thermal regenerant for an asphalt concrete pavement, which is prepared form the following components in parts by weight: 40 to 60 parts of tung oil, 0.15 to 0.25 part of anhydrous AlCl3 and 2 to 4 parts of dimethyl phthalate. The invention also discloses a preparation method of the thermal regenerant, comprising the following steps: firstly dissolving the anhydrous AlCl3with anhydrous ethanol; adding the dissolved anhydrous AlCl3 into the tung oil and uniformly stirring to obtain the tung oil mixed solution; and finally, adding DOP into the tung oil mixed solution, carrying out reaction under 240 DEG C for 15 min to obtain the thermal regenerant. The invention overcomes the disadvantages of low utilization ratio, long construction period, low construction quality, poor stability of regenerant and high processing cost of an old asphalt pavement in the prior pavement regeneration technology.

Owner:天津市大港公路处

Regenerant for aged asphalt and preparation method thereof

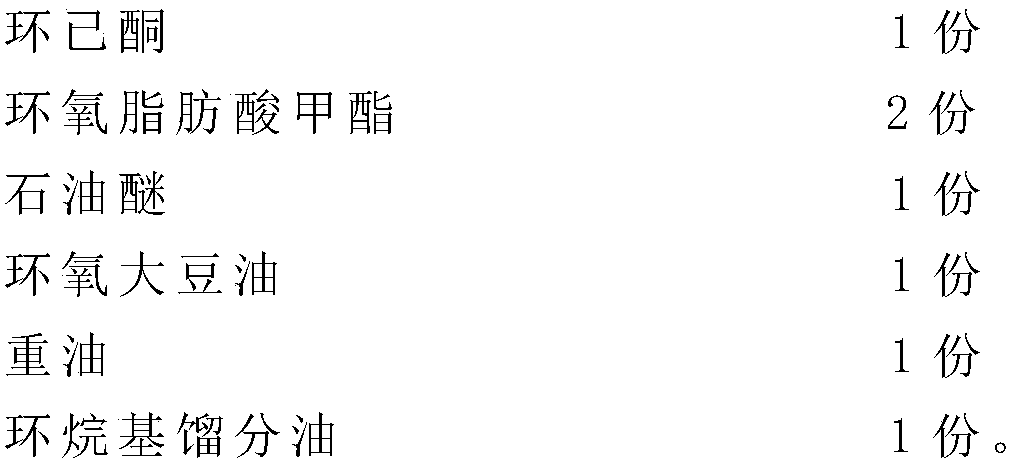

InactiveCN109021599AImprove solubilityImprove softening effectPlastic/resin/waxes insulatorsBuilding insulationsCyclohexanoneGlycidyl methacrylate

