Screening method of food hypoallergenic processing modes

A screening method and hypoallergenic technology, which can be applied in the preparation of test samples, measuring devices, material analysis by electromagnetic means, etc. Sensitivity, affecting the stability of allergens, etc., to achieve significant results, strong repeatability, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This example is an experiment aimed at the corresponding relationship between the enzymatic hydrolysis resistance band and the allergen in large yellow croaker.

[0035] 1. Extraction of protein from large yellow croaker

[0036] Take 300g of washed large yellow croaker muscle, grind the large yellow croaker muscle with a blender, then homogenize the ground fish meat with a homogenizer, add 7 times the volume of water, and adjust the pH value to about 2.4 with hydrochloric acid , to dissolve most of the protein, centrifuge at 5000r / min for 15min, and collect the supernatant. Then adjust the pH value of the supernatant to about 4.75 with sodium hydroxide solution to precipitate the protein, centrifuge at 5000r / min for 15min, collect the protein precipitate, and freeze-dry it for future use.

[0037] 2. In vitro simulated gastric juice digestion

[0038] Simulated gastric juice: Weigh 0.1g NaCl in 50ml distilled water, adjust the pH to 1.2 with HCl, add pepsin to make the...

Embodiment 2

[0055] Remove the head, tail, scales and viscera of the fresh large yellow croaker. Take 30g / bag of back white meat with skin, and 4 bags of white meat are processed as-is, steamed, boiled and baked respectively. A total of 4 groups of fish samples.

[0056] Processing as it is: Wash 30g fish meat with ice distilled water, drain, mince, put into a fresh-keeping bag and store in a -20°C refrigerator for later use.

[0057] Steam sample treatment: put 30g of washed fish meat into a boiling water steamer, and after 15 minutes from the time of putting it in, mince it, put it into a fresh-keeping bag and store it in a -20°C refrigerator for later use.

[0058] Cooking sample processing: put 30g of fish meat into a boiling water pot, and after 15 minutes from the time of putting it in, pick it up with a colander, mince it, put it into a fresh-keeping bag, and store it in a -20°C refrigerator for later use.

[0059] Baking treatment: Wrap 30g of fish flesh in tin foil, bake in an o...

Embodiment 3

[0069] Using fresh hairtail as research object, the specific processing steps are the same as in Example 2.

