Hydrophilic lubricating polyurethane medical interventional catheter and manufacturing method thereof

An interventional catheter, water-based polyurethane technology, applied in the field of medical devices, can solve problems such as lack of chemical bond connection, unsatisfactory coating firmness, and combination of catheter base material and coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

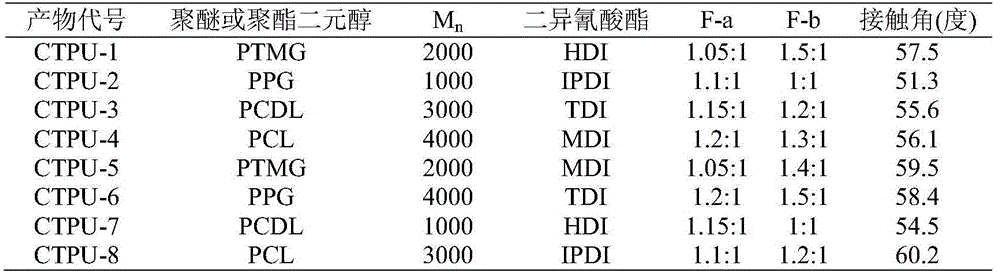

[0046] Preparation of carboxyl-containing thermoplastic polyurethane elastomer (CTPU):

[0047] Synthesize carboxyl-containing polyurethane elastomer by solvent method, add polyether or polyester diol and diisocyanate into the reactor, heat up to 80°C, stir and react for 2 hours to obtain prepolymer, add 2,2-dimethylol Propionic acid and 1,4-butanediol, reacted for 30 minutes, added N,N-dimethylformamide, continued to react for 1 hour, added dibutyltin dilaurate, reacted for another 6 hours, and cooled to room temperature, Pour the solution in the reactor into a container with deionized water, and a white precipitate precipitated out. The precipitate was collected and washed 3 times with deionized water, placed in a vacuum drying oven, and dried in vacuum at 110°C for 48 hours to obtain It is a transparent block product, which is pelletized to obtain a carboxyl group-containing polyurethane elastomer masterbatch.

[0048] Wherein, described polyether or polyester diol is sele...

Embodiment 2

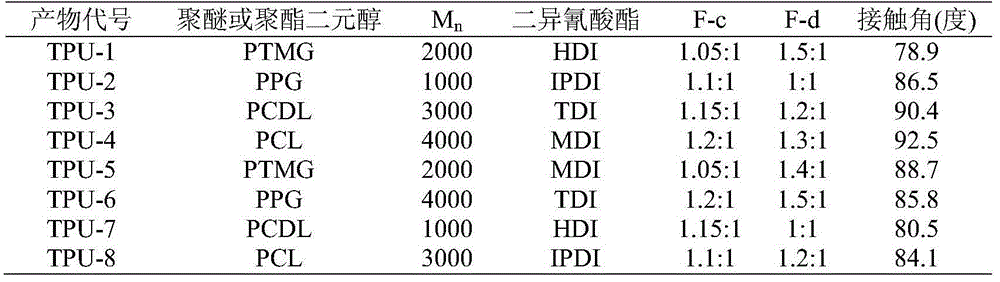

[0054] Preparation of carboxyl-free thermoplastic polyurethane elastomer (TPU):

[0055] Polyurethane elastomer without carboxyl groups is synthesized by melting method, polyether or polyester diol and diisocyanate are added into the reactor, the temperature is raised to 80°C, and the prepolymer is obtained after stirring for 2 hours, and 1,4-butanediol is added , after stirring for 5 minutes, pour the liquid in the reactor into the tray, place the tray in a vacuum drying oven, depressurize and pump air at room temperature until there is no foaming in the liquid, and then place it in a vacuum drying oven under normal pressure After curing at 110° C. for 24 hours, the bulk product was taken out from the tray and pelletized to obtain a carboxyl-free polyurethane elastomer masterbatch.

[0056] Wherein, described polyether or polyester diol is selected from polyoxypropylene diol (PPG), polytetrahydrofuran diol (PTMG), polycarbonate diol (PCDL), polycaprolactone diol (PCL) One of...

Embodiment 3

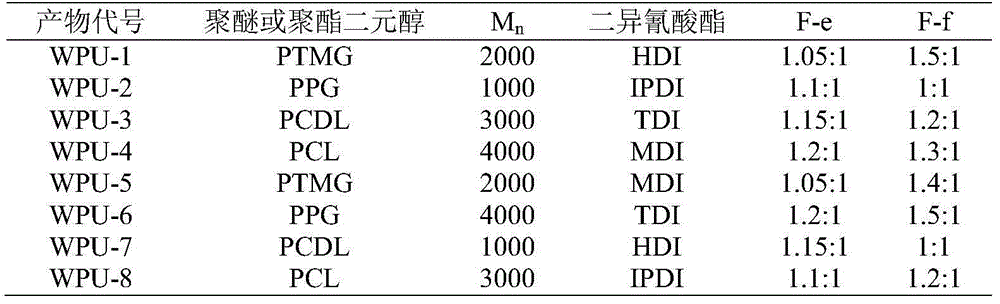

[0062] Preparation of water-based polyurethane emulsion (WPU):

[0063] Add polyether or polyester diol and diisocyanate into the reactor, raise the temperature to 80°C, stir and react for 2 hours to obtain a prepolymer, add 2,2-dimethylol propionic acid and 1,4-butanediol , after 30 minutes of reaction, the temperature dropped to 60°C, added acetone, continued to react for 1 hour, added dibutyltin dilaurate, reacted for another 6 hours, lowered to room temperature, added triethylamine, stirred for 10 minutes, added deionized water, use a high-speed mixer to emulsify the product for 10 minutes at a stirring speed of 8000 rad / min, and distill off the acetone in the product by vacuum distillation to obtain a water-based polyurethane emulsion.

[0064] Wherein, described polyether or polyester diol is selected from polyoxypropylene diol (PPG), polytetrahydrofuran diol (PTMG), polycarbonate diol (PCDL), polycaprolactone diol (PCL) One of the number average molecular weight (M n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com