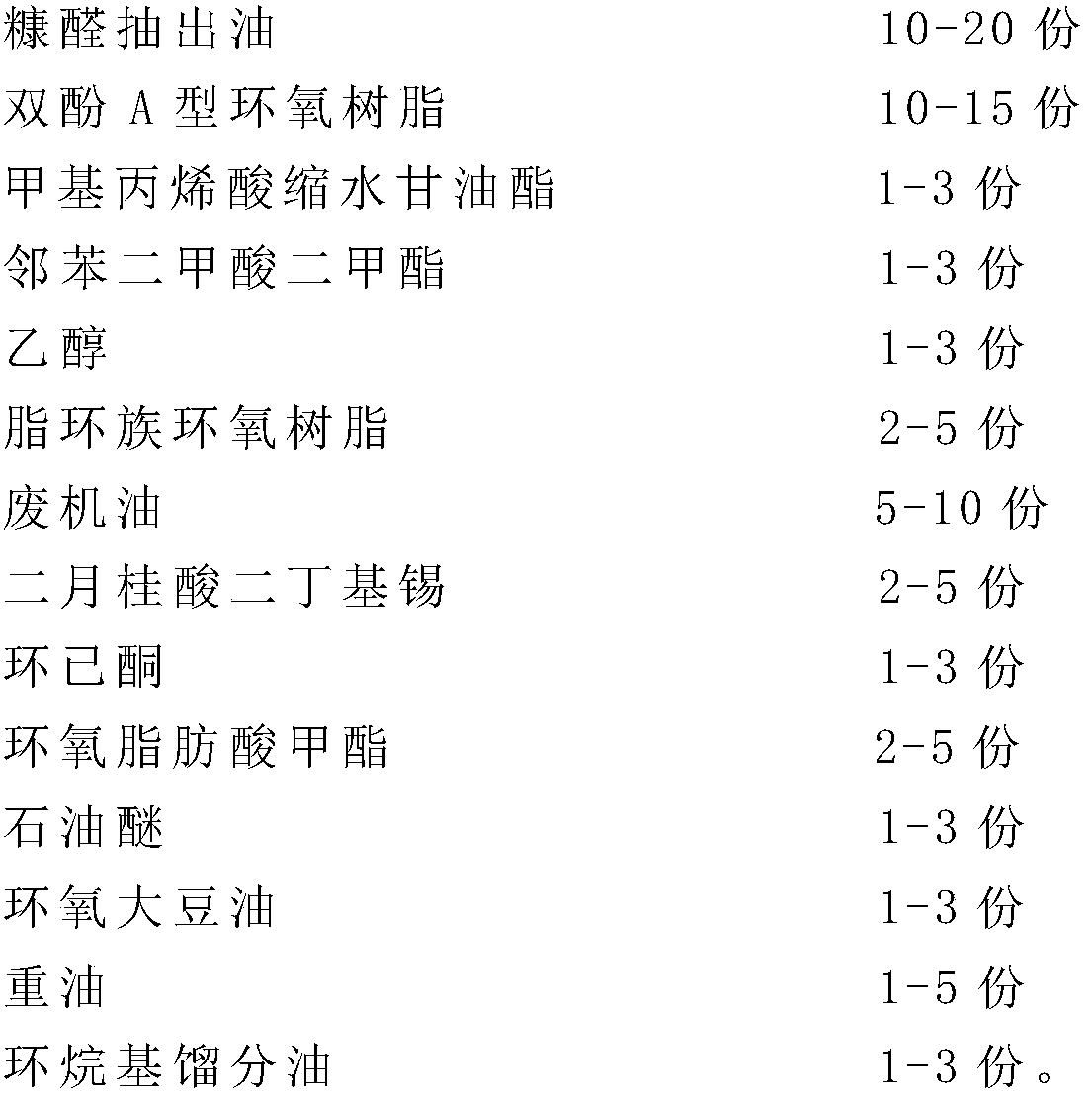

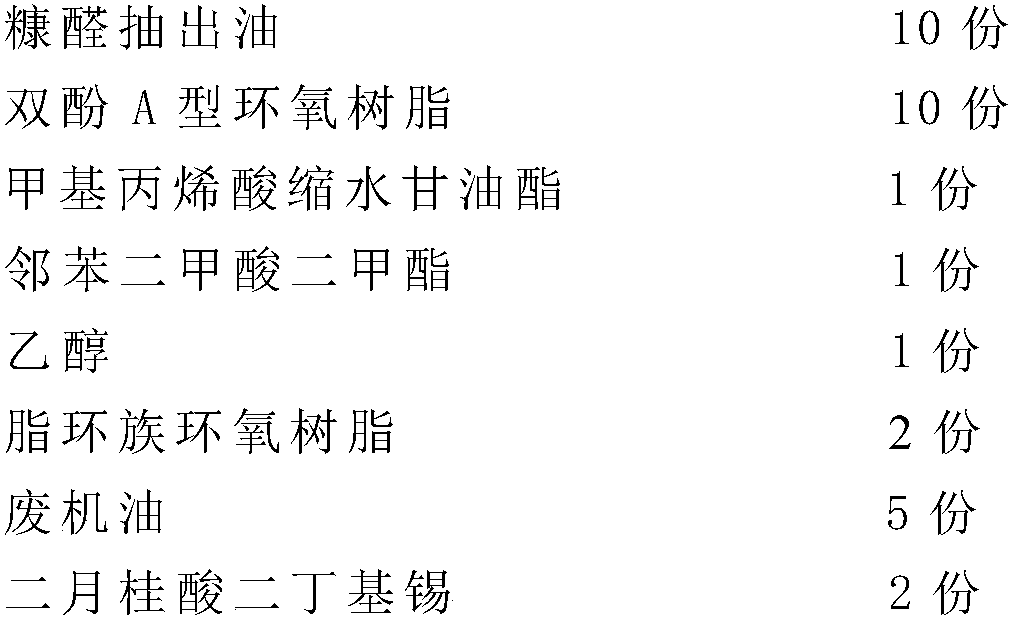

The invention discloses a regenerant for aged asphalt and a preparation method thereof, and belongs to the field of road engineering. The asphalt regenerant of the invention is composed of the following ingredients (by weight): 10-20 parts of furfural extract oil, 10-15 parts of bisphenol A epoxy resin, 1-3 parts of glycidyl methacrylate, 1-3 parts of dimethyl phthalate, 1-3 parts of ethanol, 2-5parts of alicyclic epoxy resin, 5-10 parts of used oil, 2-5 parts of dibutyltin dilaurate, 1-3 part of cyclohexanone, 2-5 parts of epoxidized fatty acid methyl ester, 1-3 parts of petroleum ether, 1-3parts of epoxidized soybean oil, 1-5 parts of heavy oil and 1-3 parts of cycloalkyl distillate. The regenerant has characteristics of high temperature performance, excellent low-temperature crack resistance and strong ageing resistance and weather resistance, and is suitable for large-scale promotion and application.

Owner:四川高路远长集团有限公司

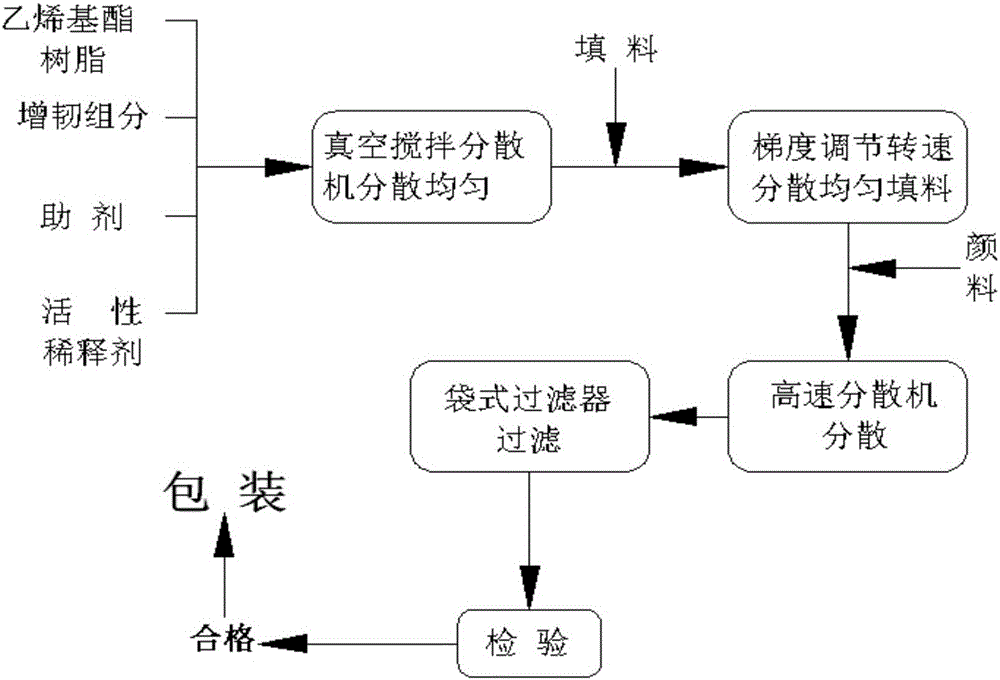

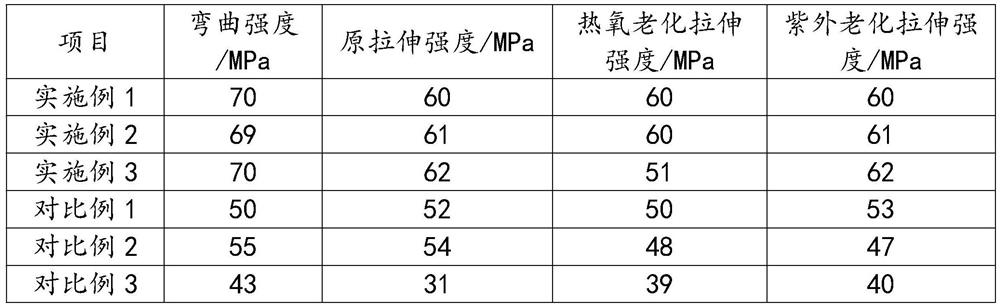

Aluminum cathode anticorrosive paint for zinc electrodeposition and preparation technique thereof

ActiveCN105969100AFlat surfaceStrong impact resistanceAnti-corrosive paintsEpoxy resin coatingsMetallurgyVinyl ester

The invention relates to an aluminum cathode anticorrosive paint for zinc electrodeposition and a preparation technique thereof. The anticorrosive paint comprises a component A, a component B and a component C. The component A comprises the following ingredients in parts by mass: 100-150 parts of vinyl ester resin, 15-25 parts of reactive diluent, 10-25 parts of toughening component, 6-12 parts of aid, 5-10 parts of pigment and 25-60 parts of filler. The component B is a solution formed by mixing cobalt naphthenate and styrene in a mass ratio of 1:1. The component C is a solution formed by mixing methylethyl ketone peroxide and dimethyl phthalate in a mass ratio of 1:(0.5-1.2). The component A, component B and component C are blended in a mass ratio of 100:(0.5-3):(1-6) to obtain the anticorrosive paint which can be constructed and used immediately. When being used as an anticorrosive coating, the paint has the advantages of excellent adhesive force, excellent impact resistance, excellent acid resistance, excellent damp heat resistance and excellent salt spray resistance, and especially has excellent permeation resistance and acid resistance.

Owner:昆明高聚科技有限公司

Light wear-resisting plastic material and preparing method thereof

InactiveCN105670084AImprove mechanical propertiesImprove toughnessPlastic materialsInjection molding machine

The invention provides a light wear-resisting plastic material and a preparing method thereof.The material is prepared through the steps that at first, gamma-aminopropyltriethoxysilane, gamma-trimethoxysilylpropanethiol, absolute ethyl alcohol and acetone are mixed and stirred through a magnetic stirring machine, then mullite powder and nanometer zinc oxide are added, and the mixture stands after being stirred, and is filtered, placed into an oven to be baked, and smashed to obtain powder; the components are mixed with polyetheretherketone, ultra-high molecular weight polyethylene, high-density polyethylene, stearamide, calcium stearate, vinyltriethoxysilane, dibutyl phthalate, dimethyl phthalate and isoamyl alcohol, dispersed through a high-speed dispersing machine, placed into the oven to be baked, then smashed, added into a double-screw extruder to be extruded and palletized, and finally loaded into an injection molding machine to be molded in an injection mode, so that the material is obtained.The light wear-resisting plastic material has the very good mechanical performance, the very good toughness and the excellent wear-resisting performance.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Mosquito repellent and preparation method thereof

InactiveCN103271101AHas an antipruritic effectMosquito repellent / kill mosquito effect is goodBiocideCosmetic preparationsCypermethrinDodecylsulfonic acid

The invention belongs to the technical field of articles for daily use, and particularly relates to a mosquito repellent. The mosquito repellent is characterized by comprising the following raw materials in parts by weight: 13-18 parts of cedar wood oil, 1-3 parts of sweet basil oil,1-5 parts of linaloe wood oil, 2-6 parts of camphor, 2-6 parts of cypermethrin, 2-6 parts of allethrin, 2-6 parts of tetramethrin, 2-6 parts of dimethrin, 1-3 parts of dimethyl phthalate, 0.5-2 parts of sodium benzoate, 2-5 parts of sodium dodecyl sulfate, 0.4-3 parts of diethyl-m-toluamide, 25-40 parts of 75% alcohol, 20-45 parts of distilled water, and 0.1-1 part of essence. The invention further discloses a preparation method of the mosquito repellent. The mosquito repellent and the preparation method have the following main benefits that the application scope is wide; the mosquito repelling / killing effect is better; the keeping period is longer; the mosquito repellent has an itch relieving effect; the preparation method is simple and easy to master; and the mosquito repellent is easy to massively produce.

