Molybdenum diselenide/ferroferric oxide magnetic nano composite material, and preparation method and application thereof.

A technology of triiron tetroxide and molybdenum diselenide, which is applied in the field of nanomaterials, can solve the problems of complicated operation, difficult separation and recovery, consumables and the like, and achieves the effects of simple and easily controllable production process and high product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

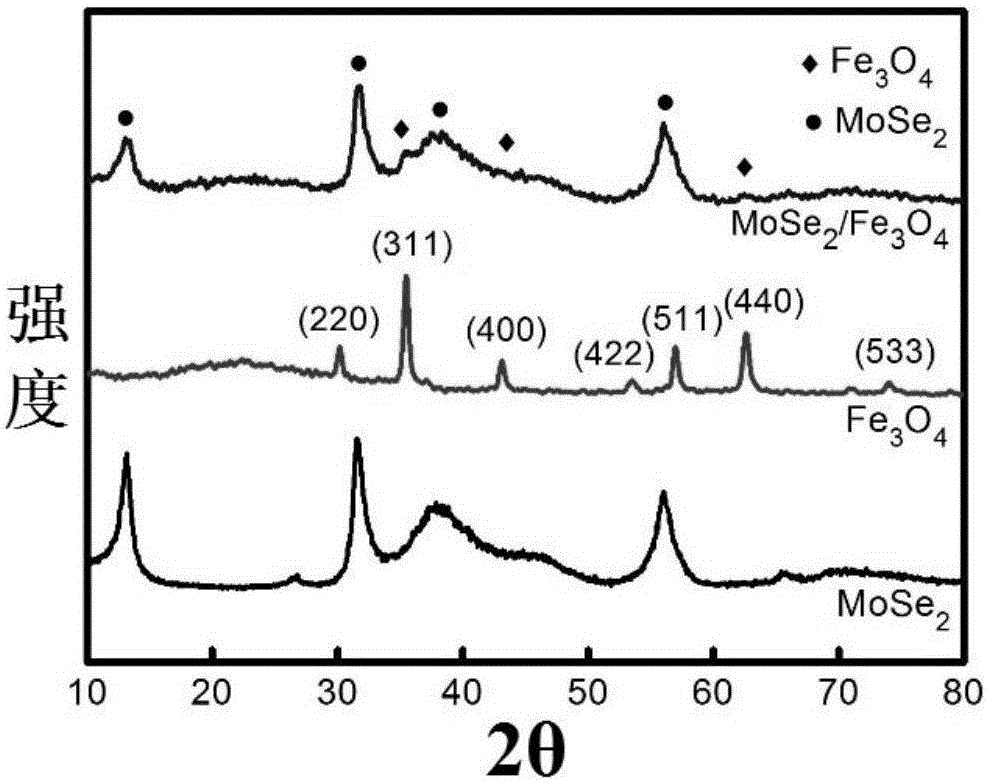

[0026] (1) Weigh 1.3714g Na respectively 2 MoO 4 2H 2 O, 1.5492g Se powder, 0.2595g NaBH 4 Dissolve in 20mL of distilled water, add to the above beaker one by one under magnetic stirring, stir well until the mixture is evenly dispersed, then add 20mL of ethanol, and continue to stir for 10min;

[0027] Then the blood-red mixed solution was transferred to a 50 mL high-temperature hydrothermal reaction kettle lined with polytetrafluoroethylene, sealed and put into a vacuum drying oven, and reacted at 220° C. for 24 hours. After the oven is naturally cooled to room temperature, pour out the upper liquid, collect the black product at the bottom, wash it with distilled water and absolute ethanol several times, and finally dry it at 60°C to obtain a black powder MoSe 2 nanoflowers.

