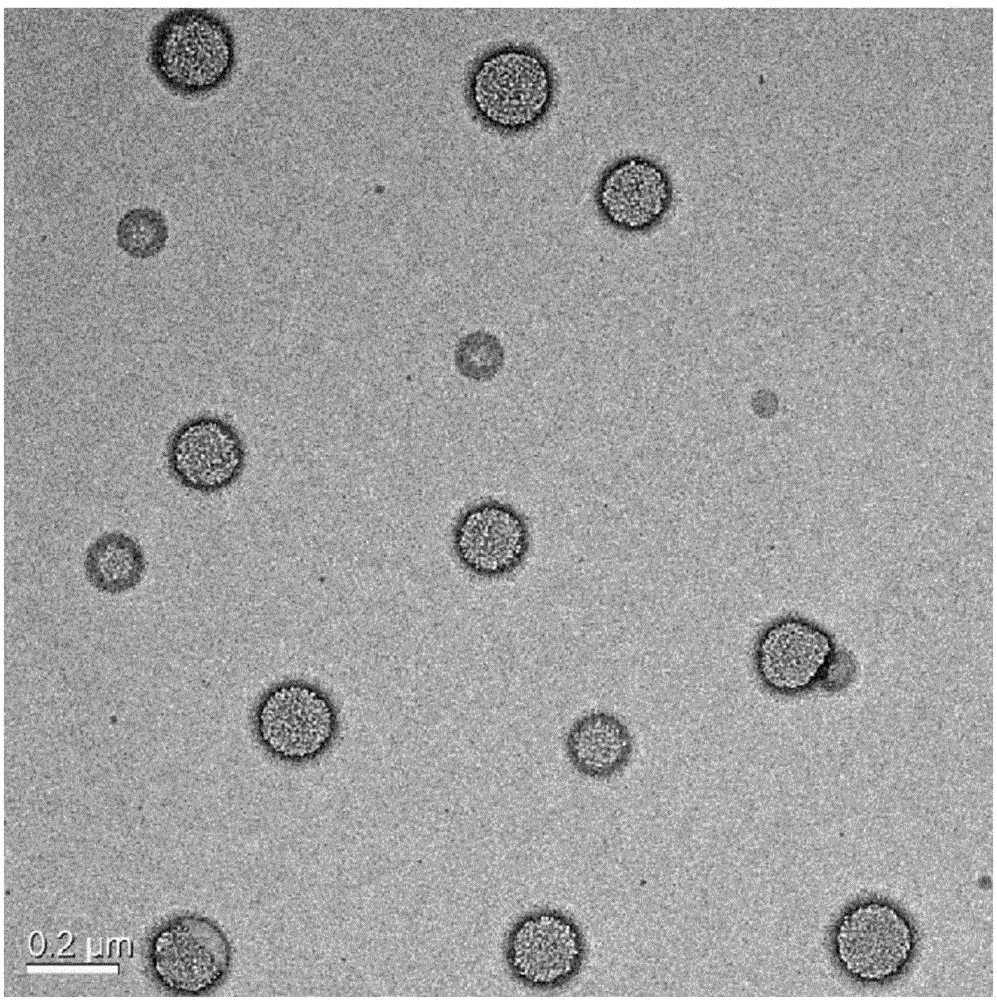

Method for preparing biodiesel by adopting magnetic carrier immobilized lipase

A technology of immobilized lipase and biodiesel, which is applied in the fields of immobilized on or in the inorganic carrier, biofuel, chemical industry, etc. It can solve the problems of poor stability of immobilized lipase, difficult separation of catalyst, large amount of alcohol, etc. Achieve the effects of improving mass transfer efficiency and conversion rate, uniform catalyst distribution, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

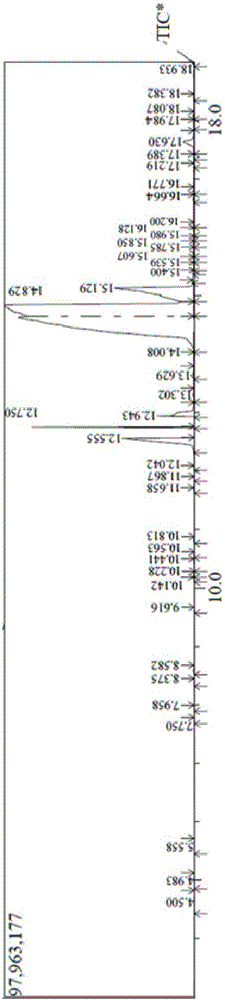

Embodiment 1

[0024] Example 1 Catalyzed transesterification of olive oil to prepare biodiesel

[0025] Using olive oil as raw material, the transesterification experiment was carried out with the prepared immobilized lipase magnetic nanoparticle catalyst. Put 2ml of olive oil and 330ml of methanol (alcohol to oil molar ratio 4:1) mixture in a test tube, add 10% of water (accounting for 10% of the total volume of oleyl alcohol and water), and then add 5% of the above catalysts (accounting for oil , alcohol, water, and 5% of the total mass of the catalyst), placed in a shaker for reaction at a temperature of 40° C. and a rotation speed of 160 rpm for 4 hours. After the reaction was completed, the sample was taken out and centrifuged at 10,000 rpm for 2 minutes, then the upper layer liquid was taken to measure the methyl ester content, and the transesterification efficiency was found to be 98.84%.

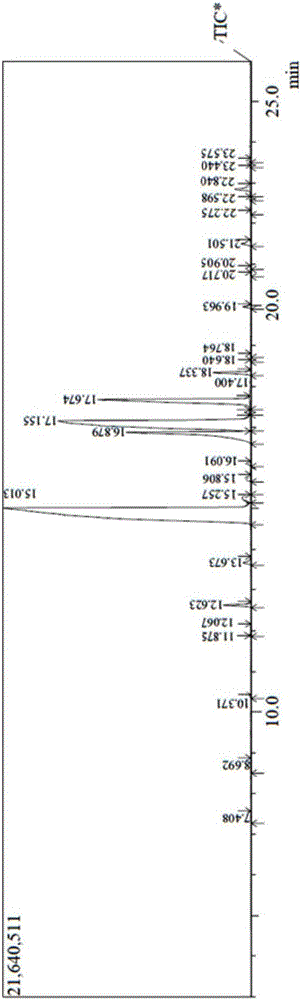

Embodiment 2

[0026] Example 2 Preparation of Biodiesel by Catalytic Waste Oil Transesterification

[0027] Using gutter oil as raw material, the transesterification experiment was carried out with the prepared immobilized lipase magnetic nanoparticle catalyst. The waste oil raw material is provided by Chengdu Shufeng Co., Ltd. After mechanical removal of impurities, adsorption and filtration of bentonite adsorbent, water washing and high-speed rotating centrifugation to remove water, it is used directly after deacidification with methanol esterification. The main characteristics of waste oil are as follows: acid value 28.87mgKOH / g; free fatty acid 10.27%; average molecular weight 885.68. Waste oil and methanol (alcohol-oil molar ratio 12:1) mixture are packed in test tube, add 15% water (accounting for 15% of oleyl alcohol and water total volume), then add 8% above-mentioned catalyst (accounting for oil, alcohol , water, and 8% of the total mass of the catalyst), placed in a shaker for re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com