Owner:戴丽芬

High-tenacity automotive plastic

The invention discloses a high-tenacity automotive plastic. The high-tenacity automotive plastic is prepared from the following raw materials in parts by weight: 3-9 parts of chitosan, 5-8 parts of zirconium phosphate, 5-7 parts of polyoxyethylene ether, 2-6 parts of octanedioic acid, 4-9 parts of antimonous oxide, 1-5 parts of bamboo fibers, 6-10 parts of 3,3'-dodecyl thiodipropionate, 5-7 parts of tricresyl phosphate, 1-4 parts of dimethyl phthalate, 3-6 parts of alumina powder, 4-11 parts of PVC resin, 2-8 parts of calcium stearate, 1-3 parts of kaoline and 6-9 parts of pentaerythritol. The high-tenacity automotive plastic has the benefits of being higher in tenacity, good in mechanical property, higher in acid and alkali resistance and high in weather resistance.

Owner:青岛海蓝海洋复合功能材料科技有限公司

Wire drawing process for preparing high-toughness antioxidant PP plastic wire

The invention discloses a wire drawing process for preparing a high-toughness antioxidant PP plastic wire. The preparation method comprises the following steps: 1, preparing the following raw materials in parts by weight: 200-220 parts of polypropylene, 50-80 parts of modified basalt fibers, 20-30 parts of epoxy resin, 5-12 parts of diisopropylbenzene hydroperoxide, 10-15 parts of dimethyl phthalate, 5-10 parts of diethylenetriamine, 1-3 parts of a composite antioxidant, 1-3 parts of an initiator and 5-10 parts of a plasticizer; 2, mixing the raw materials to obtain a mixture; and 3, transferring the mixture obtained in the step 2 into a screw extruder for melt extrusion, controlling an extrusion temperature to be 270-300 DEG C and an extrusion pressure to be 2-3 bar, and conducting cooling to obtain the high-toughness antioxidant PP plastic wire. The preparation method is simple in process step, friendly to environment and free of pollution, and the modified basalt fiber and the composite antioxidant are added, so the plastic wire is endowed with high toughness and excellent oxidation resistance.

Owner:安徽昌达织物有限公司

Efficient leather brightener

InactiveCN104327745AIncrease elasticityGood oil resistancePolishing compositionsLeather surface finishingPotassium persulfateCellulose

The invention discloses an efficient leather brightener, which is prepared from the following raw materials in parts by weight: 5-10 parts of chloroprene rubber, 4-6 parts of mildew preventive, 3-9 parts of nano zinc oxide, 5-7 parts of potassium persulfate, 4-10 parts of methyl cellulose, 2-6 parts of dimethyl phthalate, 3-8 parts of polyethylene glycol, 1-4 parts of Vaseline, 2-7 parts of ethanol, 7-11 parts of epoxidized soybean oil, 4-8 parts of isooctyl polyoxyethylene ether, 1-5 parts of leather handle agent, 2-5 parts of protease, 5-9 parts of carnauba wax, 6-12 parts of fatty acid wax and 9-17 parts of modified silicon powder. The efficient leather brightener disclosed by the invention has the beneficial effects that the efficient leather brightener can enable leather to be soft, plump and good in elasticity and has a good oil-proof effect at the same time.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Novel PEEK and preparation method thereof

The invention discloses a novel PEEK and a preparation method thereof. The invention discloses a novel PEEK. The formula comprises the following raw materials, chlorinated polyvinyl chloride resin, chloroprene rubber, nitrile butadiene rubber, vinyl chloride-vinyl acetate resin, polyphenylene sulfide, polyethylene wax, dimethyl phthalate, nano boron nitride, sepiolite powder, antimonous oxide, zinc stearate, aluminum triphosphate, tungsten disulfide, copper oxide, titanium dioxide, carbon fibers, azobisisobutyronitrile, slag wool, magnesium powder, borax, magnesium hydroxide and 1,3-butanediol. The novel PEEK is prepared by the following steps: preparing a main material, preparing a modified material, mixing the main material, the modified material, zinc polyhydroxyterephthalate and butadiene styrene rubber, heating, plasticizing, extruding, calendering and the like. The novel PEEK disclosed by the invention is high in strength, strong in fire resistance, and excellent in ultraviolet resistance and acid resistance.

Owner:ZHEJIANG EXPO NEW MATERIALS CO LTD

Non-phosphorus environmental-friendly washing powder and preparation method thereof

InactiveCN104371850AHigh densityReduce packaging costsInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsFatty alcoholSodium sulfate

The invention provides non-phosphorus environmental-friendly washing powder and a preparation method thereof. The non-phosphorus environmental-friendly washing powder comprises the following raw materials in parts by weight: 2-8 parts of tallow fatty alcohol polyoxyethylene ether, 15-28 parts of edetic acid, 0.8-2.2 parts of sodium dodecyl benzene sulfonate, 13-23 parts of sodium succinate, 5-14 parts of sodium silicate, 20-30 parts of zeolite, 1-3 parts of sodium perborate, 0.6-2 parts of dimethyl phthalate, 3-8 parts of sodium sulfafe decahydrate, 2-7 parts of sodium citrate, 1-5 parts of sodium sulfosuccinate diester and 4-11 parts of naphtha. The non-phosphorus environmental-friendly washing powder provided by the invention does not contain any environmentally harmful substance, is high in density and cleaning speed and good in effect.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

A fireproof coating for lithium-ion power battery pack and preparation method thereof

ActiveCN108165126BSuitable for large-scale productionImprove performanceFireproof paintsEpoxyDimethylaniline N-oxide

The invention belongs to the technical field of lithium ion battery, and in particular, relates to a fireproof coating layer for a lithium ion power battery pack and a preparation method thereof. Thefireproof coating layer consists of the following components by the weight percentage: 15 to 55% of sodium phosphate, 5% to 15% of modified amino resin, 2 to 6% of titanium dioxide, 2 to 8% of dimethyl phthalate, 1 to 5% of dimethylaniline, 1 to 5% of epoxy chloroethane, and 30 to 70% of a solvent. Compared with the prior art, the inner wall or an outer shell of the battery pack is coated with thespecially prepared fireproof coating layer, therefore, when the battery pack is burned, the fireproof coating layer can isolate the battery pack and a shell body for as long as two hours or more under a condition of open fire, the combustion is prevented from spreading quickly to other parts of a vehicle, enough time is left for the personnel on the vehicle to safely withdraw, malignant personnelcasualty accidents are avoided from being generated and the safety performance of the lithium ion battery pack is effectively improved.

