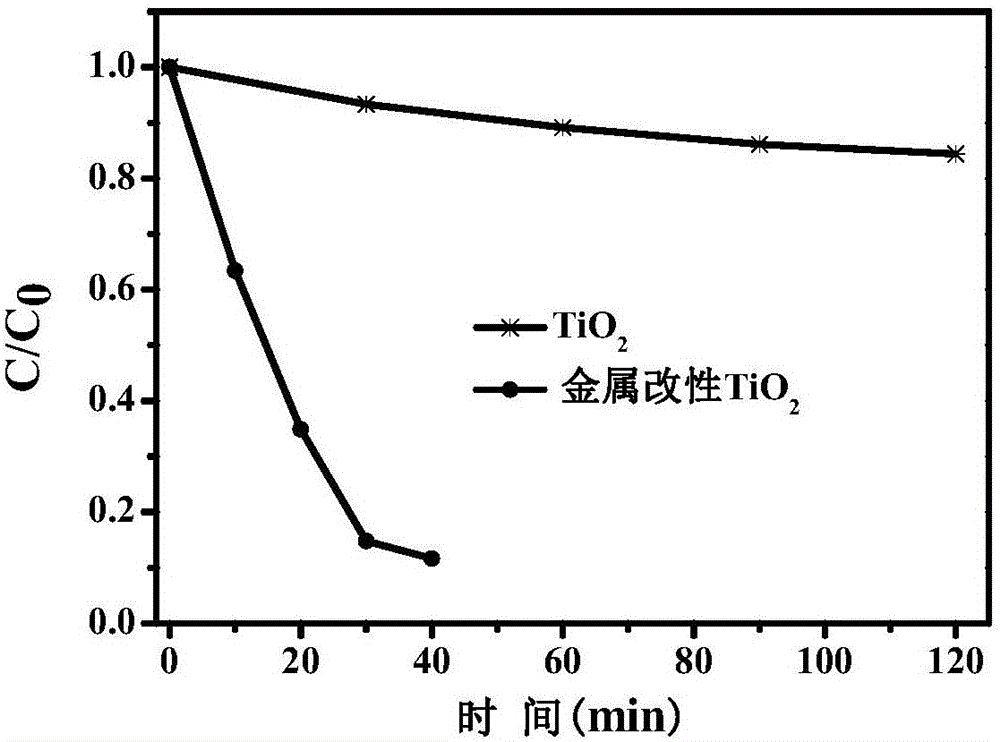

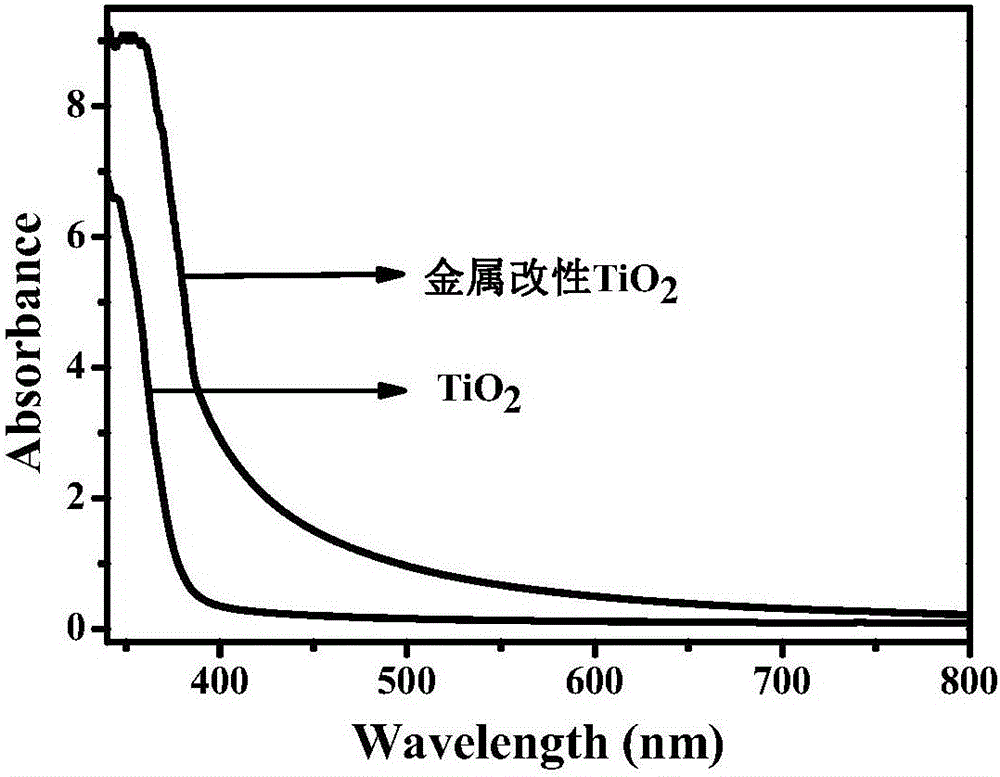

Metal modified titanium dioxide aqueous sol with high visible light activity, as well as synthesis and application of metal modified titanium dioxide aqueous sol

A titanium dioxide and metal modification technology, which is applied in the fields of inorganic nanomaterials and photocatalysis, can solve the problems of little improvement in catalyst activity, weak crystal activity, poor stability, etc., and achieves good sol dispersion stability, simple process operation, and efficient catalysis. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Dissolve tetrabutyl titanate in absolute ethanol solution, wherein the volume ratio of tetrabutyl titanate to absolute ethanol is 1:2, and mix evenly to obtain colorless and transparent dispersion A; (2) Disperse Solution A is slowly added dropwise into the nitric acid solution containing platinum nitrate and potassium chloroplatinate, wherein the molar ratio of platinum nitrate to potassium chloroplatinate is 0.01, the molar ratio of metal to titanium is 0.05%, the pH of the acidic solution is 0.5, and the dispersion The volume ratio of liquid A to acidic solution is 0.01. The mixed solution was stirred and reacted at 45 degrees for 4 hours to synthesize the dispersion B; (3) the above dispersion B was moved into a stainless steel reactor lined with polytetrafluoroethylene, and hydrothermally treated at 100 degrees for 4 hours; (4) the hydrothermally treated Reactor is cooled to room temperature, centrifuged and washed, water is added to make the solid content 0.1%...

Embodiment 2