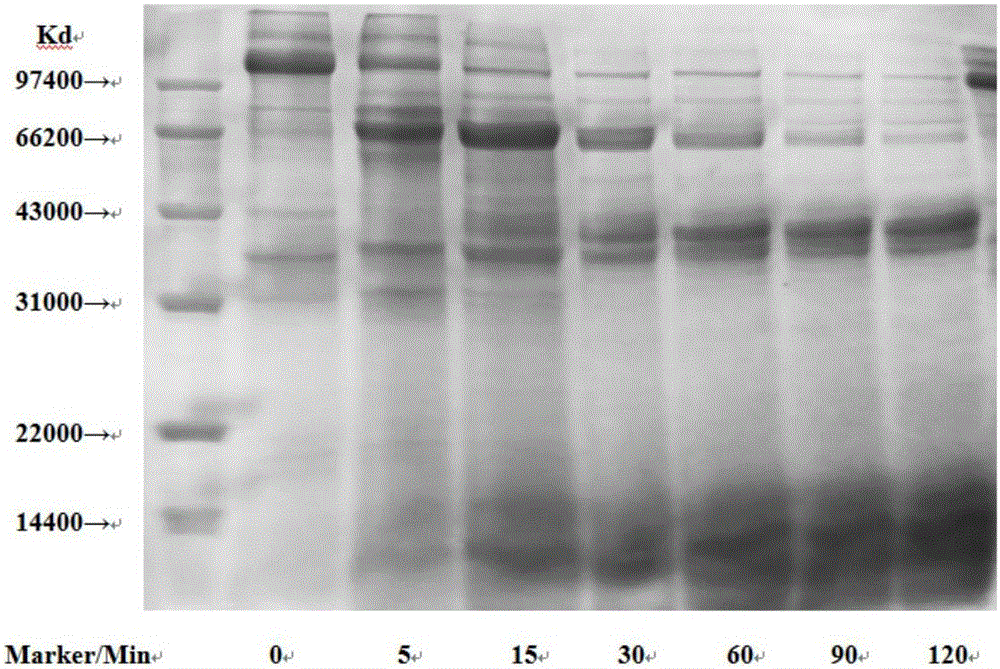

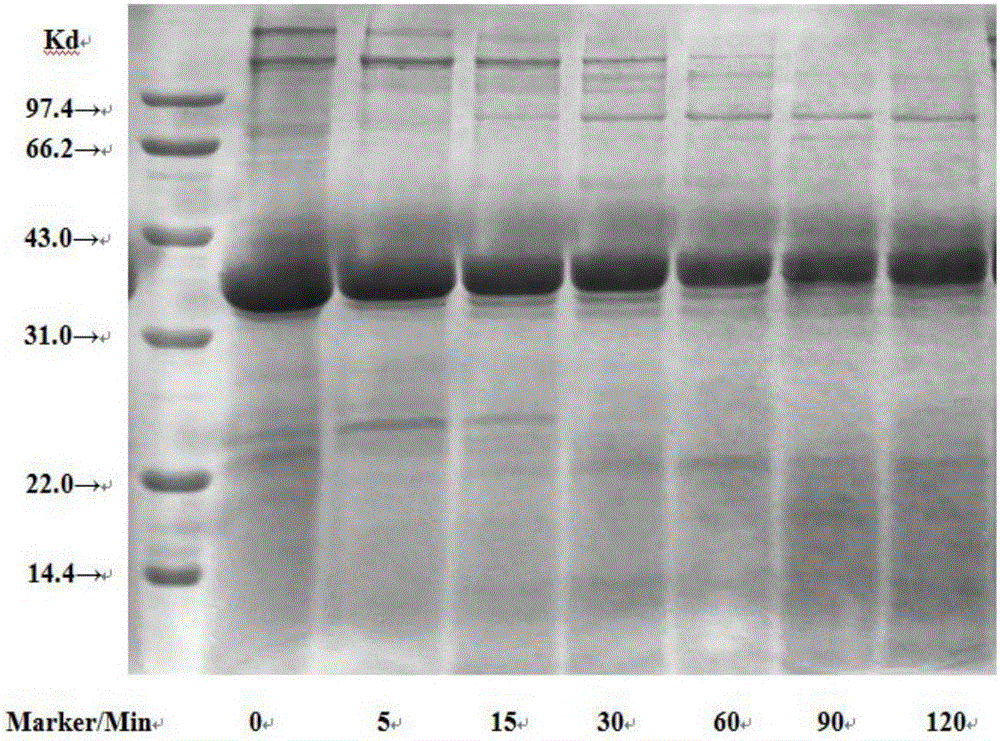

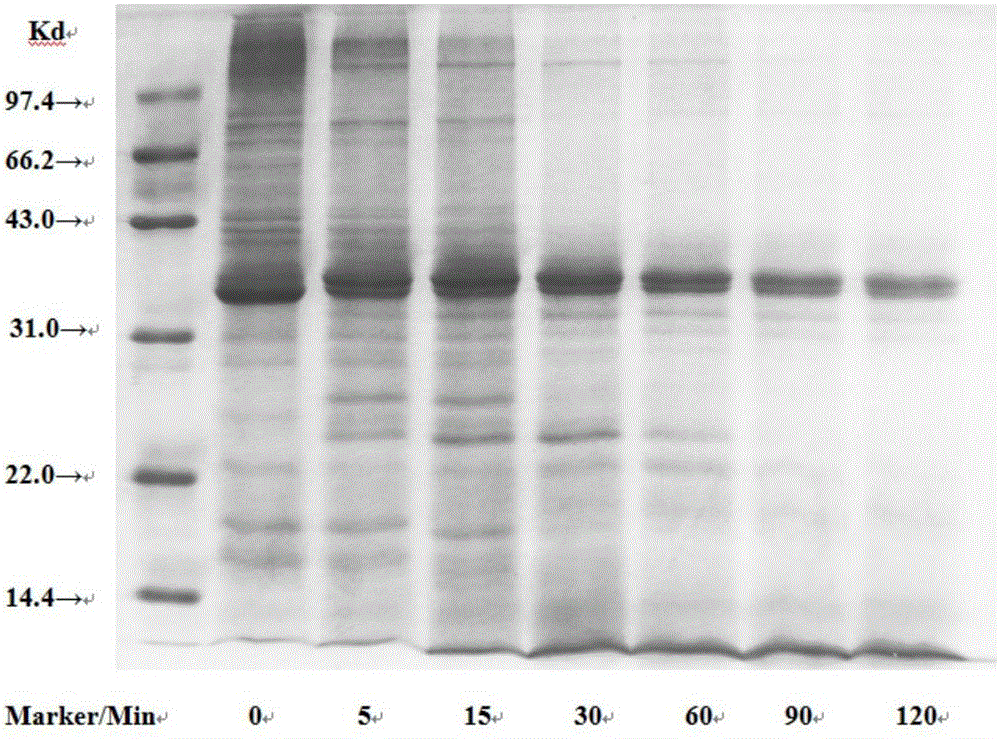

[0070] Figure 5 ~ Figure 8 Table 3 shows the SDS-PAGE electrophoresis images of hairtail proteins treated with unprocessed, steamed, boiled, and roasted in vitro simulated gastric juice for different periods of time.

[0071] Table 3 Comparison of protein bands in hairtail treatments

[0072]

[0073] From Table 3, we can conclude that based on the enzymolysis resistance of allergens, there is little difference between the three processing methods of steaming, boiling and baking, although the three processing methods all make the hairtail protein obtain a certain degree. During degradation, protein bands were significantly reduced, especially for large molecular proteins, but some bands still existed after 2 hours of in vitro digestion test, indicating that its resistance to enzymatic hydrolysis was stable. Only from the analysis of the types of remaining protein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com