Photocatalysis soil heavy metal restoration agent

A technology of heavy metals and remediation agents, applied in the field of soil remediation, can solve the problems of anti-oxidation system damage, soil re-pollution, failure, etc., and achieve good application prospects and the effect of thorough removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

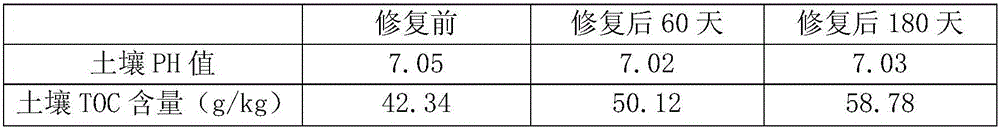

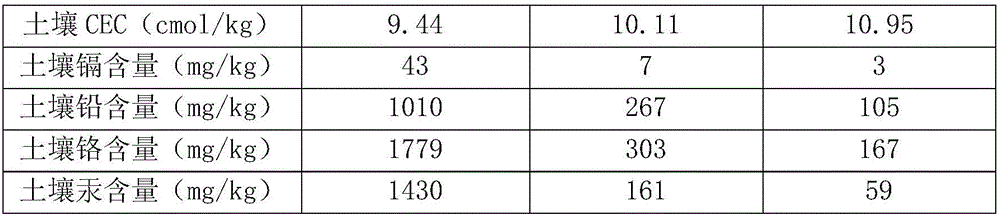

[0022] A photocatalytic soil heavy metal remediation agent, made of the following raw materials in parts by weight (kg): titanium dioxide 4, egg shell 12, calcium ammonium nitrate 5, fly ash 6, water hyacinth powder 10, potassium pyrophosphate 2, deseed Sunflower plate 85, pig manure 40, kaolin 23, calcium carbonate 12, slash pine needles 32, appropriate amount of water.

[0023] The concrete steps of the preparation of described soil heavy metal restoration agent are as follows:

[0024] (1) Dry the sunflower pan and pig manure in the sun, pulverize them, put them in an oven and dry them at 50°C for 8 hours, put the resulting slag in a closed furnace, and dry them at a speed of 20°C / min. Raise the temperature to 500°C and keep it warm for 90 minutes, then take it out when the temperature drops to 58°C to obtain biochar;

[0025] (2) Put kaolin and calcium carbonate in a calciner after being mixed, calcined at 600° C. for 40 minutes, take it out after cooling to room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com