Anti-irradiation solar energy cell manufacturing method

A solar cell and anti-irradiation technology, which is applied in the field of solar cells, can solve problems such as falling off, reducing the absorption efficiency of the cell, and affecting the photoelectric conversion efficiency of the cell, and achieves the effects of good thermal shock resistance, stable charging performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

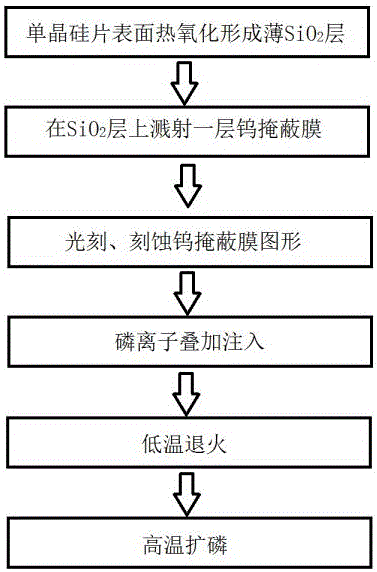

[0011] Such as figure 1 Shown, the inventive method comprises the following steps:

[0012] Step 1: Use a P-type single crystal silicon wafer with a resistivity of 6-8Ω.cm, and thermally oxidize the surface to form a SiO with a thickness of 35nm 2 Floor;

[0013] Step 2: On SiO 2 A layer of tungsten masking film is sputtered on the layer;

[0014] Step 3: Form a tungsten masking film pattern by photolithography and etching, so that the line width of the implanted area of the pattern is 2 μm, and the masking interval width is 3 μm;

[0015] Step 4: Perform superposition implantation of phosphorus ions on the tungsten masking film, the number of times is five, and the energy and dose of each implantation are respectively 0.4MeV, 3×10 14 / cm 2 ;0.7MeV, 3×10 13 / cm 2 ; 1.2MeV, 5×10 13 / cm 2 ;3MeV, 8×10 13 / cm 2 ;6 MeV, 1×10 14 / cm 2 ;

[0016] Step 5: Perform low-temperature annealing on the ion-implanted silicon wafer in a protective nitrogen environment at a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com