Owner:DONGGUAN LILONG BATTERY TECH CO LTD

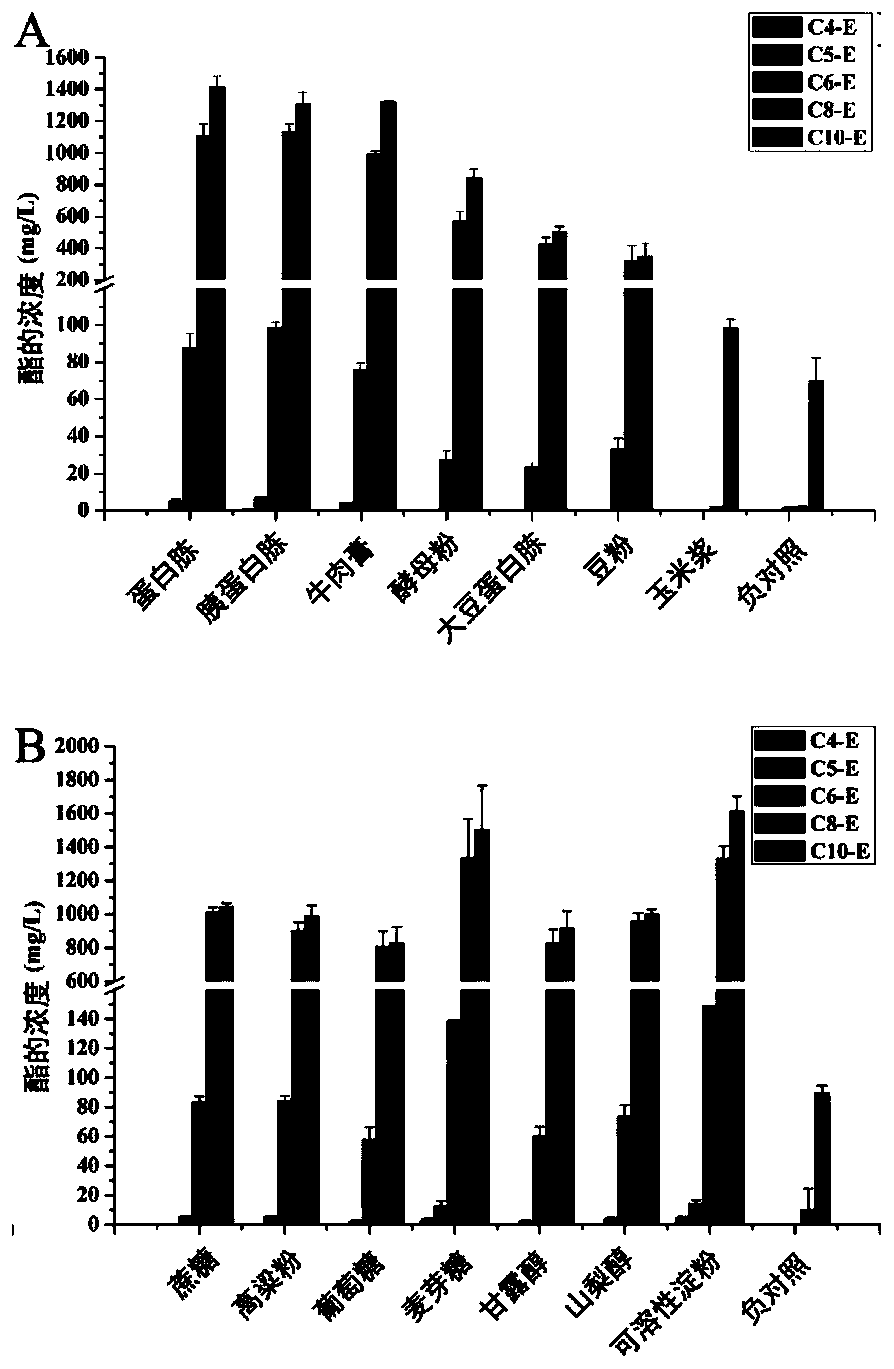

Culture method of burkholderia cepacia and application thereof in catalytic synthesis of flavor esters of baijiu and degradation of harmful esters of baijiu

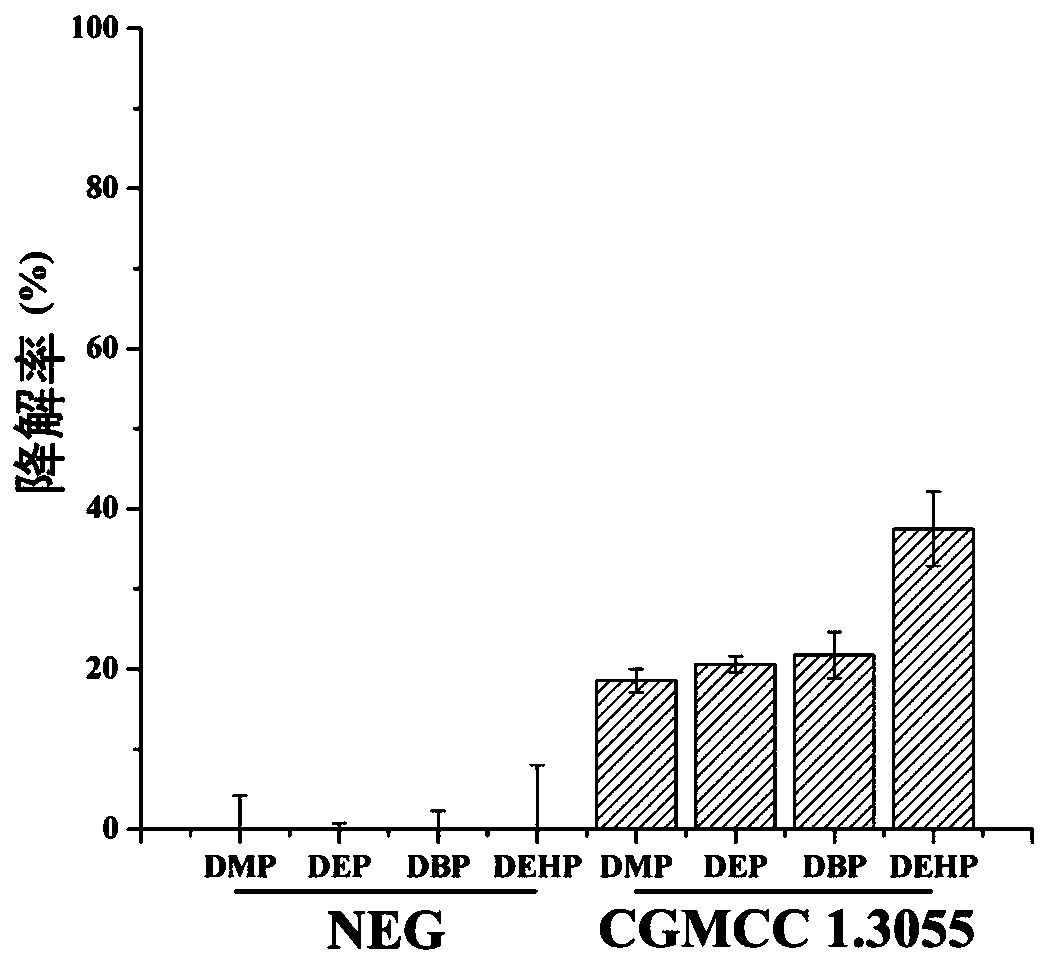

ActiveCN110484574APromote degradationAlcoholic beverage preparationMicroorganism based processesMicroorganismEthyl butyrate

The invention belongs to the technical field of microbes and particularly discloses a culture method of burkholderia cepacia CGMCC1.3055 and application thereof in catalytic synthesis of a flavor esters of baijiu and degradation of harmful esters of baijiu. The burkholderia cepacia CGMCC1.3055 has the capacity of efficiently catalyzing and synthesizing baijiu flavor esters ethyl butyrate, ethyl valerate, ethyl hexanoate, ethyl octanoate and ethyl decanoate in a water phase system and degrading harmful baijiu esters dimethyl phthalate (DMP), diethyl phthalate (DEP), dibutyl phthalate (DBP) andphthalic acid bis(2-ethylhexanoic) ester (DEHP), the yields of the flavor esters are 4.26+ / -1.21, 14.42+ / -2.42, 148.91+ / -15.60, 1331.34+ / -75.33 and 1610.89+ / -90.31 mg / L respectively, and the degradation rates of the harmful esters are 18.56%+ / -1.46%, 20.62%+ / -1.00%, 21.76%+ / -2.89% and 37.52%+ / -4.65% respectively.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Multi-element ion antibacterial macromolecular material additive

InactiveCN106832756AImprove antibacterial propertiesExtended service lifeBiocideDead animal preservationElectromagnetic fieldStearic acid

The invention relates to a multi-element ion antibacterial macromolecular material additive. The multi-element ion antibacterial macromolecular material additive is prepared from the following raw materials in parts by weight: 200 to 500 parts of phenolic resin, 50 to 100 parts of dimethyl phthalate, 70 to 80 parts of stearic acid, 70 to 80 parts of multi-element ion antibacterial agent, 70 to 80 parts of acidified talcum powder, and 70 to 80 parts of water. The multi-element ion antibacterial macromolecular material additive has the advantages that by utilizing the ion antibacterial principle and the micro-electromagnetic field technique principle, a novel high-efficiency antibacterial adding material is prepared; the antibacterial property of the matrix material is effectively improved, the service life is prolonged, the problems of low antibacterial property, short service life, overhigh temperature dependence and the like of the traditional antibacterial material are solved, and the common electromagnetic matrix material meets the social requirements.

