Preparation and application in pharmacy field of silica medical microsphere

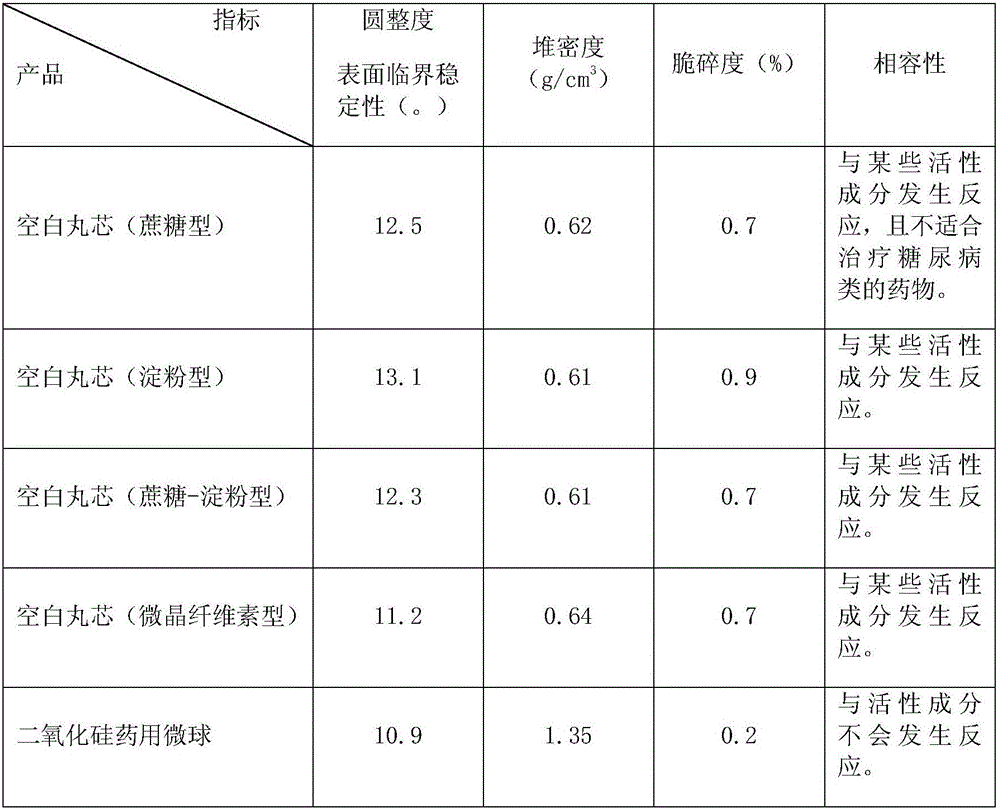

A technology of silica and microspheres, which is applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, microcapsules, etc., which can solve the problems of large coating weight gain, low product yield, and high breakage rate. problems, achieve the effect of reducing coating loss, high product yield and low breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

