Clopidogrel sulfate solid tablets and preparation method thereof

A technology of clopidogrel sulfate and solid, which is applied in the field of medicine to achieve the effect of reasonable formula, easy industrial production and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

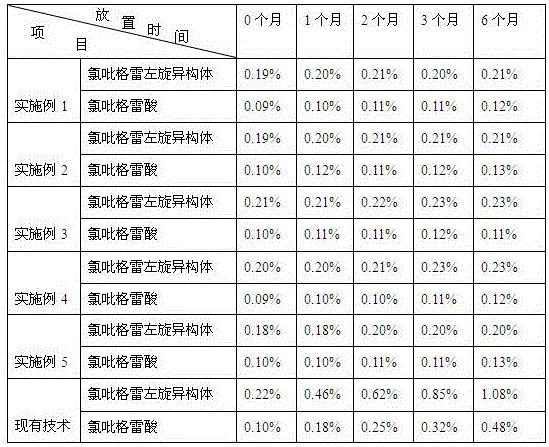

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Group ratio:

[0031] raw material name

Dosage

Clopidogrel bisulfate type I

75 parts by weight (calculated as clopidogrel free base)

20 parts by weight

Vitamin E

0.1 parts by weight

Maltose Fatty Acid Ester

10 parts by weight

Low-substituted hydroxypropyl cellulose

1 part by weight

diatomite

1 part by weight

talcum powder

1 part by weight

5 parts by weight

Modified micropowder silica gel

1 part by weight

[0032] Preparation:

[0033] (1) Filter the micropowder silica gel with hollow mesoporous structure to 100~200 meshes, add sodium polymethacrylate dispersant to the xylene organic solvent at a stirring speed of 1000r / min~5000r / min, and micropowder silica gel The mass volume ratio with the organic solvent is 1:40, stir and disperse for 1~2h to obtain a micropowder silica gel dispersion; raise the tem...

Embodiment 2

[0038] Group ratio:

[0039] raw material name

Dosage

Clopidogrel bisulfate type II

75 parts by weight (calculated as clopidogrel free base)

30 parts by weight

Vitamin E

1 part by weight

Hydroxypropyl-β-cyclodextrin

20 parts by weight

Low-substituted hydroxypropyl cellulose

1 part by weight

diatomite

3 parts by weight

polyethylene glycol

4 parts by weight

8 parts by weight

Modified micropowder silica gel

3 parts by weight

[0040] Preparation:

[0041](1) Filter micropowder silica gel with hollow mesoporous structure to 100~200 meshes, add dodecyl alcohol dispersant to xylene organic solvent at a stirring speed of 1000r / min~5000r / min, micropowder silica gel and The mass volume ratio of the organic solvent is 1:50, stir and disperse for 1~2h to obtain a micropowder silica gel dispersion; raise the temperatur...

Embodiment 3

[0046] Composition ratio (clopidogrel content 75mg / tablet):

[0047] raw material name

Dosage

Clopidogrel bisulfate type I

75 parts by weight (calculated as clopidogrel free base)

40 parts by weight

Vitamin E

2 parts by weight

compressible starch

30 parts by weight

Low-substituted hydroxypropyl cellulose

2 parts by weight

diatomite

3 parts by weight

6 parts by weight

10 parts by weight

Modified micropowder silica gel

6 parts by weight

[0048] Preparation:

[0049] (1) Filter micropowder silica gel with hollow mesoporous structure to 100~200 mesh, add triethanolamine dispersant to xylene organic solvent at a stirring speed of 1000r / min~5000r / min, micropowder silica gel and organic solvent The mass volume ratio is 1:60, stir and disperse for 1~2h to obtain a micropowder silica gel dispersi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com