Owner:ZHEJIANG WATERHOR ENVIRONMENTAL PROTECTION TECH CO LTD

Cleaning type internal combustion engine lubricating oil

Disclosed is cleaning type internal combustion engine lubricating oil. The cleaning type internal combustion engine lubricating oil comprises, by weight, 6-14 parts of lupeol palmitate, 3-7 parts of antioxidant, 4-9 parts of monopotassium phosphate, 4-6 parts of bisphenol A polycarbonate, 3-5 parts of citric acid mono-methyl ester, 2-6 parts of dodecanedioic acid, 7-11 parts of epoxy acrylic acid, 20-30 parts of base oil, 1-4 parts of amino phosphate, 3-10 parts of sorbitan monooleate, 2-6 parts of glycerinum monooleate, 7-11 parts of dimethyl phthalate, 2-6 parts of walnut oil and 1-2 parts of nanometer hafnium carbide powder. The cleaning type internal combustion engine lubricating oil has the advantages that the cleaning performance is excellent, accumulated carbon can be excellently cleaned, and meanwhile, certain sealing effect is achieved.

Owner:QINGDAO QIYUAN ZHENDONG ELECTRIC

Environment-friendly polyethylene resin

The invention relates to environment-friendly polyethylene resin. The environment-friendly polyethylene resin is characterized by comprising the following components: 150 parts of polyethylene, 1 part of antimony oxide, 1 part of diethyl phthalate, 5 parts of glycollic amide, 1 part of dibasic lead phosphate, 3 parts of aminopropyltriethoxysilane, 2 parts of diphenylamine, 2 parts of dimethyl phthalate, 4 parts of talcum powder, 1 part of trimethylol ethane, 2 parts of pentaerythritol and 2 parts of divinyl benzene. The environment-friendly polyethylene resin further comprises 8 parts of calcium stearate. According to the environment-friendly polyethylene resin, recycled waste plastic is used as a raw material and engineering plastic with high tensile strength, toughness and fire resistance can be produced; and the production cost can be reduced, resources are saved and a certain promotion effect on environmental protection is realized.

Owner:QINGDAO DTCN NEW MATERIAL TECH DEV

Antibacterial hard Teflon plastic

The invention discloses an antibacterial hard Teflon plastic which comprises, by weight, 0.5-0.8 part of polyvinylidene fluoride, 1-5 parts of emery powder, 0.3-0.8 part of caprolactam enclosed aromatic polyisocyanate, 0.6-1.0 part of dibutyl phthalate, 2-5 parts of Teflon, 0.1-2.0 parts of dimethyl phthalate, 1-4 parts of ethylene, 0.5-3.0 parts of ethylene-vinyl alcohol copolymer, 0.1-0.4 part of dibasic lead phosphite, 0.5-5.0 parts of tribasic lead stearate, 0.1-0.4 part of aluminum oxide powder, 3-6 parts of carbon micro-powder, 0.1-0.4 part of silicon dioxide and 0.5-0.8 part of methylbenzene. By the mode, the antibacterial hard Teflon plastic is low in density, high in impact resistance, convenient to process, good in quality and long in service life, is a functional plastic with good functionality and occupies an important place in the market.

Owner:SUZHOU NEW DISTRICT TEFLON PLASTIC PRODS FACTORY

Dimethyl phthalate production process

ActiveCN113061085AHigh esterification rateHigh yieldPhysical/chemical process catalystsOrganic compound preparationPtru catalystProcess engineering

The invention relates to a dimethyl phthalate production process which comprises the following steps: S1, adding phthalic anhydride and methanol into an esterification reaction tower through a reaction pump, and adding a catalyst for esterification reaction to obtain a dimethyl phthalate crude product; s2, adding the dimethyl phthalate crude product into an alkali washing tank for alkali washing; s3, adding the dimethyl phthalate crude product subjected to alkali washing into a water washing tank for water washing; s3, adding the washed dimethyl phthalate crude product into a dehydration tower for dehydration; and S4, adding the dehydrated dimethyl phthalate crude product into a rectifying tower, and rectifying to obtain the product. The dimethyl phthalate is synthesized from phthalic anhydride and methanol, SO4 < 2-> / Zr02-CeO2 and Sb2O3 / ZrO2 / zeolite are synergistically used as the catalyst, the dimethyl phthalate is synthesized through rectification, and the method has the advantages of being high in esterification rate, good in selectivity, high in yield and reusable in catalyst.

Owner:RUNTAI CHEM CO LTD

Antistatic Teflon engineering plastic

The invention discloses antistatic Teflon engineering plastic. The antistatic Teflon engineering plastic is prepared from the following raw materials in parts by weight according to calculation in percentage by mass: 1 to 6 parts of polyvinylidene fluoride, 0.5 to 3 parts of polytetrafluoroethylene, 2 to 5 parts of corindon powder, 0.1 to 0.6 part of dibutyl phthalate, 6 to 9 parts of hexamethylene diisocyanate, 0.4 to 0.9 part of dimethyl phthalate, 3 to 6 parts of ethylene, 1 to 6 parts of polyethylene, 2 to 5 parts of an ethylene-vinyl alcohol copolymer, 1 to 3 parts of dibasic lead phosphite and 0.6 to 0.8 part of an anti-cation internal mixing type antistatic agent. With the adoption of the manner, the antistatic Teflon engineering plastic disclosed by the invention is small in density, great in anti-impact strength, convenient to machine, good in quality and long in service life, is functional plastic with good functionality and occupies an important position in the market.

Owner:SUZHOU NEW DISTRICT TEFLON PLASTIC PRODS FACTORY

Protective film production process

InactiveCN113105835AImprove ductilityIncrease internal stressFilm/foil adhesive primer layersEpoxyPolymer science

The invention discloses a protective film production process, and relates to the technical field of polymer protective films. The protective film production process mainly comprises the following steps: 1, respectively adding liquid silica gel, epoxy resin, dimethyl phthalate, a coupling agent and silicone oil into a reaction kettle, and stirring in a negative pressure environment with the temperature controlled to be 30-35 DEG C to obtain a mixed raw material A; 2, treating the seamless melt adhesive film in an environment at 120-150 DEG C, and then coating the surface of the seamless melt adhesive film with a layer of raw adhesive filtered by a filter screen; and step 3, uniformly coating the mixed raw material A on the seamless melt adhesive film treated by the raw adhesive, wherein the coating thickness is controlled to be 4-8 threads. The ductility of the whole prepared protective film is improved by adding the plasticizer dimethyl phthalate into the raw materials of the production process of the protective film, and the internal stress of the protective film is eliminated by performing stress elimination treatment on a finished product for a period of time by using a drying oven after the finished product of the protective film is produced.

