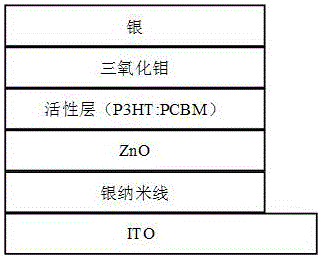

Inverted polymer solar cell with silver nanowire/ZnO laminated layer as electronic collection layer and manufacturing method thereof

An electron collection layer and silver nanowire technology, which is applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems of device overall performance degradation, poor chemical stability, etc., achieve low surface roughness, and enhance absorption capacity , solve the effect of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

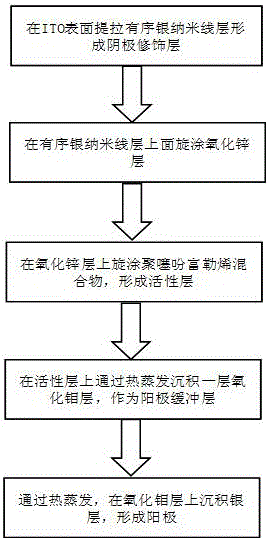

Method used

Image

Examples

Embodiment 1

[0032] (1) 20 mg polythiophene and 16 mg fullerene were weighed and dissolved in 1 ml dichlorobenzene according to a mass ratio of 1:0.8, and 20 ul DIO was added. The dissolution process was carried out in a nitrogen-filled glove box , put the solution on a hot stage at 50°C and stir for 12 hours;

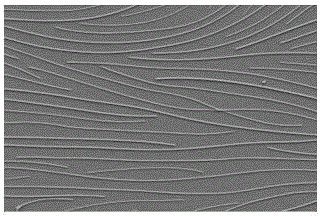

[0033] (2) Disperse silver nano-solutions with a mass fraction of 0.1% corresponding to silver nanowires with a diameter of 30 nm in isopropanol, the volume ratio of silver nano-solutions to isopropanol is 1:7, and filter with a microporous membrane Carrying out vacuum filtration to obtain a silver nanowire dispersion that is uniformly dispersed and has no obvious agglomeration;

[0034] (3) Carry out the following steps to clean the glass substrate in sequence: ultrasonication of acetone for 10 minutes, ultrasonication of deionized water for 10 minutes, ultrasonication of isopropanol for 10 minutes, and dry before use;

[0035] (4) Using the water bath method, heat 45ml of ultrap...

Embodiment 2

[0043](1) 20 mg polythiophene and 20 mg fullerene were weighed and dissolved in 1 ml dichlorobenzene according to the mass ratio of 1:1, and 20 ul DIO was added. The dissolution process was carried out in a glove box filled with nitrogen, The solution was placed on a hot stage at 50°C with stirring and heating for 12 hours;

[0044] (2) Disperse the silver nano-solution with a mass fraction of 0.1% corresponding to silver nanowires with a diameter of 60 nm in isopropanol, the volume ratio of silver nano-solution and isopropanol is 1:7, and filter with a microporous membrane Carrying out vacuum filtration to obtain a silver nanowire dispersion that is uniformly dispersed and has no obvious agglomeration;

[0045] (3) Carry out the following steps to clean the glass substrate in sequence: ultrasonication of acetone for 10 minutes, ultrasonication of deionized water for 10 minutes, ultrasonication of isopropanol for 10 minutes, and dry before use;

[0046] (4) Using the water ba...

Embodiment 3

[0053] (1) 24 mg polythiophene and 20 mg fullerene were weighed and dissolved in 1 ml dichlorobenzene according to a mass ratio of 1.2:1, and 20 ul DIO was added. The dissolution process was carried out in a nitrogen-filled glove box. The solution was placed on a hot stage at 50°C with stirring and heating for 12 hours;

[0054] (2) Disperse the silver nano-solution with a mass fraction of 0.1% corresponding to silver nanowires with a diameter of 25 nm in isopropanol, the volume ratio of silver nano-solution and isopropanol is 1:7, and filter with a microporous membrane Carrying out vacuum filtration to obtain a silver nanowire dispersion that is uniformly dispersed and has no obvious agglomeration;

[0055] (3) Carry out the following steps to clean the glass substrate in sequence: ultrasonication of acetone for 10 minutes, ultrasonication of deionized water for 10 minutes, ultrasonication of isopropanol for 10 minutes, and dry before use;

[0056] (4) Using the water bath m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com