Production method of arginine active peptide powder for livestock and poultry

A production method and technology of arginine, which is applied in the field of arginine fermentation technology and microbial solid fermentation, can solve the problems of Yin Yulong, lack of quality and safety brands, and lack of brands in the embryonic stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

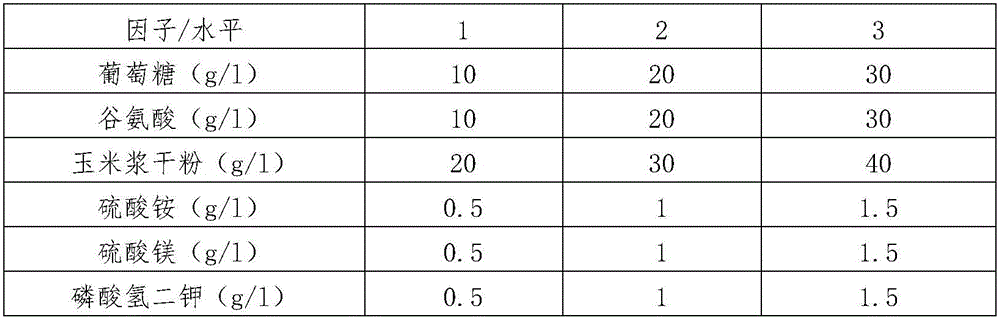

[0043] (1) Preparation of arginine concentrated bacterial liquid wet powder: Inoculate the arginine-producing bacteria strain into the arginine-producing bacteria fermenter seed medium, and the arginine-producing bacteria fermenter seed medium is expressed in weight percentage It is: 2.0% of glucose, 2.0% of glutamic acid, 3.0% of corn steep liquor dry powder, 0.1% of ammonium sulfate, 0.1% of magnesium sulfate, 0.1% of dipotassium hydrogen phosphate, the balance is water, and the inoculum size is 10%. After 48 hours of cultivation, the number of viable bacteria containing arginine-producing bacteria is obtained ≥ 10 billion / ml seed solution.

[0044] Concentration process and reaction conditions of arginine concentrated bacterial liquid wet powder. First, put 4 tons of arginine fermentation liquid into a 5-ton reaction kettle, start stirring, add flocculant at 0.1% to 0.4%, and use sulfuric acid to Adjust the pH value of the arginine fermentation liquid to 5.0-6.5, react at a...

Embodiment 1

[0108] Concentration process and confirmation of reaction conditions of arginine concentrated bacterial liquid wet powder

[0109] Pour 4 tons of arginine fermentation broth into a 5-ton reactor, start stirring, add flocculants (both produced by Aisen China Flocculant Co., Ltd.) at 0.1% to 0.4%, and ferment the arginine with sulfuric acid Adjust the pH value of the liquid to 5.0-6.5, react at a temperature of 40°C-55°C, and the reaction time is 50-80 minutes, and then press it into the filter press with a pressure of 3mpa, and the filter press time is 20-50 minutes. The arginine concentrated bacterial liquid wet powder with a water content of 20% to 30% is obtained.

[0110] Concentration process and condition test of arginine concentrated bacterial liquid wet powder

[0111] The experimental design is 5 factors and 4 levels. The experimental design and experimental results are shown in Table 1:

[0112] Table 1. Concentration and reaction condition test of arginine concentr...

Embodiment 2

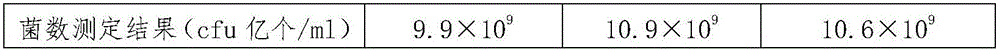

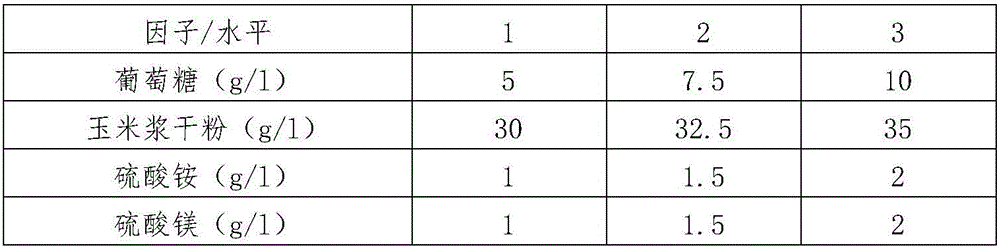

[0116] Formulation of Arginine-producing Bacteria Fermenter Seed Medium Formula and Confirmation of Fermentation Conditions

[0117] The arginine-producing bacteria are Brevibacterium flavums. The main features are: 1. Using glutamic acid as the fermentation substrate, the nutritional requirements are high carbon and high nitrogen, and can successfully metabolize L-arginine 2. Nitrogen and carbon are added during the fermentation process to synthesize arginine and peptide substances, so as to obtain a fermentation broth with a higher arginine content. Arginine-producing bacteria also have the characteristics of fast reproduction speed, good stability, and wide application range.

[0118] The specific operation steps of single colony purification and optimization, solid eggplant-shaped flat bottle seed cultivation, and fermenter submerged fermentation seed cultivation are as follows:

[0119] Single colony purification: see (7) 1) of raw material preparation step;

[0120] So...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com