Preparing method for BiVO4 nnanobelt material

A nanobelt, 3·5H2O technology, applied in the field of nanofibers, can solve problems such as difficulty in realizing fine control, and achieve the effect of simple and controllable preparation method and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

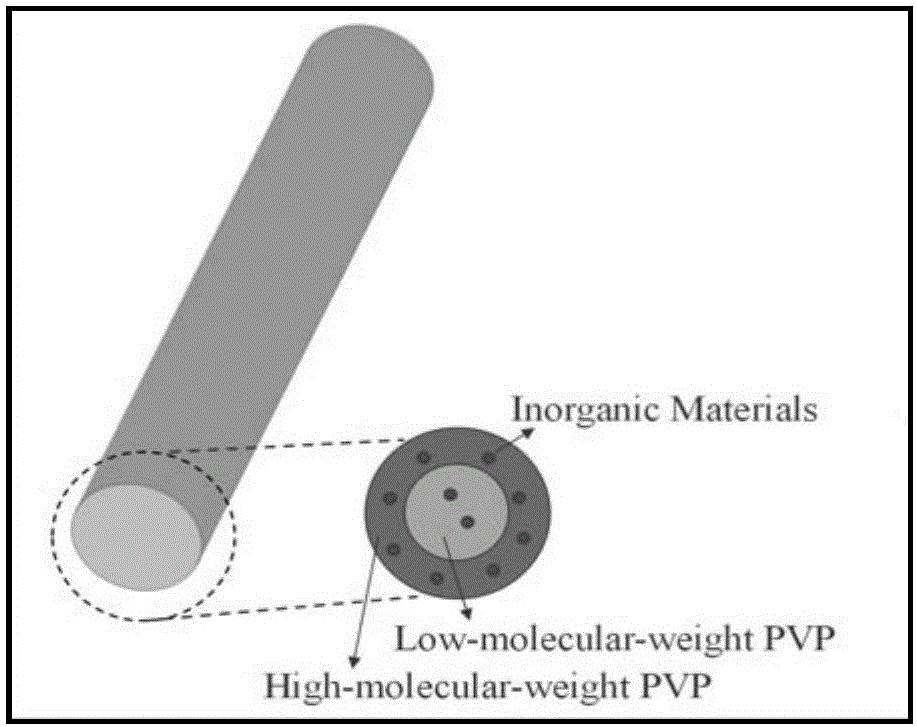

[0046] Weigh polyvinylpyrrolidone (PVP K90 ) 0.4g, polyvinylpyrrolidone (PVP K30 )0.4g, bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) 1.21g and acetylacetonoxane (VO(acac) 2 ) 0.662g was dissolved in a mixture of 2.5g absolute ethanol, N-N dimethylformamide (DMF) 2.5g and 2g glacial acetic acid, stirred and mixed at room temperature for 6 hours to obtain a dark green transparent solution. After the microemulsion to be spun was left to stand, 6ml was measured and injected into a plastic needle tube, and placed on a micro-injection pump, and the injection speed was set at 0.2mm / min. The metal needle was used as the electrospinning anode, and the barbed wire was used as the cathode of the receiving material. The distance between the anode and the cathode was 20 cm. Electrospinning was performed at a high voltage of 12kV to prepare organic precursor fiber materials. Then, the organic precursor fiber material was placed in a constant temperature oven at 80° C. to obtain a...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is that the polyvinylpyrrolidone (PVP) added in this embodiment K30 ) is 1.2g, and the others are the same as in Example 1, and the precursor spinning liquid is configured first, and then electrospun to obtain solid precursor fibers, and finally processed by calcination to obtain BiVO 4 nanomaterials. No more detailed description here.

