A kind of inorganic thermal insulation material and its preparation method and application

A technology of inorganic thermal insulation materials and raw materials, applied in the field of thermal insulation materials, can solve the problems of large capacity of thermal insulation materials, difficulty in performing thermal insulation, high thermal conductivity, etc., to reduce dry bulk density and thermal conductivity, increase strength and toughness, improve The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

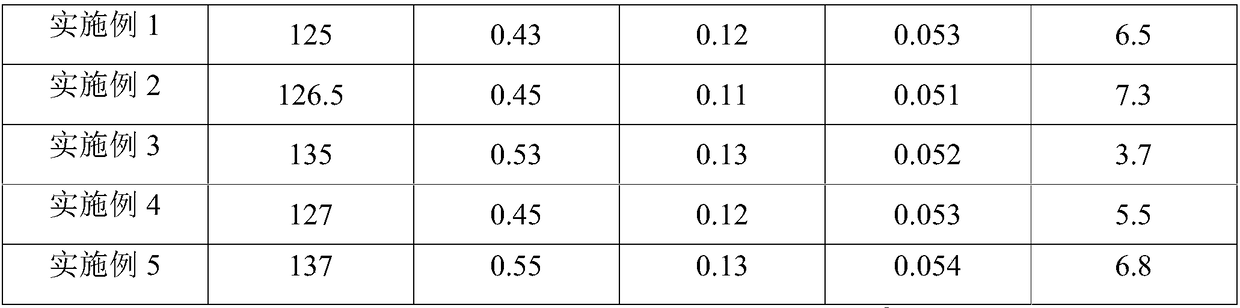

Embodiment 1

[0028] An inorganic thermal insulation material, comprising the following raw materials in parts by weight: 70 parts of ordinary Portland cement grade 42.5, 30 parts of slag powder, 2 parts of pretreated nano-silica, 2 parts of polymer prepolymer, polycarboxylic acid water-reducing 0.5 parts of agent, 1 part of polypropylene fiber, 6 parts of 27.5% hydrogen peroxide aqueous solution, and 43 parts of water.

[0029] The slag powder is S95 grade (conforming to "GB / T 18046-2008 Granulated Blast Furnace Slag Powder Used in Cement and Concrete").

[0030] The raw material and weight ratio of pretreatment nano-silica are nano-silica: silane coupling agent: dehydrated alcohol=80:4:4, nano-silica is fumed silica A150, and silane coupling agent is Aminopropyltriethoxysilane.

[0031] The raw material of the polymer prepolymer and its weight ratio are epoxy resin: acrylic acid: catalyst: curing agent: silane coupling agent = 40:25:4:6:2, the catalyst in this embodiment is a tertiary am...

Embodiment 2

[0039] An inorganic thermal insulation material, comprising the following raw materials in parts by weight: 70 parts of ordinary Portland cement grade 52.5, 30 parts of fly ash, 3.5 parts of pretreated nano-silicon dioxide, 1.5 parts of polymer prepolymer, polycarboxylic acid reducing 0.7 parts of water agent, 0.6 parts of basalt fiber, 9 parts of 27.5% hydrogen peroxide aqueous solution, and 38 parts of water.

[0040]Fly ash is a first-class fly ash (in accordance with "GB1596-2005 for fly ash in cement and concrete").

[0041] The raw material and its weight ratio of pretreatment nano-silica are nano-silica: silane coupling agent: dehydrated alcohol=90:15:15, and nano-silica is fumed silica A250 and precipitated silica Grade C mixture, the silane coupling agent is glycidyl etheroxypropyl trimethoxysilane.

[0042] The raw material of polymer prepolymer and its weight ratio are epoxy resin: acrylic acid: catalyst: curing agent: silane coupling agent = 40: 27: 2: 7.2: 1.5. I...

Embodiment 3

[0050] An inorganic thermal insulation material, comprising the following raw materials in parts by weight: 65 parts of a mixture of ordinary Portland cement grade 42.5 and grade 52.5, 35 parts of fly ash, 5 parts of pretreated nano-silica, and 4 parts of polymer prepolymer , 1 part of polycarboxylate superplasticizer, 0.7 parts of a mixture of polypropylene fiber and basalt fiber, 9.5 parts of 27.5% hydrogen peroxide aqueous solution, and 41 parts of water.

[0051] Fly ash is a first-class fly ash (in accordance with "GB1596-2005 for fly ash in cement and concrete").

[0052] The raw material and weight ratio of pretreatment nano-silica is nano-silica: silane coupling agent: absolute ethanol = 120:7:7, nano-silica is precipitated white carbon black grade B, silane coupling agent It is γ-methacryloxypropyltrimethoxysilane.

[0053] The raw material of polymer prepolymer and its weight ratio are epoxy resin: acrylic acid: catalyst: curing agent: silane coupling agent = 50: 40...

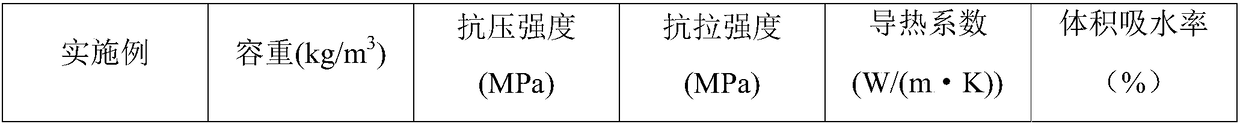

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com