Protective pipe for underground laying of communication cables

A technology for communication cables and protection tubes, which is applied in the field of laying protection tubes underground for communication cables, which can solve problems such as communication quality degradation, long communication distances, and easy damage, and achieve improved anti-aging performance and performance, and good corrosion resistance , good comprehensive performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

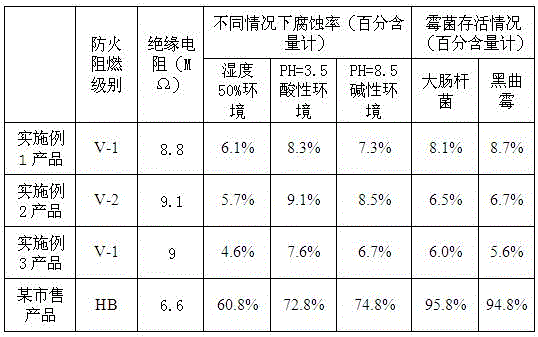

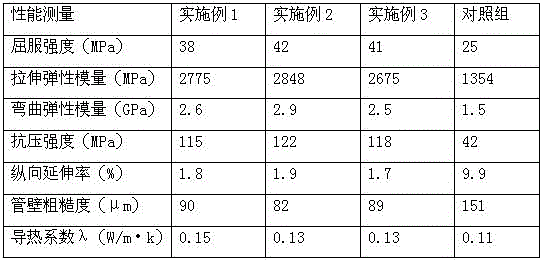

Embodiment 1

[0017] The protective pipe for underground laying of communication cables in this embodiment consists of the following components in parts by mass: 14 parts of hexamethylphosphoric triamide, 16 parts of triethanolamine borate, 12 parts of zirconia powder, polycarbonate 10 parts, 16 parts of vinyl acetate, 12 parts of tribasic lead sulfate, 10 parts of ketoconazole, 16 parts of sodium dichloroisocyanurate, 12 parts of isothiazolinone, 10 parts of tea polyphenols, sodium lauryl sulfate 16 parts, 12 parts of diethylene glycol butyl ether, 12 parts of sodium molybdate, 10 parts of didecyl dimethyl ammonium chloride, 16 parts of polyhexamethylene guanidine, 12 parts of sorbic acid, 10 parts of sodium diacetate, phenolic 16 parts of resin, 12 parts of ester glue varnish, 10 parts of kaolin, 16 parts of talcum powder, 12 parts of aluminum hydroxide powder, 10 parts of montmorillonite, 16 parts of vinyl acetate, 12 parts of nano zinc oxide, 12 parts of aniline, fluorescent powder 12 p...

Embodiment 2

[0024]The protective pipe for underground laying of communication cables in this embodiment consists of the following components in parts by mass: 16 parts of hexamethylphosphoric triamide, 18 parts of triethanolamine borate, 14 parts of zirconia powder, polycarbonate 12 parts, 18 parts of vinyl acetate, 14 parts of tribasic lead sulfate, 12 parts of ketoconazole, 18 parts of sodium dichloroisocyanurate, 14 parts of isothiazolinone, 12 parts of tea polyphenols, sodium lauryl sulfate 18 parts, 14 parts of diethylene glycol butyl ether, 14 parts of sodium molybdate, 12 parts of didecyl dimethyl ammonium chloride, 18 parts of polyhexamethylene guanidine, 14 parts of sorbic acid, 12 parts of sodium diacetate, phenolic 18 parts of resin, 14 parts of ester glue varnish, 12 parts of kaolin, 18 parts of talc powder, 14 parts of aluminum hydroxide powder, 12 parts of montmorillonite, 18 parts of vinyl acetate, 14 parts of nano zinc oxide, 14 parts of aniline, fluorescent powder 14 part...

Embodiment 3

[0031] The protection pipe for underground laying of communication cables in this embodiment consists of the following components in parts by mass: 18 parts of hexamethylphosphoric triamide, 20 parts of triethanolamine borate, 16 parts of zirconia powder, polycarbonate 14 parts, 20 parts of vinyl acetate, 16 parts of tribasic lead sulfate, 14 parts of ketoconazole, 20 parts of sodium dichloroisocyanurate, 16 parts of isothiazolinone, 14 parts of tea polyphenols, sodium lauryl sulfate 20 parts, 16 parts of diethylene glycol butyl ether, 16 parts of sodium molybdate, 14 parts of didecyldimethylammonium chloride, 20 parts of polyhexamethylene guanidine, 16 parts of sorbic acid, 14 parts of sodium diacetate, phenolic 20 parts of resin, 16 parts of ester glue varnish, 14 parts of kaolin, 20 parts of talcum powder, 16 parts of aluminum hydroxide powder, 14 parts of montmorillonite, 20 parts of vinyl acetate, 16 parts of nano zinc oxide, 16 parts of aniline, fluorescent powder 16 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com