Starch-based super-absorbent resin environment friendly slow-release fertilizer and preparation method thereof

A super absorbent resin, environmentally friendly technology, applied in nitrogen fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of microbial degradation, resource waste, eutrophication, etc., to improve reaction efficiency, shorten reaction time, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

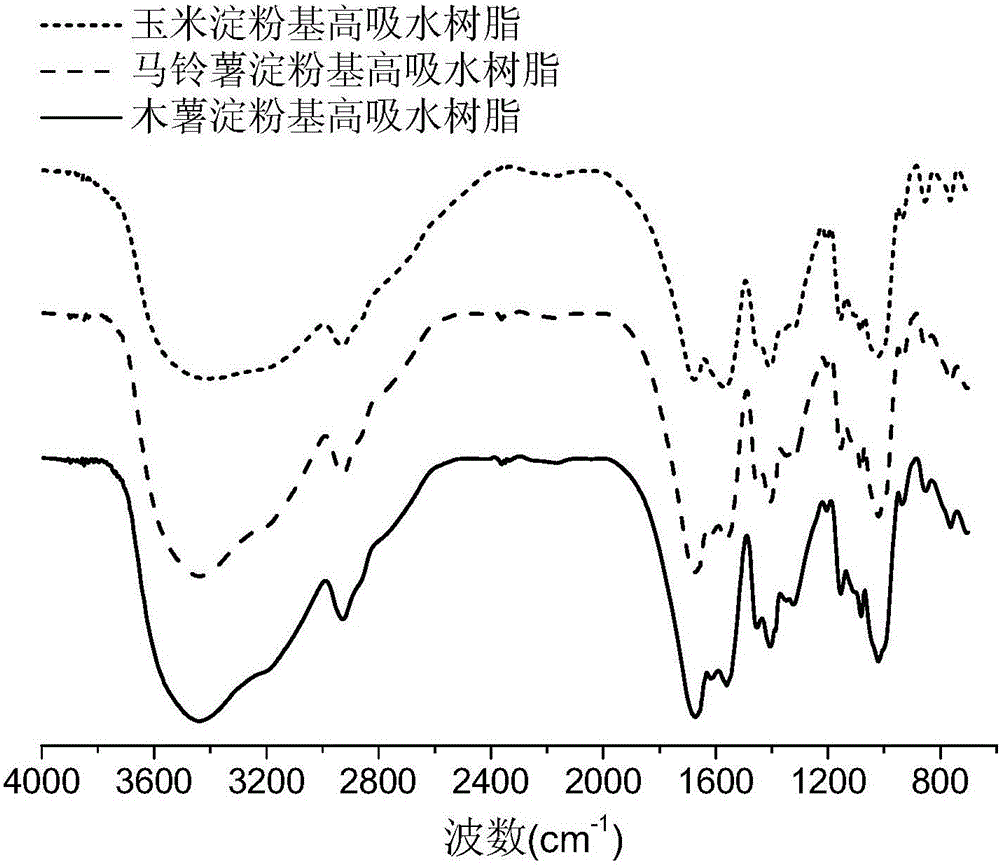

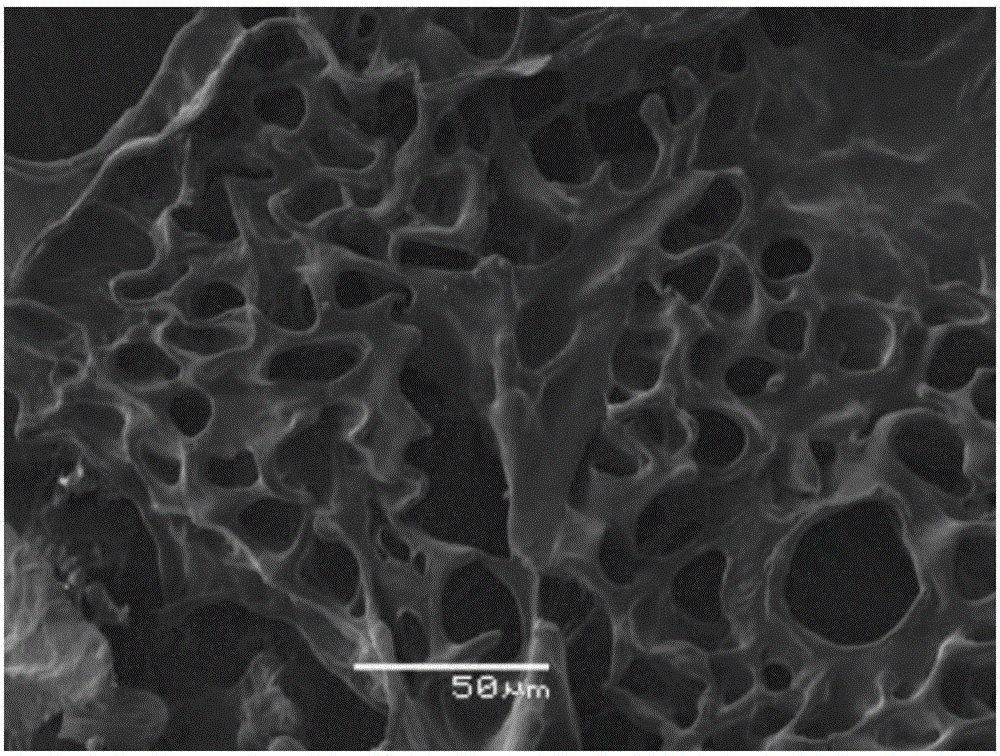

Embodiment 1

[0033] (1) Combine corn starch (moisture content 13.29%), boiling water, acrylamide, N, N-methylenebisacrylamide (mass ratio of corn starch: acrylamide: boiling water is 4:6:15 on a dry basis, N , the mass of N-methylenebisacrylamide is 0.47% of the sum of the mass of cornstarch and acrylamide on a dry basis) into a double-roller internal mixer at 80 °C, after mixing and banburying for 10 minutes (rotational speed 80 rpm) , lower the temperature to 60°C, then add ceric ammonium nitrate (the mass of ceric ammonium nitrate is 2.5% of the sum of the dry basis corn starch and acrylamide mass), then mix and banbury for 10 min (speed 80 rpm), and finally add hydrogen Sodium oxide (sodium hydroxide: acrylamide molar ratio is 1:1), after mixing and banburying for 10 min (speed 80 rpm), the crude product was obtained. After the crude product was soaked in tap water for 24 h, it was washed with tap water until pH = 7; then the product was placed in an air-dried oven at 80 °C to constant...

Embodiment 2

[0037] (1) Tapioca starch (moisture content 15.37%), boiling water, acrylamide, N, N-methylenebisacrylamide (the mass ratio of tapioca starch: acrylamide: boiling water on a dry basis is 4:6:15, N , the mass of N-methylenebisacrylamide is 0.47% of the sum of the mass of starch and