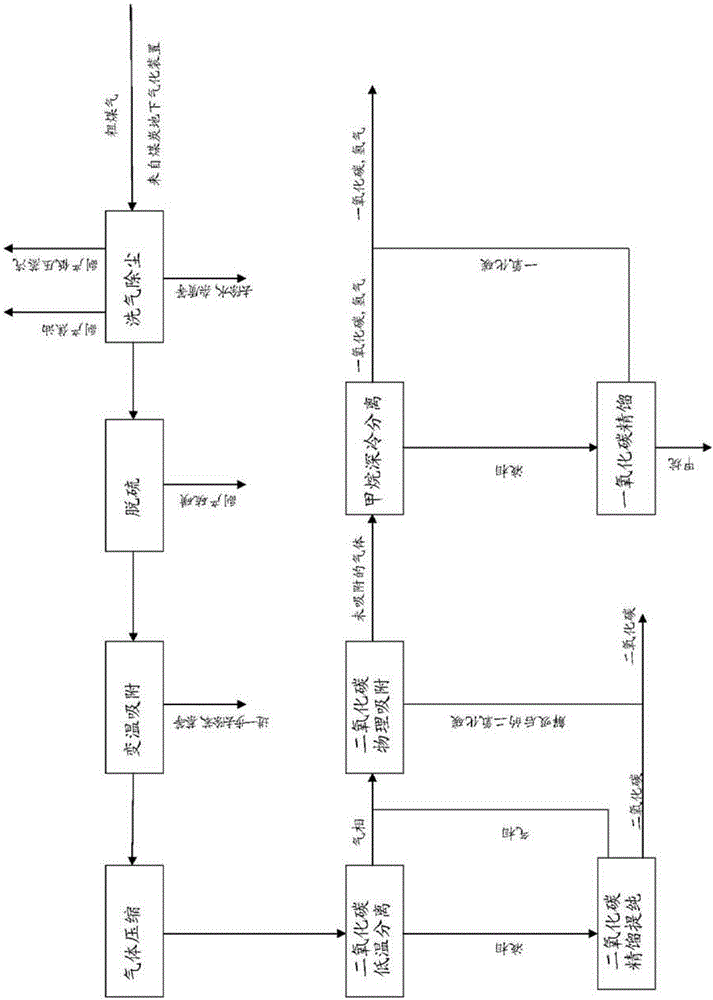

Gas purification and separation method based on underground coal gasification

An underground gasification and gas purification technology, applied in the field of by-product electricity, coal tar, and sulfur, to achieve the effects of diverse products, short gas separation process, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

