Method for preparing transparent aluminum hydroxide liquid dispersion

An aluminum hydroxide, liquid phase dispersion technology, applied in the chemical field, can solve the problems of serious powder particle agglomeration, particle agglomeration, complex preparation process, etc., and achieve the effect of simplifying the process production process, avoiding agglomeration and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

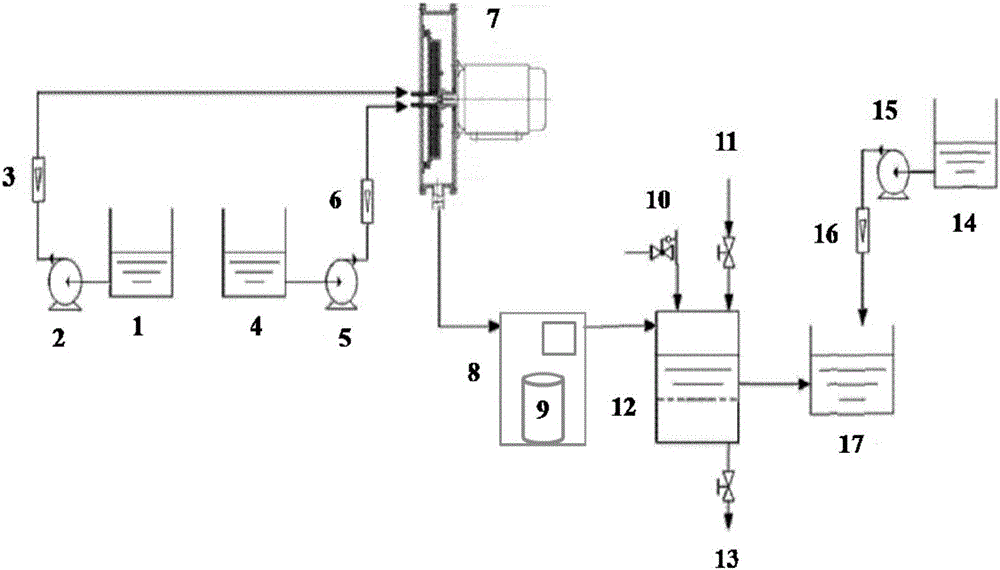

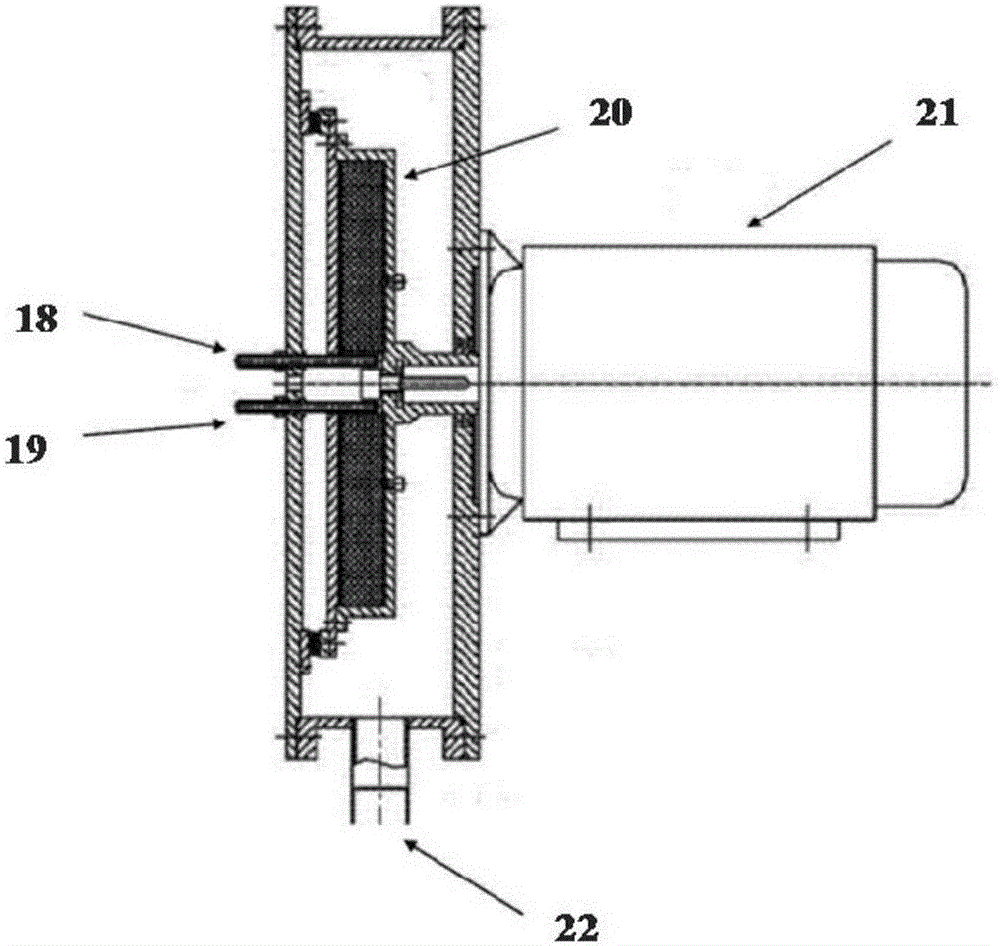

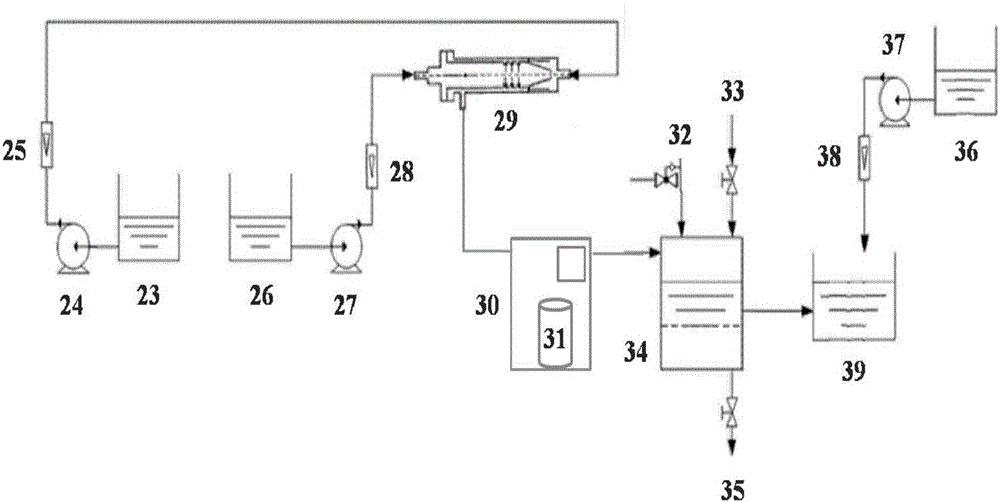

Embodiment 1

[0068] Adopt anhydrous aluminum chloride preparation 1000g concentration to be the aluminum chloride aqueous solution of 30wt% and transfer in the aluminum salt solution storage tank; Adopt the 28wt% strong ammonia water preparation 1600g concentration to be the ammonia solution of 18wt% and transfer in the lye storage tank ; Turn on the high-gravity rotating packed bed device and adjust the rotor speed to 1500rpm; turn on the feed pump to transport the aluminum salt solution and lye to the inside of the rotating bed for precipitation and crystallization reaction, and control the feed line speed of the aluminum salt solution to 3.5m / s, the feeding linear velocity of the lye is 5.6m / s, and the reaction temperature is 65°C; after the feeding of the two raw material liquids is completed, close the high-gravity rotating packed bed device, and collect the All the obtained suspensions were transferred into the hydrothermal reaction kettle; the hydrothermal reaction kettle was sealed...

Embodiment 2