[0031] (1) Dissolve tetraethyl titanate in isopropanol solution, wherein the volume ratio of tetraethyl titanate to isopropanol is 1:10, mix well to obtain colorless and transparent dispersion A; (2) disperse Solution A is slowly added dropwise to the hydrochloric acid solution containing copper nitrate and sodium chloroaurate, wherein the molar ratio of copper nitrate to sodium chloroaurate is 5, the molar ratio of metal to titanium is 5%, the pH of the acidic solution is 3, and the dispersion The volume ratio of liquid A to acidic solution is 1. The mixed solution was stirred and reacted at 95 degrees for 24 hours to synthesize the dispersion B; (3) the above-mentioned dispersion B was moved into a stainless steel reactor lined with polytetrafluoroethylene, and hydrothermally treated at 200 degrees for 48 hours; (4) the hydrothermally treated Cool the reaction kettle to room temperature, centrifugally wash, add water so that the solid content is 10%, and use 500 watts of ult...

Embodiment 3

[0033] (1) Dissolve tetraisopropyl titanate in methanol solution, wherein the volume ratio of tetraisopropyl titanate to methanol is 1:5, and mix evenly to obtain colorless and transparent dispersion A; (2) Dispersion A Slowly add it dropwise to the nitric acid solution containing ferric chloride and potassium chloroplatinate, wherein the molar ratio of ferric chloride to potassium chloroplatinate is 1, the molar ratio of metal to titanium is 0.5%, the pH of the acidic solution is 2, disperse The volume ratio of liquid A to acidic solution is 0.6. The mixed solution was stirred and reacted at 75 degrees for 12 hours to synthesize the dispersion B; (3) the above-mentioned dispersion B was moved into a stainless steel reactor lined with polytetrafluoroethylene, and hydrothermally treated at 160 degrees for 24 hours; (4) the hydrothermally treated Cool the reaction kettle to room temperature, centrifugally wash, add water so that the solid content is 5%, and use 200 watts of ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com