Clean water and method for preparing same

A technology of clean water and electrolyzed water, which is applied in the field of detergent, can solve the problems that chemical detergent increases the difficulty of wastewater treatment, permeability, insufficient activity, and secondary pollution of the human body, etc., to achieve good moisturizing and protective effects, penetration The effect of strong sex and activity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

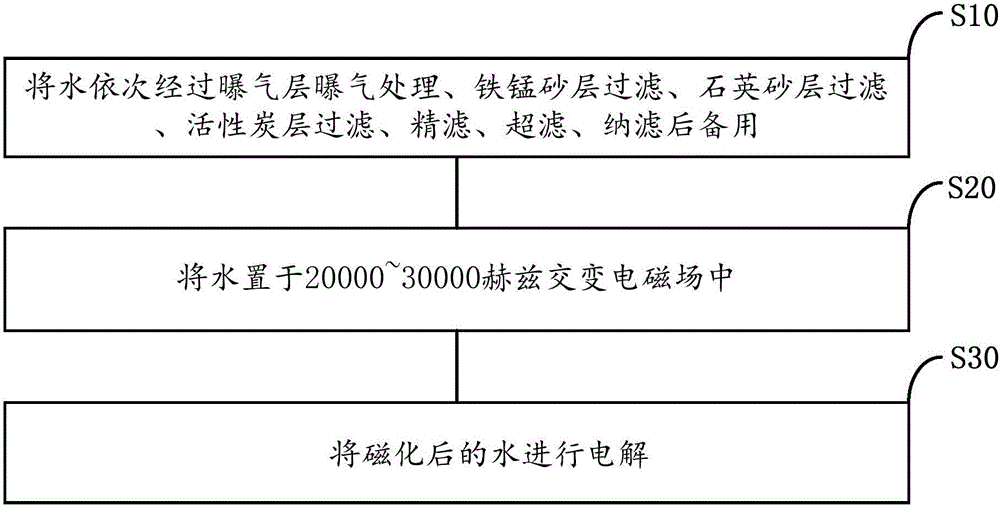

[0037] see figure 1 , the invention provides a kind of preparation method of clean water, comprises the following steps:

[0038] The corresponding content of step S10 is that the water is sequentially passed through the aeration layer aeration treatment, ferromanganese sand layer filtration, quartz sand layer filtration, activated carbon layer filtration, fine filtration, ultrafiltration, nanofiltration, and backup;

[0039] The corresponding content of step S20 is that the water prepared in step S10 is placed in a water container provided with a magnetized metal part, and then placed in an alternating electromagnetic field of 20000-30000 Hz generated by an electromagnetic coil, and the magnetized metal part is Under the alternating electromagnetic field of 20000-30000 Hz, the metal induction eddy current effect heats up, and the water in the water container is heated. At the same time, the alternating electromagnetic field of 20000-30000 Hz directly magnetizes the water, and...

Embodiment 1

[0062] S10: The water is sequentially aerated through the aeration layer filled with spherical ceramsite with a particle size of 2mm, filtered with a 10cm-thick iron-manganese sand layer, 10cm-thick quartz sand layer, 10cm-thick activated carbon layer, fine filter , ultrafiltration and nanofiltration for later use;

[0063] S20: The water prepared in step S10 is placed in a water container provided with a magnetic metal part, and then placed in a 20000 Hz alternating electromagnetic field generated by an electromagnetic coil, and the magnetic metal part is generated under a 20000 Hz alternating electromagnetic field The metal-induced eddy current effect heats up, heating the water in the water container, and at the same time, the 20,000 Hz alternating electromagnetic field directly magnetizes the water, and the magnetized water induces a 20,000 Hz positive and negative sine wave in the alternating electromagnetic field, which is Water is subjected to high-frequency magnetic ro...

Embodiment 2

[0066] S10: The water is sequentially aerated through the aeration layer filled with spherical ceramsite with a particle size of 4mm, filtered by a 30cm-thick iron-manganese sand layer, filtered by a 30cm-thick quartz sand layer, filtered by a 30cm-thick activated carbon layer, and finely filtered , ultrafiltration and nanofiltration for later use;

[0067] S20: The water prepared in step S10 is placed in a water container provided with a magnetic metal part, and then placed in a 30000 Hz alternating electromagnetic field generated by an electromagnetic coil, and the magnetic metal part is generated under a 30000 Hz alternating electromagnetic field. The metal-induced eddy current effect heats up, heating the water in the water container, and at the same time, the 30,000 Hz alternating electromagnetic field directly magnetizes the water, and the magnetized water induces a 30,000 Hz positive and negative sine wave in the alternating electromagnetic field, which is Water is subj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com