[0070] Adopt aluminum chloride hexahydrate preparation 1800g concentration to be the aluminum chloride aqueous solution of 1.4wt% and transfer in the aluminum salt solution storage tank; Adopt sodium hydroxide preparation 2250g concentration to be the sodium hydroxide aqueous solution of 1wt% and transfer to the lye storage tank Middle; turn on the high-gravity rotating packed bed device and adjust the rotor speed to 2000rpm; turn on the feed pump to transport the aluminum salt solution and lye to the rotating bed at the same time for precipitation and crystallization reaction, and control the feed line speed of the aluminum salt solution to 7.2 m / s, the feeding linear velocity of the lye is 9m / s, and the reaction temperature is 25°C; after the feeding of the two raw material liquids is completed, close the high-gravity rotating packed bed device, and collect the All the obtained suspensions were transferred into the hydrothermal reaction kettle; the hydrothermal reaction kettl...

Embodiment 3

[0074] It is the aluminum nitrate ethanol solution of 10wt% that adopts nonahydrate aluminum nitrate preparation 1600g concentration and changes in the aluminum salt solution storage tank; The potassium hydroxide ethanol solution that adopts potassium hydroxide preparation 2000g concentration is 6wt% and changes in the lye storage tank ; Turn on the supergravity rotating packed bed device and adjust the rotor speed to 3000rpm; turn on the feed pump to transport the aluminum salt solution and lye to the inside of the rotating bed for precipitation and crystallization reaction, and control the feed linear velocity of the aluminum salt solution to 5m / s, the feeding linear velocity of the lye is 6.25m / s, and the reaction temperature is 45°C; after the feeding of the two raw material liquids is completed, close the high-gravity rotating packed bed device, and collect the All the suspensions were transferred into the hydrothermal reaction kettle; the hydrothermal reaction kettle was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com