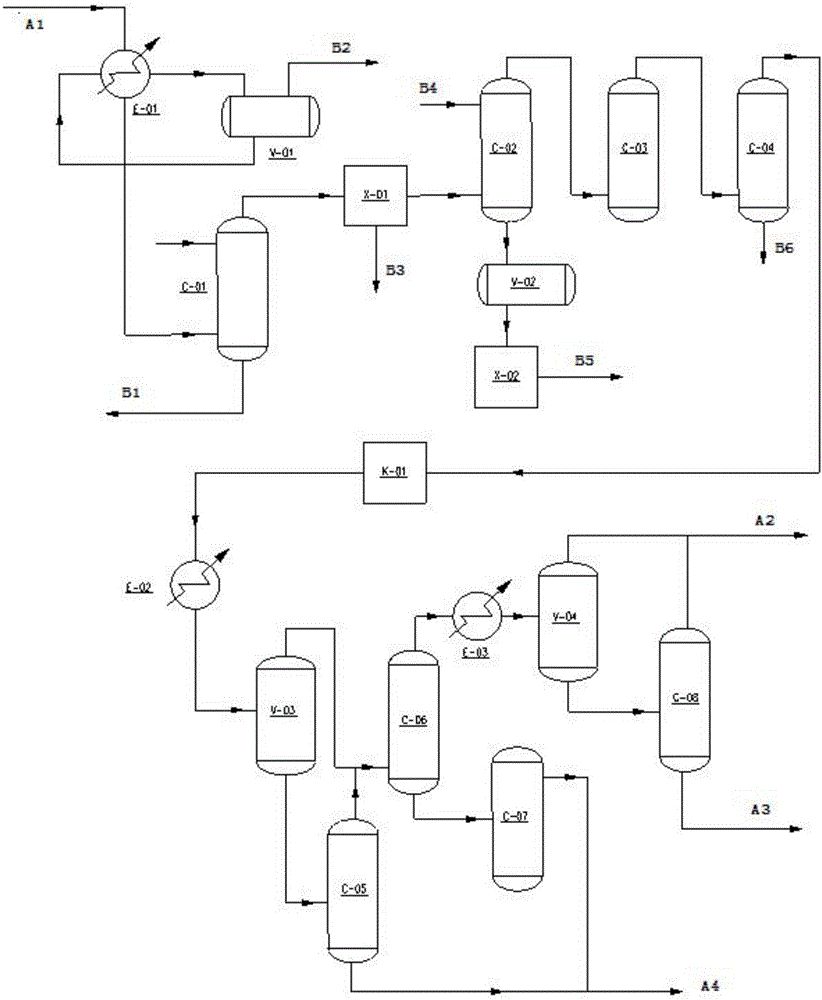

Method used

Image

Examples

Embodiment 1

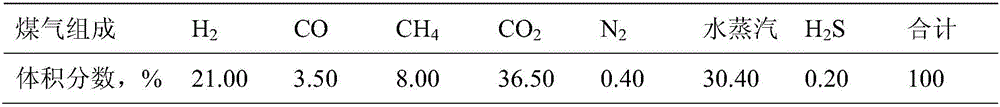

[0052] The crude gas produced by the underground coal gasification unit has a temperature of 250°C and a pressure of 0.6MPa, and the processing capacity is equivalent to dry gas 100×10 4 N m 3 / d, the main composition of crude gas is shown in Table 1, and the composition of impurities in crude gas is shown in Table 2.

[0053] Table 1 Main components of crude gas

[0054]

[0055] Table 2 Composition of impurities in crude gas

[0056]

[0057] The treatment process is as follows: the crude gas is first heat-exchanged by the low-pressure boiler to 150°C to recover the preheated by-product low-pressure steam, and then enters the gas scrubber, where the gas is in countercurrent contact with cold water to cool the gas, and the water vapor in the crude gas Liquefaction with some impurities to remove most of the impurities such as water and tar, dust, thiophene, carbon disulfide, crude benzene, ammonia, etc. After passing through the scrubber, the gas enters the electrostat...

Embodiment 2

[0061] The crude gas produced by the underground coal gasification device has the same treatment capacity and crude gas composition as in Example 1. The treatment process is as follows: the crude gas first undergoes the initial purification process, is recovered and preheated through boiler heat exchange, dust and water are removed through the scrubber and electrostatic precipitator to recover tar, and H2 is removed through wet desulfurization and dry desulfurization. 2 S, recover sulfur 157Kg / h, control the gas outlet temperature in the initial purification process to 40°C, pressure 0.20Mpa, after the initial purification process, remove the moisture and impurities in the crude gas 15513Kg / h, at this time the tar and dust in the impurity content3 、H2S3 . The initially purified gas is compressed and cooled for gas-liquid separation to control CO 2 The cryogenic separation temperature is -35°C, and the CO 2 The separation effect is shown in Table 3.

[0062] Table 3 Effect of...

Embodiment 3

[0066] The crude gas produced by the underground coal gasification device has the same treatment capacity and crude gas composition as in Example 1. The treatment process is as follows: the crude gas first undergoes the initial purification process, is recovered and preheated through boiler heat exchange, dust and water are removed through the scrubber and electrostatic precipitator to recover tar, and H2 is removed through wet desulfurization and dry desulfurization. 2 S, recover sulfur 157Kg / h, control the gas outlet temperature in the initial purification process to 40°C, pressure 0.19Mpa, after the initial purification process, remove the moisture and impurities in the crude gas 15513Kg / h, at this time the tar and dust in the impurity content3 、H2S3 . The initially purified gas is compressed and cooled for gas-liquid separation to control CO 2 The cryogenic separation pressure is 5.5MPaG, and the CO 2 The separation effect is shown in Table 4.

[0067] Table 4 The pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com