Flotation separation method for copper in waste mobile phone circuit board

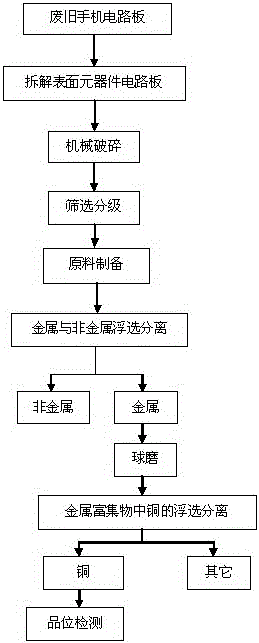

A separation method and circuit board technology, applied in flotation, solid separation, solid waste removal, etc., can solve the problems of unsatisfactory metal separation effect and inability to separate, and achieve low cost, low secondary pollution, and recycling. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Remove the surface components of the waste circuit board, crush and sieve the mobile phone circuit board with the surface components removed to obtain a crushed product with a particle size of 0.45-0.30mm; moisten the crushed product with a particle size of 0.30-0.45mm with absolute ethanol to prevent agglomeration, and then Make a slurry with a concentration of 100g / L, and use a flotation machine to go through one roughing, two refining and one sweeping without adding any flotation agent, and separate the metal enrichment. Operating conditions: rotation speed 2000rpm, gas filling rate 100L / h; the obtained metal enrichment is classified first, and metal flotation materials in 4 different particle size ranges are obtained: 0.3mm~0.15mm, 0.15mm~0.125mm, 0.125mm~0.074 mm, -0.074mm, ball mill the metal concentrates of the first three particle sizes to a particle size of 0.074mm and below; the obtained metal concentrates with a particle size of 0.074mm and below are subjected...

Embodiment 2

[0026] Remove the surface components of waste circuit boards, and crush the mobile phone circuit boards from which the surface components have been removed to a particle size of 0.45 mm or below; wet the obtained circuit board crushed products with a particle size of 0.45 mm or below to prevent agglomeration, and prepare a concentration of 150g / L slurry, at room temperature, the amount of No. 2 oil added is 150g / t, using a flotation machine to go through 1 roughing, 3 refining and 1 sweeping to obtain metal enrichment, of which flotation The operating conditions of the machine are: rotating speed 2200rpm, gas filling rate 120L / h; direct ball milling of the obtained metal enrichment to a particle size of 0.15mm and below; manual magnetic separation of the metal enrichment obtained by ball milling with a particle size of 0.15mm and below , and then wet with absolute ethanol to prevent agglomeration, and make a slurry with a concentration of 100g / L, the addition of sodium sulfide ...

Embodiment 3

[0028]Disassemble the used mobile phone to obtain the circuit board, and then remove the surface components of the obtained circuit board, and crush the mobile phone circuit board with the removed surface components to a particle size of 0.45mm or below; the crushed circuit board with a particle size of 0.45mm or below The crushed product is wetted with ethylene glycol to prevent agglomeration, and the pulp concentration is made into a solution of 100g / L. Secondary sweeping and separation to obtain metal enrichment, the operating conditions of the flotation machine are: rotating speed 2500rpm, gas filling rate 80L / h; the obtained metal enrichment is directly ball milled to a particle size of 0.074mm or below; the particle size obtained by ball milling The metal enrichment of 0.074mm and below is subjected to manual magnetic separation, then wetted with ethylene glycol to prevent agglomeration, and made into a pulp solution with a concentration of 100g / L. At room temperature, 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com