Industrial production and detection method of excellent migration-resistant heat-resistant pigment red PR-48: 2

A heat-resistant performance and production method technology, applied in chemical instruments and methods, color/spectral characteristic measurement, azo dyes, etc., can solve problems such as inability to distinguish good or bad product migration, failure to perform characterization, and failure to satisfy customers , to achieve the effect of reducing the degree of migration effect, strong intuitiveness, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

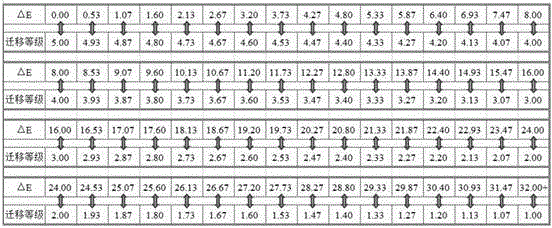

Image

Examples

Embodiment 1

[0034] 1) 175kg 2-amino-4-chloro-5-methylbenzene sodium sulfonate, 215kg / 30% concentrated hydrochloric acid stirring solution, add 250kg 30% sodium nitrite aqueous solution at 5℃~10℃ to carry out diazotization reaction, Stir for 1 hour to get the diazo liquid for use;

[0035]2) Add 1300kg of water, 250kg of liquid caustic soda and 140kg of 2,3 acid to the reaction kettle, stir at a temperature of 40 to 50°C to obtain a clear liquid, and add 100kg of water to the rosin liquid (30kg rosin + 15kg / 30% liquid caustic soda + 300kg) under stirring. water);

[0036] 3) Inject the diazo liquid into the reaction kettle at 10°C to 20°C for coupling reaction, and stir for 2 hours after adding the diazo liquid; after warming up to 35-45°C, adjust the pH of the system to 8-8.5 and stir for 30 minutes , then add the inorganic calcium compound, heat up to 80 ~ 85 ℃ for 30 minutes, then drop to room temperature for filtration, and dry the filter cake at 85 ~ 95 ℃ to obtain red pigment 48:2 Y...

Embodiment 2

[0039] 1) 175kg 2-amino-4-chloro-5-methylbenzene sodium sulfonate, 215kg / 30% concentrated hydrochloric acid stirring solution, add 250kg 30% sodium nitrite aqueous solution at 5℃~10℃ to carry out diazotization reaction, Stir for 1 hour to get the diazo liquid for use;

[0040] 2) Add 1300kg of water, 250kg of liquid caustic soda and 140kg of 2,3 acid to the reaction kettle, stir at a temperature of 40 to 50°C to obtain a clear liquid, and add 100kg of water under stirring and add S-rosin liquid (30kg S-rosin + 15kg / 30% liquid) alkali+300kg water);

[0041] 3) Inject the diazo liquid into the reaction kettle at 10°C to 20°C for coupling reaction, and stir for 2 hours after adding the diazo liquid; after warming up to 35-45°C, adjust the pH of the system to 8-8.5 and stir for 30 minutes , then add the inorganic calcium compound, heat up to 80 ~ 85 ℃ for 30 minutes, then drop to room temperature for filtration, and dry the filter cake at 85 ~ 95 ℃ to obtain red pigment 48:2 Yiel...

Embodiment 3

[0044] 1) 175kg 2-amino-4-chloro-5-methylbenzene sodium sulfonate, 215kg / 30% concentrated hydrochloric acid stirring solution, add 250kg 30% sodium nitrite aqueous solution at 5℃~10℃ to carry out diazotization reaction, Stir for 1 hour to get the diazo liquid for use;

[0045] 2) Add 1300kg of water, 250kg of liquid caustic soda and 140kg of 2,3 acid to the reaction kettle, stir at a temperature of 40 to 50°C to obtain a clear liquid, and add 100kg of water under stirring and add S-rosin liquid (30kg S-rosin + 15kg / 30% liquid) alkali+300kg water);

[0046] 3) Inject the diazo liquid into the reaction kettle at 10°C to 20°C for coupling reaction, and stir for 2 hours after adding the diazo liquid; after warming up to 35-45°C, adjust the pH of the system to 8-8.5 and stir for 30 minutes , then add the inorganic calcium compound, heat up to 80 ~ 85 ℃ for 30 minutes, then drop to room temperature for filtration, and dry the filter cake at 85 ~ 95 ℃ to obtain red pigment 48:2 Yiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com