In-situ synthesized mullite whisker toughened 90 alumina ceramic and preparation method thereof

A technology of mullite whiskers and alumina ceramics, which is applied in the field of in-situ synthesis of mullite whiskers toughened 90 alumina ceramics and its preparation, can solve the problems of limited product adaptability and poor material compactness, etc. Achieve the effect of improving the softening point under load, good air tightness, and realizing large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

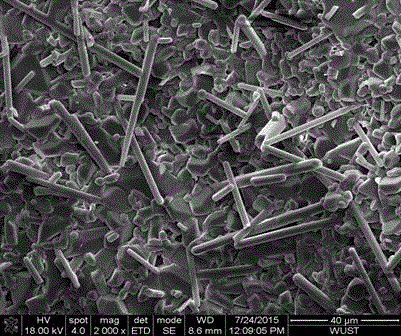

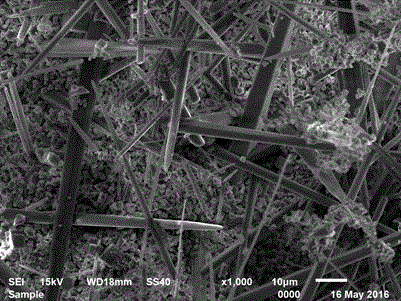

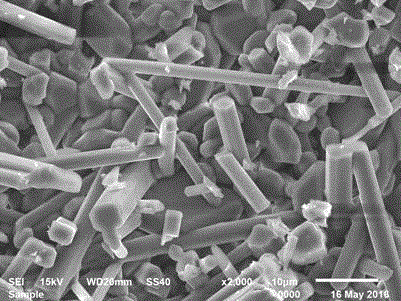

Image

Examples

Embodiment 1

[0033]A preparation method for in-situ synthesis of mullite whisker toughened 90 alumina ceramics, using 85 wt% α-alumina powder and 15 wt% silica powder as raw materials, and 18% trihydrate trihydrate Aluminum fluoride and 1% dry base titanium dioxide (pure titanium dioxide) by weight of raw materials are used as catalysts. Dry base titanium dioxide is generally added in the form of titanium dioxide sol. The amount of titanium dioxide sol added depends on the conversion of titanium dioxide concentration in the sol. The raw materials and catalysts are mixed in proportion , using water as the medium for ball milling for 24 hours, then adding 2% polyvinyl alcohol by weight of raw materials as a binder, after mixing for 30 minutes, adopting spray drying method to granulate, aging for 24 hours, and then adopting isostatic pressing dry method Forming is pressed into a green body under a pressure of 110 MPa, and the green body is refined, and the refined green body is raised to 1650 ...

Embodiment 2

[0036] A preparation method for in-situ synthesis of mullite whisker toughened 90 alumina ceramics, using 88wt% α-alumina powder and 12wt% silica powder as raw materials, and 18% fluorine trihydrate by weight of raw materials Aluminum powder and dry base titanium dioxide (pure titanium dioxide) with a weight of 1.5% of raw materials are used as catalysts. Dry base titanium dioxide is generally added in the form of titanium dioxide sol. The amount of titanium dioxide sol added depends on the conversion of titanium dioxide concentration in the sol. The raw materials and catalysts are mixed in proportion , using water as the medium for ball milling for 36 hours, then adding 1% polyvinyl alcohol by weight of the raw materials as a binder, mixing for 30 minutes, granulating by spray drying, aging for 24 hours, and then using isostatic pressing dry method Forming Press the green body under the pressure of 90 MPa, refine the green body, raise the temperature of the refined green body ...

Embodiment 3

[0039] A preparation method for in-situ synthesis of mullite whisker toughened 90 alumina ceramics, using 90 wt% α-alumina powder and 10 wt% silica powder as raw materials, and 10% trihydrate trihydrate Aluminum fluoride powder and dry base titanium dioxide (pure titanium dioxide) with a weight of 1.5% of the raw material are used as catalysts. Dry base titanium dioxide is generally added in the form of titanium dioxide sol. The amount of titanium dioxide sol added depends on the concentration of titanium dioxide in the sol. Ratio matching, ball milling with water as medium for 36 hours, then adding 2% polyvinyl alcohol by raw material weight as binder, after mixing for 30 minutes, adopting spray drying method to granulate, aging for 24 hours, and then using isostatic pressing Dry forming is pressed into a green body under a pressure of 100 MPa, and the green body is refined, and the refined green body is raised to 1600 °C at a heating rate of 2 °C / min, kept for 6 hours, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Whisker length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com