acrylamide) into the double-roller internal mixer at 80 °C, after mixing and banburying for 10 minutes (speed 80rpm), cool down to 60 °C, then add ceric ammonium nitrate (the mass of ceric ammonium nitrate is 2.5% of the sum of the mass of dry base tapioca starch and acrylamide), mix and banbury for 10 min (speed 80 rpm), and finally add sodium hydroxide (hydrogen Sodium oxide: acrylamide molar ratio is 1:1), after mixing and banburying for 10 min (rotating speed 80 rpm), the crude product was obtained. After the crude product was soaked in tap water for 24 h, it was washed with tap water to pH = 7; then the product was placed in an air-dried oven at 80 °C to constant weight; it was ground again and ...

Embodiment 3

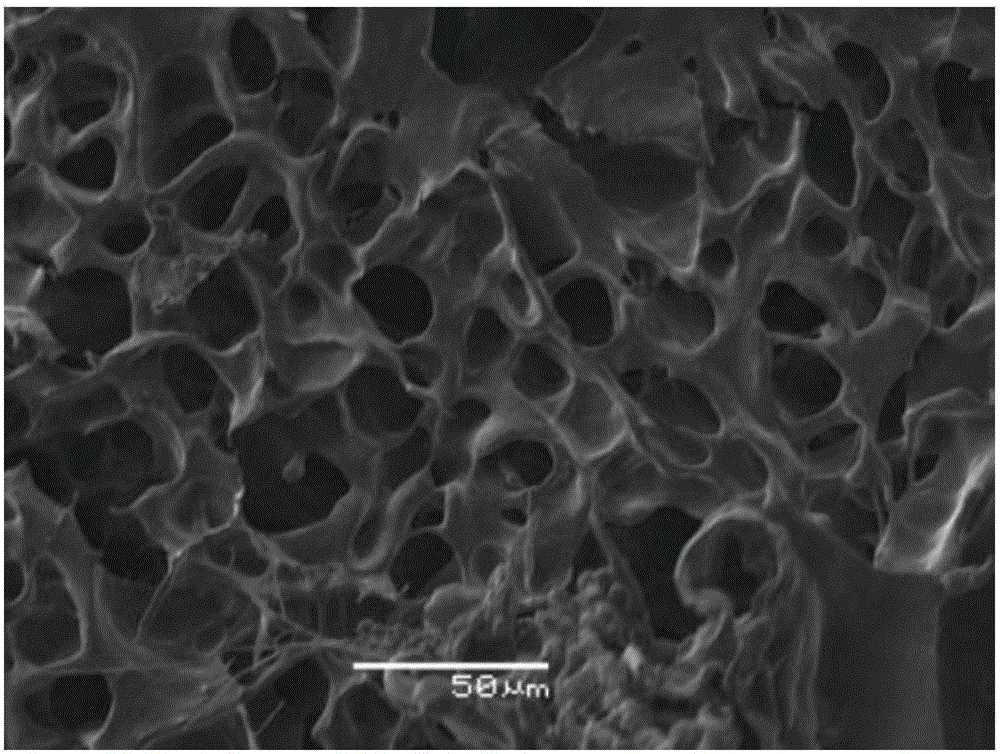

[0041] (1) Potato starch (moisture content 15.84%), boiling water, acrylamide, N, N-methylenebisacrylamide (mass ratio of potato starch: acrylamide: boiling water on a dry basis is 4:6:15, N , the mass of N-methylenebisacrylamide is 0.47% of the sum of the mass of starch and acrylamide) into the double-roller internal mixer at 80 °C, after mixing and banburying for 10 minutes (speed 80rpm), cool down to 60 °C, then add ceric ammonium nitrate (the mass of ceric ammonium nitrate is 2.5% of the sum of the mass of starch and acrylamide), mix and banbury for 10 min (speed 80 rpm), and finally add sodium hydroxide (sodium hydroxide: The molar ratio of acrylamide is 1:1), and the crude product was obtained after mixing and banburying for 10 min (rotating speed 80 rpm). After the crude product was soaked in tap water for 24 h, it was washed with tap water to pH = 7; then the product was placed in an air-dried oven at 80 °C to constant weight; it was ground again and passed through a 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com