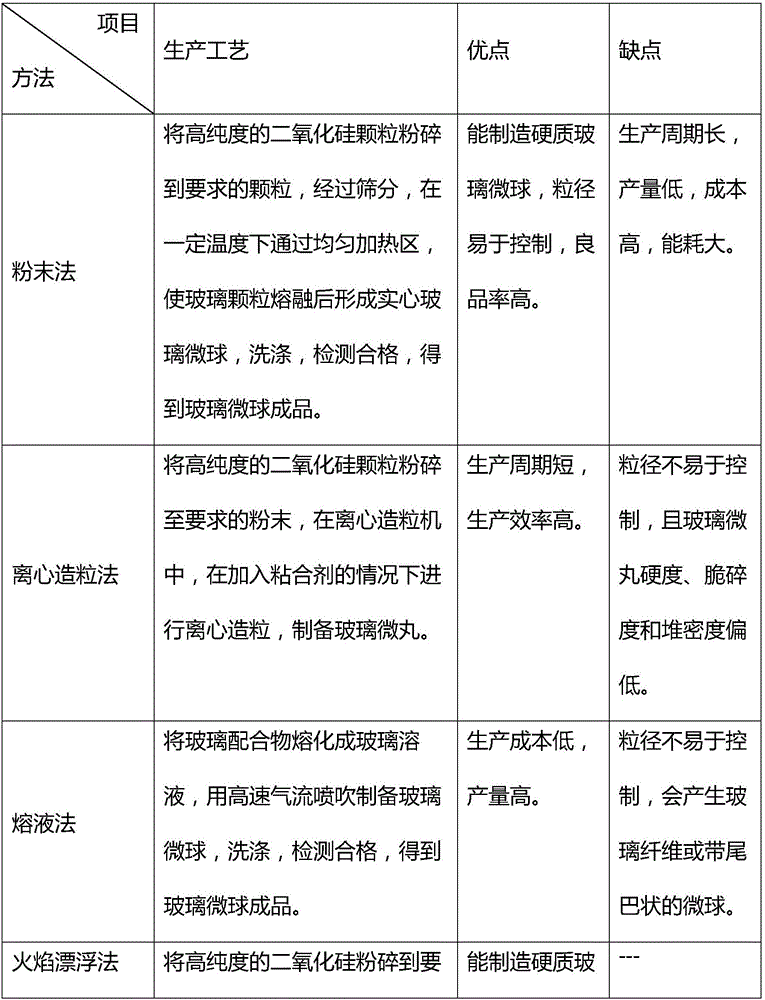

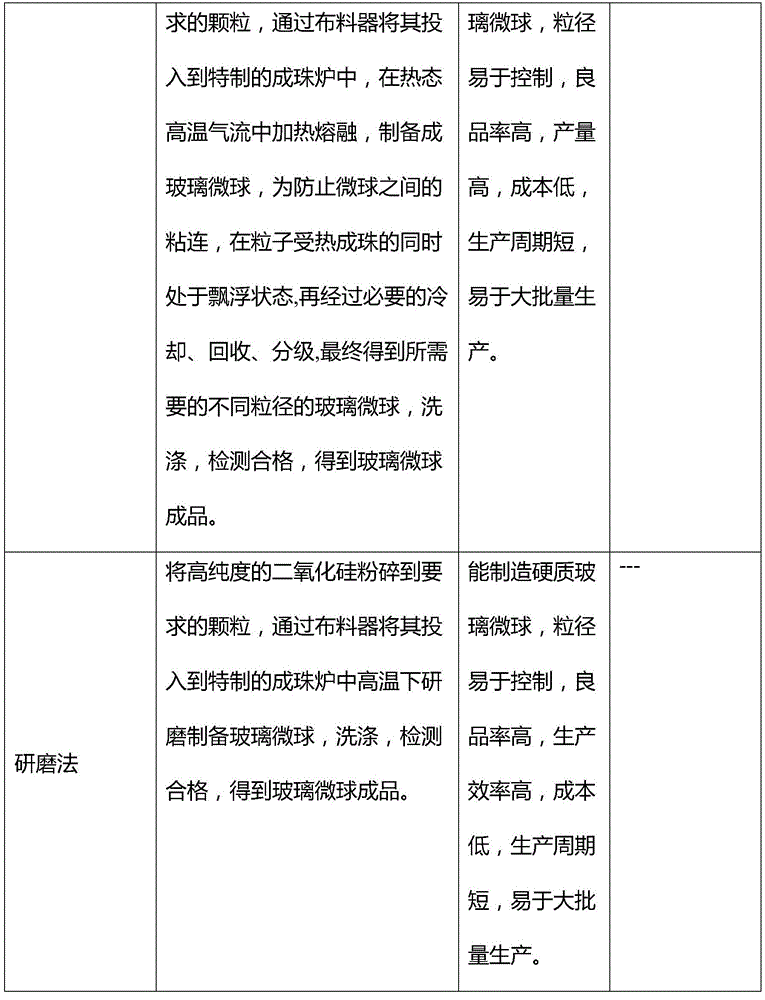

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 silica microsphere

[0033] Take 1 kg of silicon dioxide microspheres (80 mesh) prepared by melting prepared silicon dioxide microspheres or crystal ore with a silicon dioxide purity of 99.0% and grind them with a ball mill, put them into 10% hydrochloric acid solution, stir for 1 hour, and let stand , pour off the supernatant, add 1mol / L sodium hydroxide to the remaining concentrated silica microspheres to adjust the pH to 7, filter, wash with purified water, dry and sieve to obtain 80 mesh carbon dioxide Silica microspheres.

Embodiment 2

[0034] The preparation of embodiment 2 silica microspheres

[0035] Take 1 kg of silicon dioxide microspheres (100-120 mesh) prepared by melting prepared silicon dioxide microspheres or crystal ore with a silicon dioxide purity of 99.9% and grind them into 10% hydrochloric acid solution, and stir for 1 hour , stand still, pour off the supernatant, add 1mol / L sodium hydroxide to the remaining concentrated silica microspheres to adjust the pH to 7, filter, wash with purified water, dry and sieve to obtain 120 Silica microspheres.

Embodiment 3

[0036] The preparation method of embodiment 3 azithromycin dry suspension

[0037] Prepare the azithromycin drug-containing pellets first, coat the isolation layer, and then coat the slow-release layer to prepare the azithromycin taste-masking pellets, add auxiliary materials according to the characteristics of the dry suspension, and mix evenly.

[0038] (1) Preparation process of azithromycin drug-containing pellets

[0039] The prescription of azithromycin-containing pellets: silica microspheres (particle size: 0.075-0.10mm) 300g, azithromycin 150g (100 mesh), HPMC (E5) 10g, talcum powder 5g, 85% ethanol 2000mL.

[0040] Preparation process of medicinal solution: Add 10.0 g of HPMC (E5) to 2000 mL of 85% ethanol under stirring, dissolve until clear, add 150 g of azithromycin, continue stirring for 1 hour, add 5 g of talcum powder, and stir for 15 minutes to obtain a drug-containing solution.

[0041] Preparation of drug-containing pellets: Take 150-200 mesh silica microsph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com