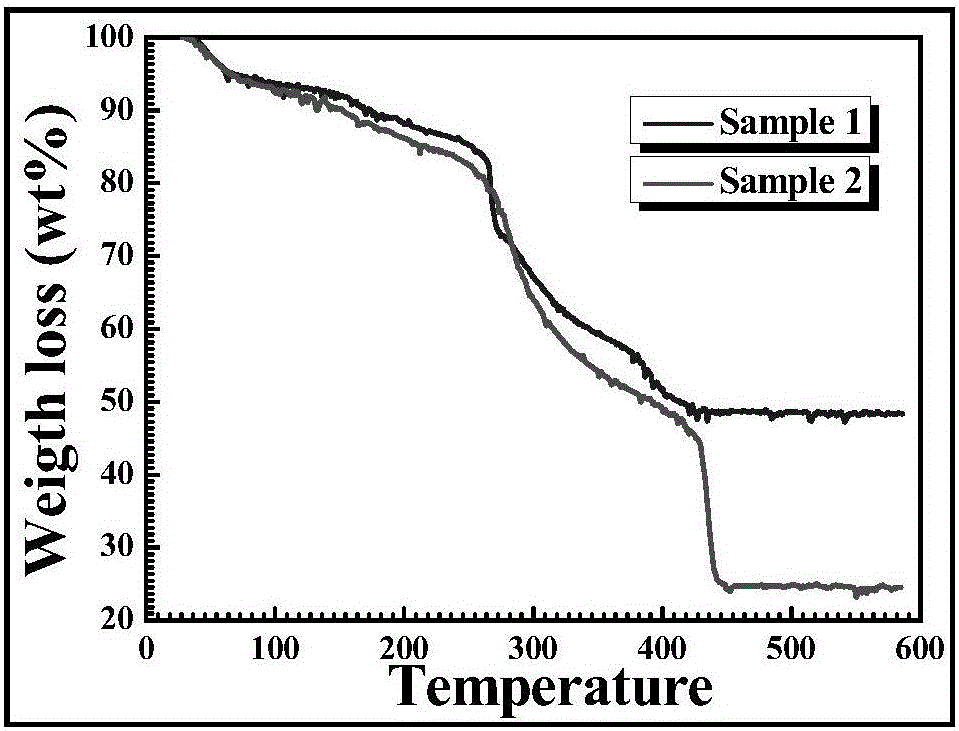

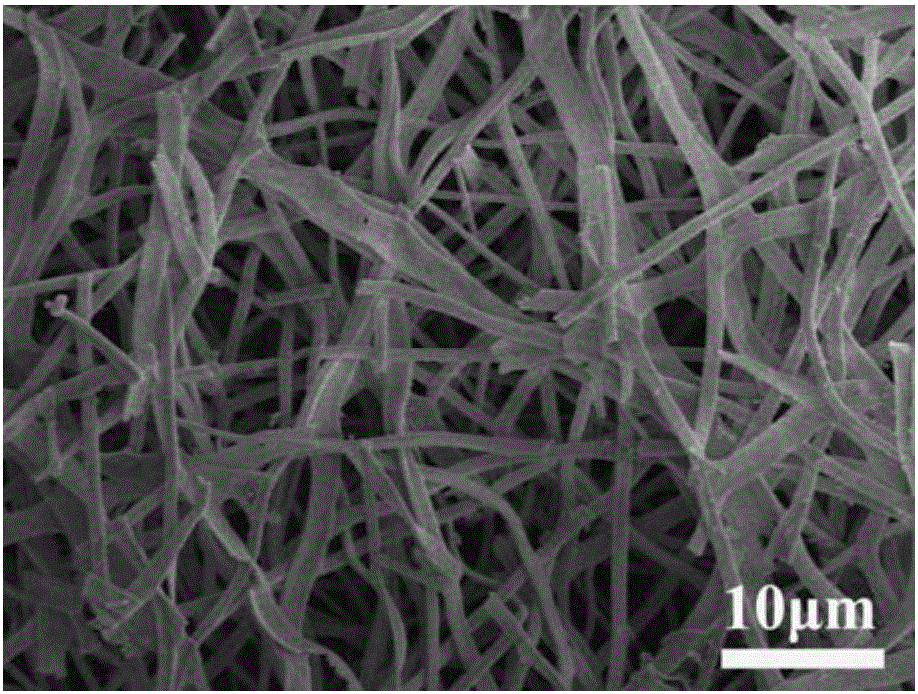

[0050] BiVO 4 Low magnification scanning electron microscope (SEM) and high magnification scanning electron microscope (SEM) of the precursor fibers of nanomaterials such as Figure 5 and Figure 6 , indicating that the prepared material is a nanofiber. The final BiVO 4 Low magnification scanning electron microscope (SEM) and high magnification scanning electron microscope (SEM) of nanomaterials such as Figure 7 and Figure 8 , indicating that the final synthesized material has a typical nanoribbon structure. BiVO 4 The corresponding X-ray diffraction spectrum of the nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com