Owner:ZHEJIANG HISEA TECH CO LTD

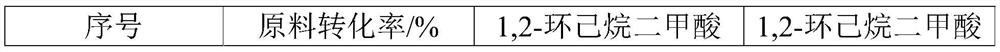

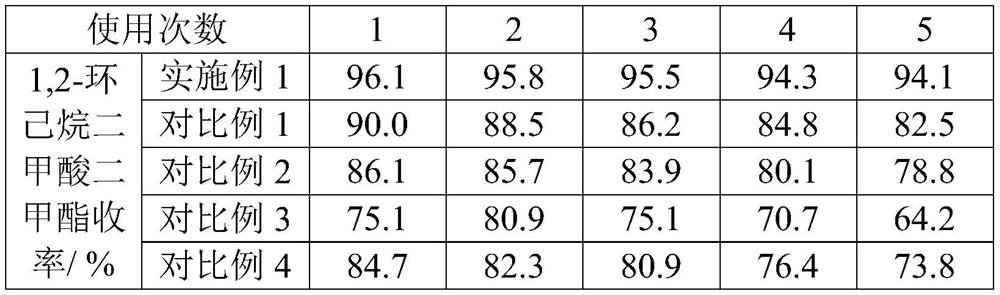

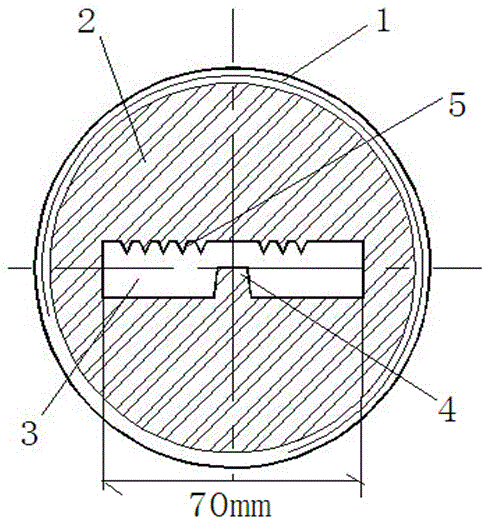

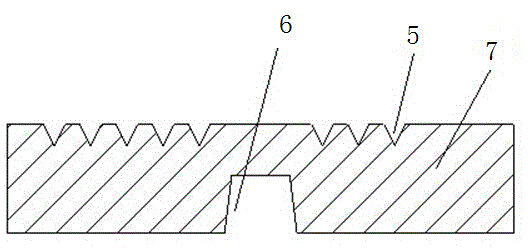

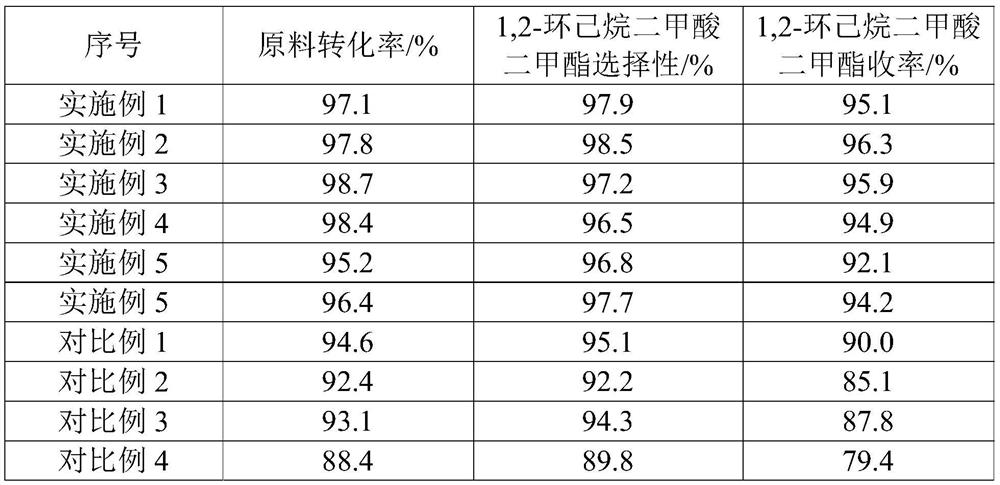

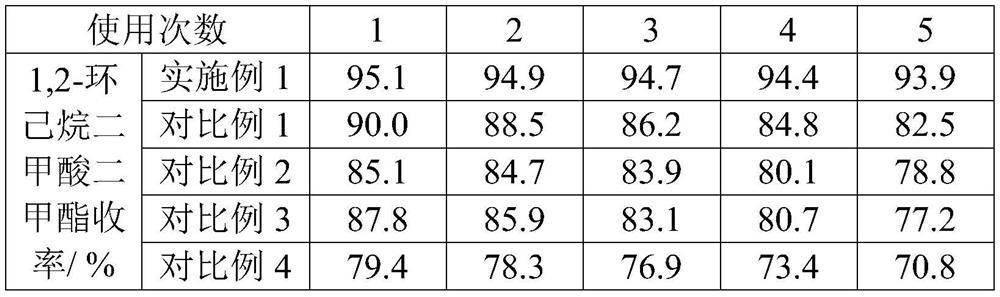

Preparation method and application of monatomic catalyst for synthesizing dimethyl 1,2-cyclohexanedicarboxylate from dimethyl phthalate

PendingCN113680370AStrong acid and alkali resistanceLarge specific surface areaCatalyst carriersMolecular sieve catalystsPtru catalystPhthalic acid

The invention belongs to the field of preparation of catalysts, and particularly relates to a preparation method and application of a monatomic catalyst for synthesizing dimethyl 1,2-cyclohexanedicarboxylate from dimethyl phthalate. Nitrogen-doped carbon nanotubes prepared by an improved chemical vapor deposition method are used as a carrier; and the M / nitrogen-doped carbon nanotube monatomic catalyst (M=Pd, Ni, Ru) is prepared by an impregnation method. The preparation method is simple, and the M / nitrogen-doped carbon nanotube monatomic catalyst has the advantages of large specific surface area, high mechanical strength, small mass transfer limit, more uniform dispersion of metal active components on the surface of the carrier and the like, has high atom utilization rate and longer service life, and is used for hydrogenation synthesis reaction of dimethyl 1,2-cyclohexanedicarboxylate from dimethyl phthalate, and the reaction activity of the catalyst and the selectivity of the dimethyl 1,2-cyclohexanedicarboxylate are obviously improved.

Owner:RUNTAI CHEM TAIXING CO LTD

Preparation method and construction method of PVC (polyvinyl chloride) soft plastic water drip

The invention relates to a preparation method and construction method of a PVC (polyvinyl chloride) soft plastic water drip, belonging to the field of construction. The preparation method comprises the following steps: proportioning, mixing, forming, setting, drawing, and cutting to obtain the finished product. The PVC soft plastic water drip comprises 100kg of polyvinyl chloride resin, 22-28kg of dimethyl phthalate, 16-22kg of dibutyl phthalate, 1-5kg of toughener, 5-10kg of light calcium carbonate, 2-5kg of heat-resistant agent, 1-2kg of barium stearate, 0.5-1kg of cadmium stearate, 1-2kg of paraffin and 0.1-0.5kg of ultraviolet absorbent. The method solves the problem of great construction difficulty, time consuming, labor consuming and difficulty in ensuring appearance quality in the cement mortar water drip in construction engineering.

Owner:SHANXI ERJIAN GRP

Environment-friendly wood floor adhesive

InactiveCN105969215AStrong water and moisture resistanceHarm reductionNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveXylylenePolyethylene oxide

The invention discloses environment-friendly wood floor adhesive. The environment-friendly wood floor adhesive comprises, by weight, 11-17 parts of organic silicon resin, 2-3 parts of organic silicon defoaming agents, 1.5-3.2 parts of alkylphenol polyethylene oxide ether, 1-2.4 parts of dimethyl phthalate, 6-8 parts of butyl acrylate, 3.5-6.4 parts of methacrylic acid isocyanide acyl ethyl ether, 15-18 parts of starch glue, 3-6 parts of polyhexylene glycol decanedicarboxylate, 0.5-2 parts of isodecanol polyoxyethylene ether, 6-10 parts of locust glue etherification substances, 1.2-2.5 parts of sodium xylene sulfonate, 6.3-8 parts of nanometer vermiculite, 0.5-1.4 parts of parachlorometaxylenol and 1.2-1.6 parts of titanate. The environment-friendly wood floor adhesive has the advantages that the environment-friendly wood floor adhesive is low in toxicity, little in harm to environments and human bodies and high in water resistance and moisture resistance, and adhesion effects can be effectively realized.

