A kind of preparation method of vanadium trioxide

The technology of vanadium trioxide and vanadium liquid is applied in the field of non-ferrous metal metallurgy, which can solve the problems of increased production cost, environmental pollution and high production cost, avoid the generation of ammonia nitrogen wastewater and ammonia gas, and reduce production cost and energy consumption cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

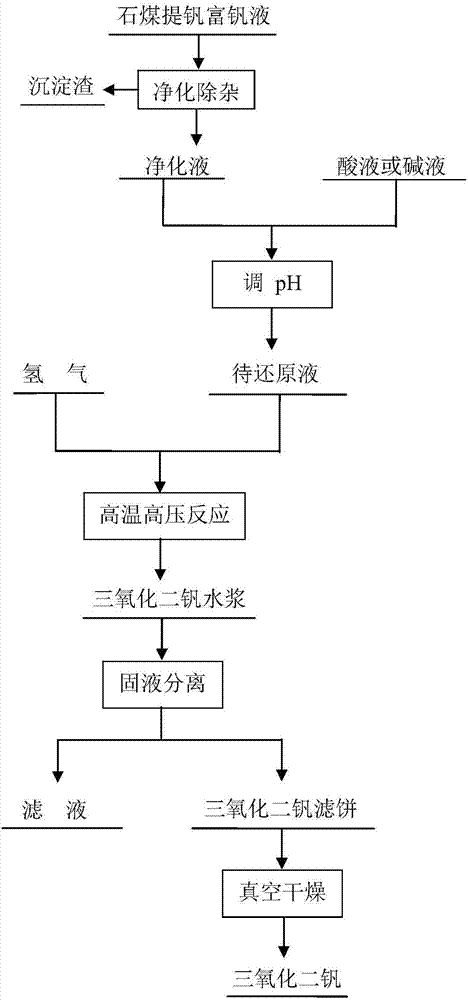

[0028] Such as figure 1 , a preparation method of vanadium trioxide, its concrete steps are:

[0029] (1) Purify and remove impurities from the vanadium-enriched liquid for extracting vanadium from stone coal with a vanadium concentration of 35-50 g / L to obtain purified liquid and precipitated slag;

[0030] (2) Use lye or acid solution to adjust the pH of the purification solution to obtain a hydrogen ion concentration of 10 -4 ~10 -7 mol / L of the solution to be reduced;

[0031] (3) Using hydrogen and the solution to be reduced at a temperature of 170-250°C, a hydrogen partial pressure of 3-4MPa, and a stirring reaction speed of 800-1000r / min, react in a high-temperature and high-pressure reactor for 3-4 hours, Obtain vanadium trioxide water slurry;

[0032] (4) vanadium trioxide water slurry is obtained vanadium trioxide filter cake and filtrate after solid-liquid separation;

[0033] (5) The vanadium trioxide filter cake is vacuum-dried to obtain vanadium trioxide.

...

Embodiment 2

[0038] A kind of preparation method of vanadium trioxide, its concrete steps are:

[0039] (1) Purify and remove impurities from the vanadium-enriched liquid for extracting vanadium from stone coal with a vanadium concentration of 15-25 g / L to obtain purified liquid and precipitated slag;

[0040] (2) Use lye or acid solution to adjust the pH of the purification solution to obtain a hydrogen ion concentration of 10 -12 ~10 -14 mol / L of the solution to be reduced;

[0041](3) Using hydrogen and the solution to be reduced at a temperature of 180-300°C, a hydrogen partial pressure of 3-5MPa, and a stirring reaction speed of 500-800r / min, react in a high-temperature and high-pressure reactor for 1-2.5 hours, Obtain vanadium trioxide water slurry;

[0042] (4) vanadium trioxide water slurry is obtained vanadium trioxide filter cake and filtrate after solid-liquid separation;

[0043] (5) The vanadium trioxide filter cake is vacuum-dried to obtain vanadium trioxide.

[0044] Th...

Embodiment 3

[0048] A kind of preparation method of vanadium trioxide, its concrete steps are:

[0049] (1) Purify and remove impurities from the vanadium-enriched liquid for extracting vanadium from stone coal with a vanadium concentration of 25 to 35 g / L to obtain purified liquid and precipitated slag;

[0050] (2) Use lye or acid solution to adjust the pH of the purification solution to obtain a hydrogen ion concentration of 10 -6 ~10 -10 mol / L of the solution to be reduced;

[0051] (3) Using hydrogen and the solution to be reduced at a temperature of 100-200°C, a hydrogen partial pressure of 2-4MPa, and a stirring reaction speed of 800-900r / min, react in a high-temperature and high-pressure reactor for 1-2 hours, Obtain vanadium trioxide water slurry;

[0052] (4) vanadium trioxide water slurry is obtained vanadium trioxide filter cake and filtrate after solid-liquid separation;

[0053] (5) The vanadium trioxide filter cake is vacuum-dried to obtain vanadium trioxide.

[0054] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com