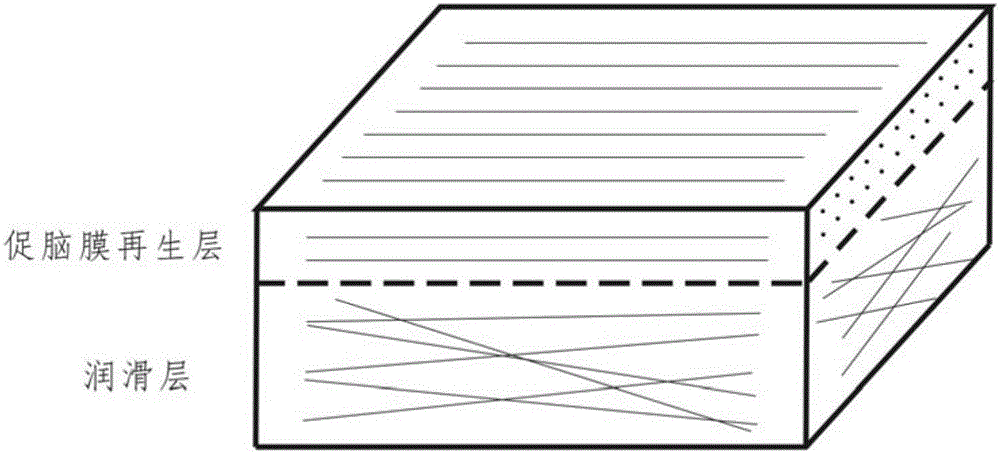

Bionical type absorbable dura mater patch and preparation method and application thereof

A dura mater and bionic technology, which is applied in the field of bionic absorbable dura mater patch and its preparation, can solve the problems of biomimetic and meningeal composition biomimetic, and achieve good biocompatibility, suture-free fixation, and novel structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Dissolve polylactic acid-glycolic acid copolymer with a weight average molecular weight of 120,000 in hexafluoroisopropanol at a concentration of 0.1 g / ml; dissolve sodium hyaluronate with a relative molecular weight of 1.2 million in deionized water at a concentration of 0.06 g / ml; a homogeneous and stable solution was formed after stirring separately at room temperature. After that, the two solutions were uniformly mixed under high-speed stirring, and the volume ratio was 95:5, which was the spinning solution a.

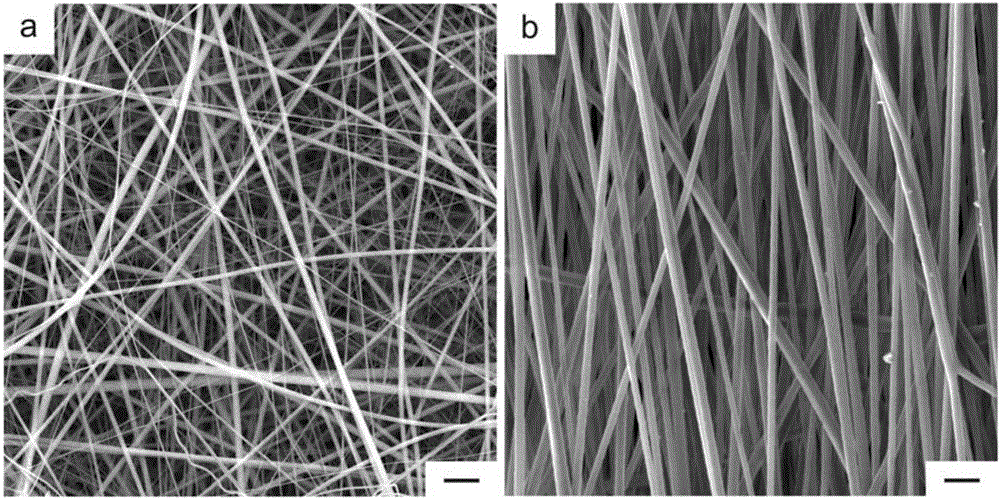

[0068] Put the mixed solution into a syringe, and connect the needle of the syringe to a high-voltage power supply. The solution supply flow rate was controlled at 3 ml / h, the applied voltage was 15 kV, the distance between the high-voltage end and the ground end was 15 cm, and a rotating drum with a diameter of 8 cm was used as a collection device at a speed of 100 rpm. After spinning for 5 hours, the lubricating layer fiber film ( figure 2 a).

[0069]...

Embodiment 2

[0073] Dissolve L-polylactic acid with a weight average molecular weight of 300,000 in dichloromethane at a concentration of 0.08 g / ml; dissolve carboxymethyl chitosan with a relative molecular weight of 200,000 in deionized water at a concentration of 0.02 g / ml . The two solutions were uniformly mixed under high-speed stirring, and the volume ratio was 95:5, which was the spinning solution a.

[0074] The solution supply flow rate was controlled at 1 ml / hour, the applied voltage was 12.5 kV, the distance between the high-voltage end and the ground end was 10 cm, and a rotating drum with a diameter of 8 cm was used as a collection device at a speed of 100 rpm. After spinning for 6 hours, a lubricating layer fiber film with a thickness of about 0.15 mm and disorderly arrangement can be collected.

[0075] The L-polylactic acid with a weight average molecular weight of 300,000 and the polyethylene glycol with a weight average molecular weight of 10,000 are dissolved in methylen...

Embodiment 3

[0079] The polylactic acid-caprolactone copolymer that weight-average molecular weight is 300,000 is dissolved in the mixed solution (volume ratio is 4:1) of dimethylformamide and tetrahydrofuran, and concentration is 0.12 g / ml; Sulfate sodium was dissolved in deionized water at a concentration of 0.01 g / ml. Finally, the two solutions are uniformly mixed under high-speed stirring, and the volume ratio is 97:3, which is the spinning solution a.

[0080] The solution supply flow rate was controlled at 1.5 ml / hour, the applied voltage was 15 kV, the distance between the high-voltage end and the ground end was 12.5 cm, and a rotating drum with a diameter of 8 cm was used as a collection device at a speed of 100 rpm. After 7 hours of spinning, the lubricating layer fiber film with a thickness of about 0.25 mm and disorderly arrangement can be collected.

[0081] The polylactic acid-caprolactone copolymer with a weight average molecular weight of 300,000 and the carbomer with a wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com