Owner:青岛特澳能源检测有限公司

Composite light energy-saving thermal-insulation material and preparation method thereof

InactiveCN105110753AImprove insulation effectReduce weightSolid waste managementCalcium silicateThermal insulation

The invention discloses a composite light energy-saving thermal-insulation material and a preparation method thereof. The preparation method comprises 1, respectively crushing diatomite, meerschaum powder and calcium carbide, 2, respectively weighing 4-12 parts by weight of micro-porous calcium silicate, 4-9 parts by weight of alumina silicate fibers, 5-12 parts by weight of diatomite, 2-6 parts by weight of meerschaum powder and 3-6 parts by weight of calcium carbide, and carrying out mechanical stirring to obtain a uniform mixture, 3, adding 6-15 parts of polyamide 610, 3-8 parts of jute fibers, 4-9 parts of Teflon, 3-7 parts of dimethyl phthalate and 4-10 parts of polytrimethylene terephthalate fibers into the mixed powder obtained by the step 2, and carrying out heating stirring, and 4, carrying out pressing molding on the mixed materials, and then carrying out cooling to a room temperature so that the composite light energy-saving thermal-insulation material is obtained. The composite light energy-saving thermal-insulation material has the characteristics of light weight, compression resistance and thermal insulation.

Owner:SUZHOU KEMIAO NEW MATERIAL

Stable asphalt pavement material

InactiveCN105968844AImprove stabilityStable temperatureBuilding insulationsAluminum StearateCross linker

The invention relates to a stable asphalt pavement material. The stable asphalt pavement material is prepared by, by weight, 0.2-0.5 part of diphenylamine, 0.23-0.4 part of crosslinking agent, 20-36 parts of base asphalt, 0.4-0.7 part of Arabic gum, 6-10 parts of sodium lauryl alcohol polyoxyethylene ether sulfate, 0.8-2.4 parts of dimethyl phthalate, 1-1.7 parts of phenol, 0.4-1.2 parts of triethoxy silane, 0.5-1.4 parts of dispersing agent, 6-9 parts of adhering auxiliaries, 2-4 parts of potassium chloride, 5-8 parts of aluminum stearate, 6-9 parts of water-based acrylic emulsion, 4-7 parts of preservatives and 6-10 parts of polyisobutene. The stable asphalt pavement material has temperature stability and is resistant to low-temperature cracking and traveling vehicle damage, good in deformation resistance and extremely good in stability.

Owner:青岛千帆高新技术有限公司

Ink for metal packaging containers and preparation method thereof

InactiveCN105176183AImprove corrosion resistanceImprove aging resistanceInksAnti-corrosive paintsManganeseMelamine formaldehyde resin

The invention relates to an ink for metal packaging containers and a preparation method thereof. The ink contains the following components in parts by mass: 50-60 parts of resin oil, 4-15 parts of melamine formaldehyde resin, 10-20 parts of butyl lactate, 15-25 parts of permanent red, 1-4 parts of Yintiebao red, 2-5 parts of soft phospholipid, 0.5-1.8 parts of organobentonite, 1-3 parts of manganese naphthenate, 0.6-1.6 parts of acetanilide, 0.5-1.5 parts of p-toluenesulfonic acid, 1-3 parts of dimethyl phthalate and 3-7 parts of eugenol. The ink provided by the invention has the advantages of excellent corrosion resistance, excellent erosion resistance and excellent aging resistance; after being applied onto the metal packaging container surface, the ink can not be easily corroded by chemicals and can not be easily aged after long-time insolation in the sun; and thus, the ink has long service life.

Owner:SUZHOU DINGLI PACKAGING

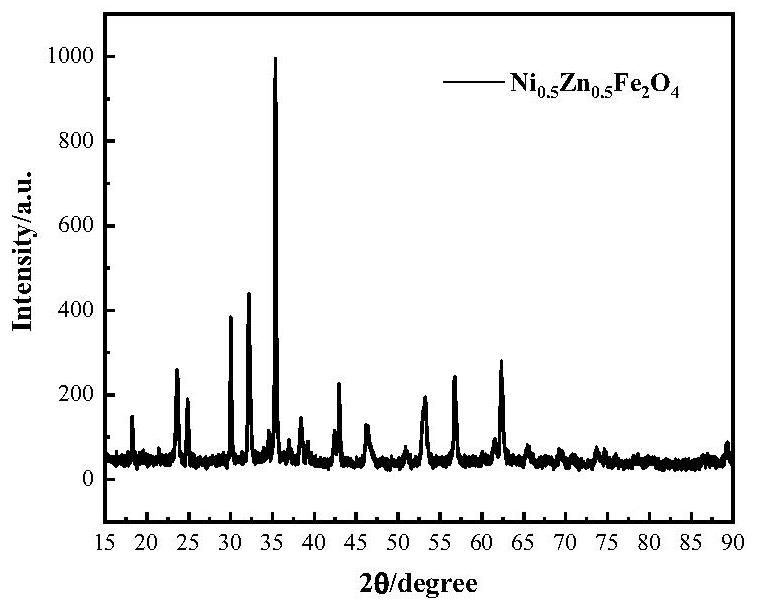

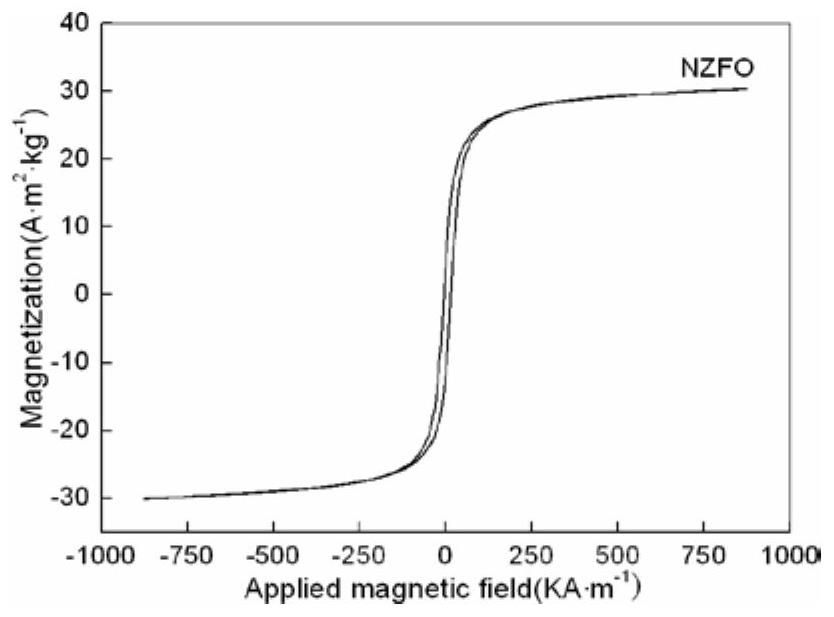

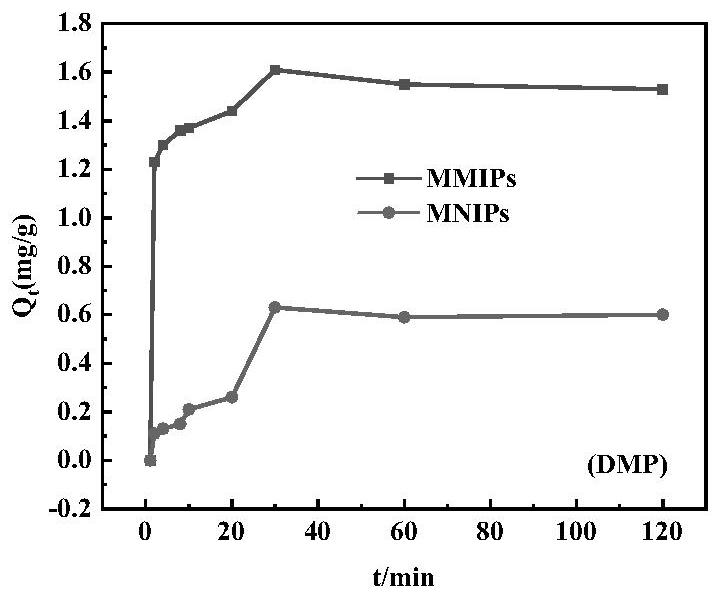

Preparation method of phthalate magnetic molecularly imprinted polymer extraction material

