Thermosensitive composition and solvent-free preparing method thereof

A composition and solvent-free technology, applied in the manufacture of rayon, rayon made of viscose, single-component polyester rayon, etc., can solve the problems of material leakage, achieve low cost, wide range of sources, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A temperature-sensitive composition and a preparation method thereof are as follows:

[0058] 1) After fully grinding the expanded perlite, sieving to obtain micron-sized expanded perlite powder;

[0059] 2) the hydrated inorganic salt CaCl 2 ·6H 2 O. KNO 3 , alumina, SrCl 2 ·6H 2 After O is mixed, it is added to the expanded perlite powder in (1) in stages, heated, and kept for adsorption; after the adsorption is completed, add Na 2 SiO 3 9H 2 O, insulation adsorption;

[0060] 3) Solidify the silicate into silicon dioxide to obtain the temperature-sensitive composition using inorganic hydrated salt as the temperature-sensitive material.

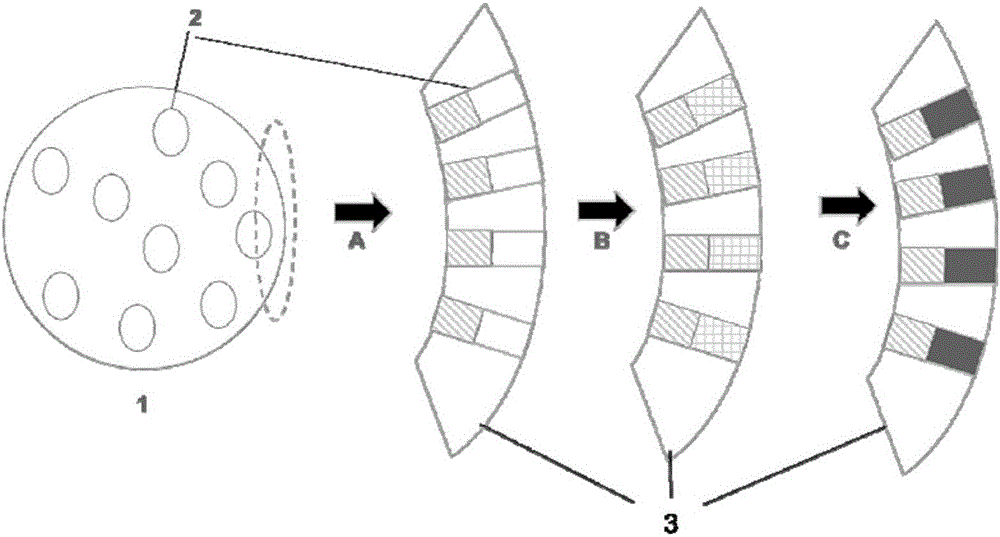

[0061] like figure 1 Shown in is a schematic diagram of the principle of the solvent-free preparation method of the temperature-sensitive composition. In the figure, 1 is a porous material, 2 is a pore structure, and 3 is a partially enlarged porous material; A is the process of gradually absorbing inorganic hydrate salts, ...

Embodiment 2

[0066] A temperature-sensitive composition and a preparation method thereof are as follows:

[0067] 1) Reflux the commercially available silica in the ethanol solution of silane coupling agent KH550 for a certain period of time, carry out hydrophilic modification on the nanopores of silica, filter and sieve to obtain submicron porous silica powder ;

[0068] 2) Add the liquid crystal material to the silicon dioxide powder in (1) one by one, heat, heat-preserve and adsorb; after the adsorption is completed, add TDI (toluene diisocyanate) to heat-preserve and adsorb;

[0069] 3) adding a small amount of butanediol and triethylenetetramine, raising the temperature to solidify and crosslink the TDI, and obtain the temperature-sensitive composition using liquid crystal as the temperature-sensitive material.

[0070] 4) blending and granulating the obtained temperature-sensitive composition with polylactic acid pellets, and then melt-spinning to obtain a temperature-sensitive poly...

Embodiment 3

[0073] A temperature-sensitive composition and a preparation method thereof are as follows:

[0074] 1) Sieving commercially available silicon dioxide to obtain submicron porous silicon dioxide powder;

[0075] 2) Add polyethylene glycol to the silicon dioxide powder in (1) one by one, heat, heat-insulate and adsorb; after the adsorption is completed, add epoxy resin, heat-insulate and adsorb;

[0076] 3) adding an epoxy curing agent, raising the temperature to cure and crosslink the epoxy resin, and obtain the temperature-sensitive composition using polyethylene glycol as the temperature-sensitive material.

[0077] 4) blending and granulating the obtained temperature-sensitive composition with polypropylene cutting pellets, and then melt-spinning to obtain a temperature-sensitive polypropylene fiber.

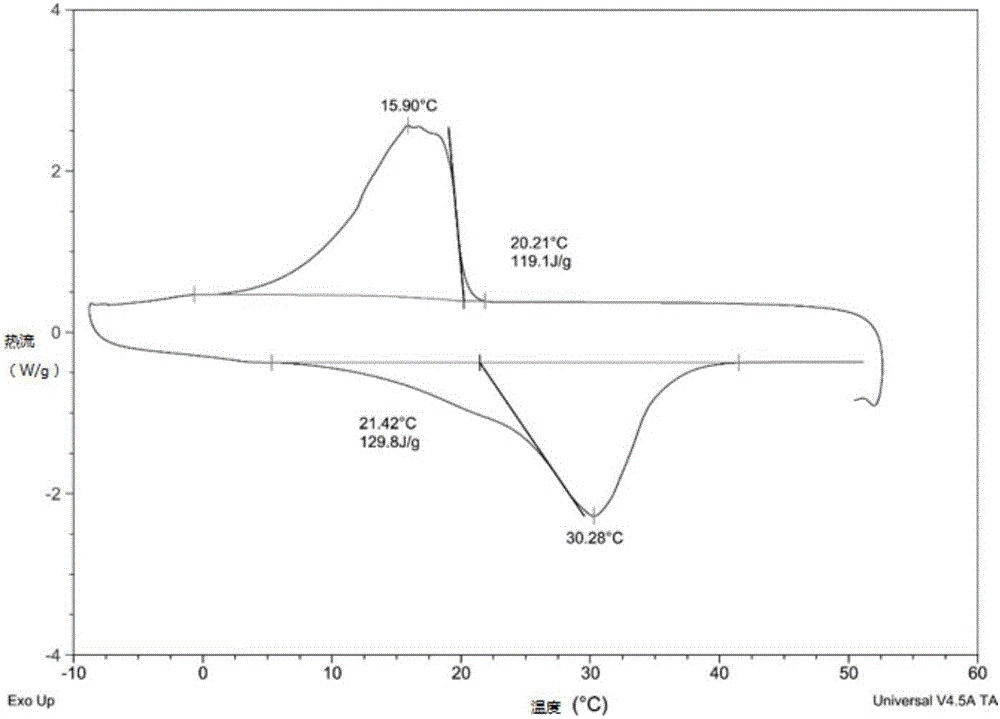

[0078] like Figure 4 Shown is the DSC standard curve of the temperature-sensitive polypropylene fiber with a temperature-sensitive material content of about 25% (mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com