Method for preparing synthesis gas from phosphogypsum

A technology for phosphogypsum and synthesis gas is applied in the field of phosphorus chemical waste residue recycling, which can solve the problems of high energy consumption, complex method and process, and achieve the effects of high output, easy availability of raw materials and easy process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

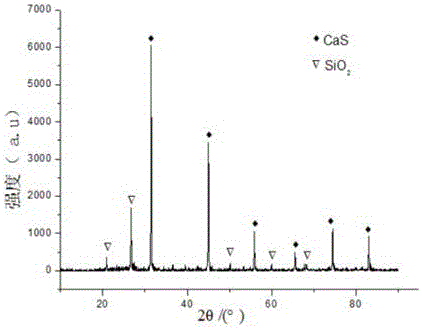

[0024] The method for preparing synthesis gas by using phosphogypsum described in this embodiment has the following specific steps: keeping the phosphogypsum and lignite at 105° C. for 2 hours, drying to remove free water, then grinding and sieving through 80 meshes, and sieving the phosphorus Gypsum and lignite in a ratio of 0.01 by mass, weigh 0.01 g of dried phosphogypsum powder and 1 g of lignite powder and mix them evenly, put them into a tube furnace, and after the tube furnace is deoxidized with nitrogen, the tube furnace is cooled from room temperature to room temperature. The temperature was raised to 950°C and kept for 1.5 hours. The phosphogypsum and lignite reacted fully, and gas was generated during the reaction. After the gas was cooled, it was dried on silica gel and then passed into the gas chromatograph to measure the concentration of various gases. It can be seen from the gas chromatograph , the amount of carbon monoxide and hydrogen in the generated gas slowl...

Embodiment 2

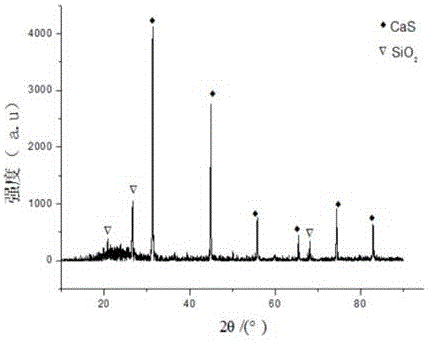

[0029] The method for preparing synthesis gas by using phosphogypsum described in this embodiment has the following specific steps: keeping the phosphogypsum and lignite at 100° C. for 3 hours, drying to remove free water, then grinding and sieving through 100 meshes, and the phosphorus Gypsum and lignite in a ratio of 0.4 by mass, weigh 0.4g of dried phosphogypsum powder and 1g of lignite powder and mix them evenly, put them in a tube furnace, and after the tube furnace is deoxidized with argon, the tube furnace The temperature was raised from room temperature to 875°C and kept for 2 hours. The phosphogypsum and lignite fully reacted, and gas was generated during the reaction process. After the gas was cooled, it was dried on silica gel and then passed into gas chromatography to measure the concentration of various gases. It can be seen that the amount of carbon monoxide and hydrogen in the generated gas slowly increases, and then gradually decreases as the reaction proceeds u...

Embodiment 3

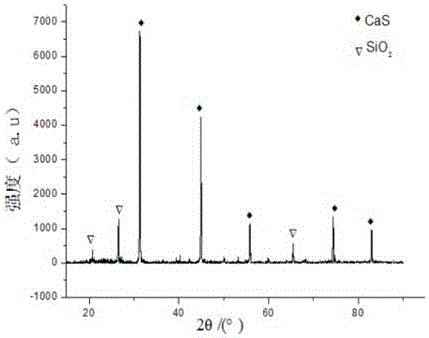

[0038]The method for preparing synthesis gas by using phosphogypsum described in this embodiment has the following specific steps: keeping the phosphogypsum and lignite at 120° C. for 2 hours, drying to remove free water, then grinding and sieving through a 60-mesh; Gypsum and lignite in a mass ratio of 0.75, weigh 0.75g of dried phosphogypsum powder and 1g of lignite powder and mix them evenly, put them into a tube furnace, and after the tube furnace is deoxidized with helium gas, the tube furnace is removed from the The room temperature was raised to 890°C, and the temperature was kept for 1.8 hours. The phosphogypsum and lignite fully reacted, and gas was generated during the reaction process. After the gas was cooled, it was dried on silica gel and then passed into the gas chromatograph to detect the concentration of various gases. From the gas chromatograph, it can be seen The amount of carbon monoxide and hydrogen in the generated gas gradually increased, and then gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com