The invention belongs to the new technical field of sample pretreatment and enrichment, and provides a preparation method of a dimethyl phthalate magnetic molecularly imprinted polymer extraction material, which comprises the following steps: preparing a Ni0. 5Zn0. 5Fe2O4 magnetic core by adopting a hydrothermal method, modifying the magnetic core by using tetraethoxysilane (TEOS) and 3-(methacryloyloxy) propyltrimethoxysilane (MPS), and preparing the dimethyl phthalate magnetic molecularly imprinted polymer extraction material. Then preparing phthalate magnetic template molecularly imprinted polymers (DMP-MMIPs) by adopting a precipitation polymerization method and taking dipropyl phthalate (DPRP) as a template molecule, methacrylic acid (MAA) as a functional monomer, ethylene glycol dimethacrylate (EGDMA) as a cross-linking agent and azodiisobutyronitrile (AIBN) as an initiator; the dimethyl phthalate adsorption capacity of the prepared phthalate magnetic molecularly imprinted polymer can reach 2.50 mg / g or above, and the phthalate magnetic molecularly imprinted polymer can be applied to targeted enrichment and extraction of phthalate organic matters in an environmental water sample.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

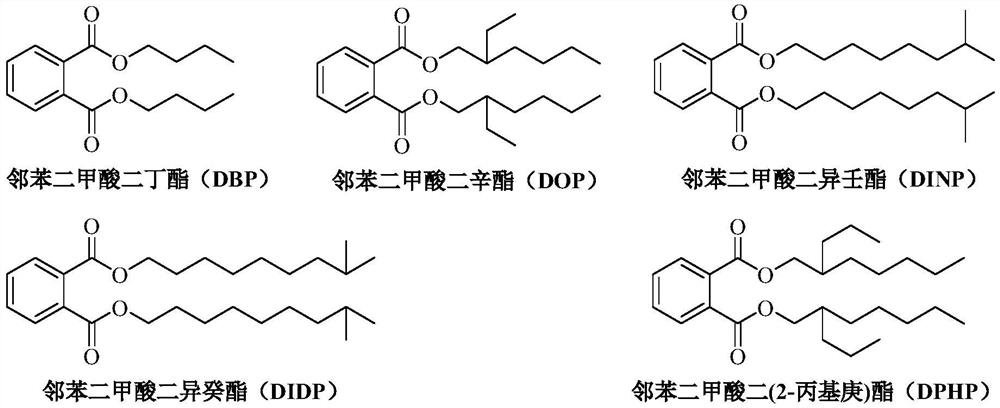

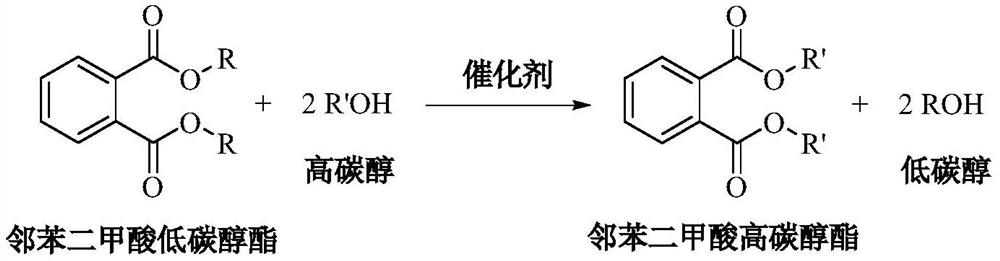

A kind of method for transesterification continuous reaction to prepare higher carbon alcohol phthalate

ActiveCN108976117BGood storage and transportation stabilityReduce consumptionPreparation by ester-hydroxy reactionHeterogenous catalyst chemical elementsHeptyl alcoholPtru catalyst

The invention relates to a method for preparing higher alcohol phthalate through continuous transesterification reaction. In a fixed-bed reactor, dimethyl phthalate, diethyl phthalate, diphthalate Low-carbon alcohols such as butyl phthalate and high-carbon alcohols such as isononanol, isodecyl alcohol, and 2-propylheptanol are used as raw materials, and magnesium calcium aluminate, sodium aluminosilicate, potassium aluminosilicate, silicon One or more of magnesium aluminate, calcium aluminosilicate, aluminum magnesium titanate, magnesium calcium titanate, and aluminum magnesium zirconate are catalysts, and the molar ratio of higher alcohol to lower alcohol phthalate is 2.1-4.0 , reaction temperature 160~220℃, volume space velocity 0.5~2h ‑1 , The conversion rate of low-carbon alcohol phthalate and the selectivity of high-carbon alcohol phthalate are above 99%. The invention has the following advantages: good stability of raw material storage and transportation, convenient feeding; less side reactions, low raw material consumption; no corrosion of the catalyst and continuous use; clean and energy-saving process, no waste water generation and discharge; reaction in a fixed bed reactor Continuous, high efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method of producing dimethyl phthalate from naphthalene based chemicals

InactiveUS20040215035A1Organic compound preparationCarboxylic acid esters separation/purificationBenzenePtru catalyst

The present invention results to an improved and environment friendly method of producing dimethyl phthalate of about 99% purity from naphthalene based chemicals, said method comprising steps of mixing phthalic anhydride with methanol in the ratio ranging between 2:3 to 3:2, adding catalyst(s) to the mixture wherein, the ratio of phthalic anhydride and the catalyst is ranging between 3:1 to 15:1, adding a promoter to the resultant of step (b) wherein, the promoter is in the range of 1.5 to 2.0% by weight of phthalic anhydride, refluxing the resulted mixture at a temperature ranging between 60 to 100° C., for time duration ranging between 6 to 12 hrs. in the presence of benzene, wherein the ratio of benzene phthalic anhydride is in the range of 1:5 to 2:1 to obtain distillate, neutralizing the residue with about 10% caustic soda, extracting the neutralized residue with the benzene, distilling at the temperature ranging between 140 to 150° C. under 10 mm of mercury to obtain dimethyl phthalate.

Owner:COUNCIL OF SCI & IND RES

Application and preparation method of bimetallic catalyst for synthesizing dimethyl 1,2-cyclohexanedicarboxylate from dimethyl phthalate

InactiveCN113680371AStrong acid and alkali resistanceLarge specific surface areaPhysical/chemical process catalystsOrganic compound preparationPtru catalystMetal catalyst

The invention belongs to the field of catalyst preparation, and particularly relates to an application and a preparation method of a bimetallic catalyst for synthesizing dimethyl 1,2-cyclohexanedicarboxylate from dimethyl phthalate. An M-Ni / nitrogen-doped carbon nanotube (M=Ru, Pd) bimetallic catalyst is prepared by taking a nitrogen-doped carbon nanotube as a dispersing agent and a carrier and utilizing a couple replacement method. The catalyst prepared by the method has the advantages of large specific surface area, high mechanical strength, small mass transfer limit, more uniform dispersion of active components on the surface of the carrier and the like; the preparation method is simple and easy to implement, high in operability, available for batch preparation and small in environmental pollution, and the catalyst can be used in a reaction for hydrogenation synthesis of dimethyl 1,2-cyclohexanedicarboxylate from dimethyl phthalate; and the reaction activity of the catalyst and the selectivity of dimethyl 1,2-cyclohexanedicarboxylate are obviously improved.

Owner:RUNTAI CHEM TAIXING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com