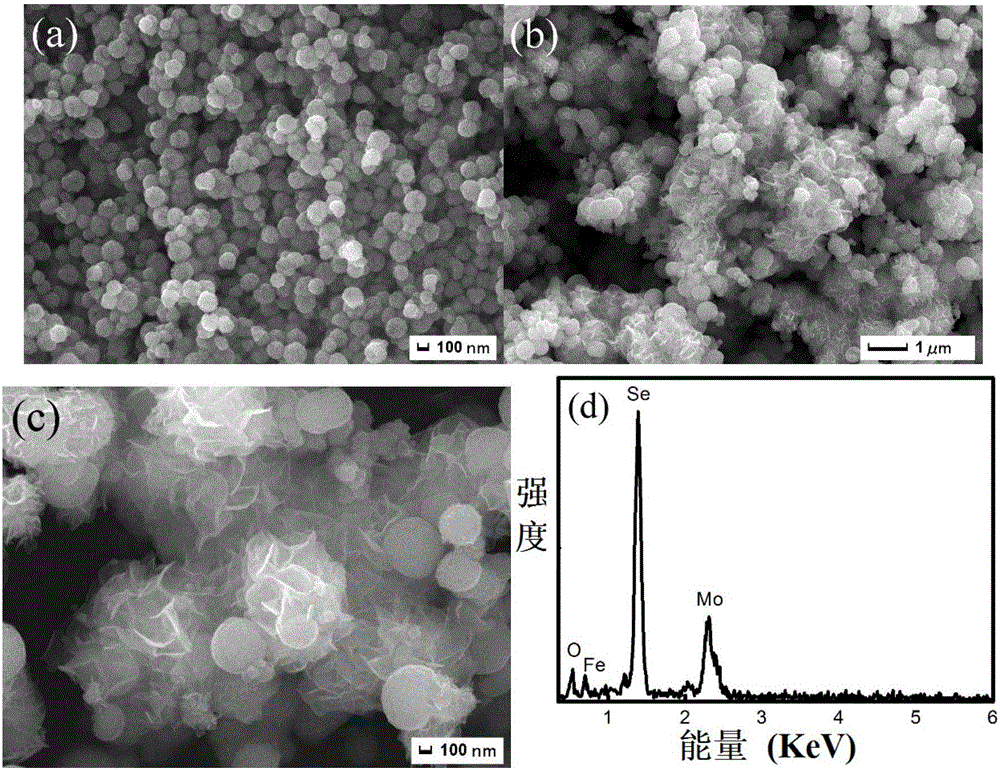

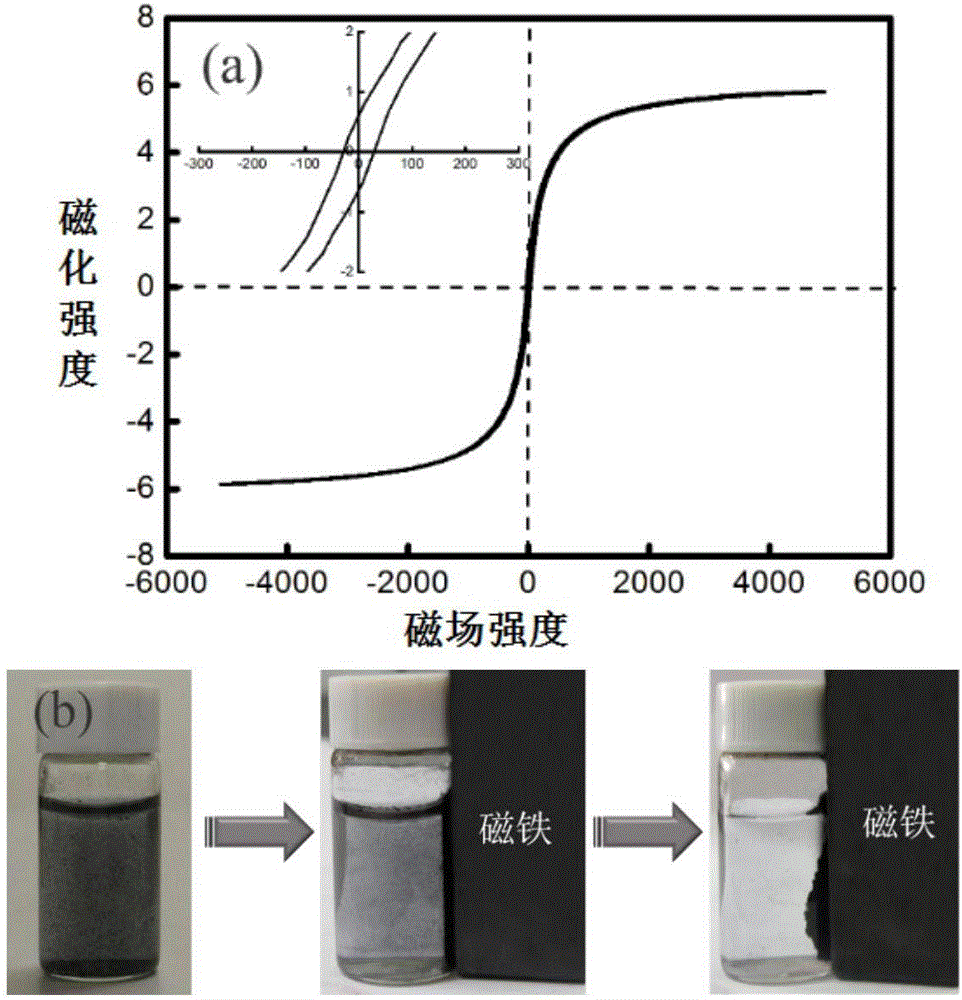

[0028] (2) 0.12g of MoSe prepared in step (1) 2 Dissolve in 30mL ethylene glycol, ultrasonically disperse for 1h. Then weigh 0.082g FeCl 3 ·6H 2O was added to the above solution under magnetic s...

Embodiment 2

[0031] Difference with embodiment 1 is that the catalyzer of step (1) is the KSCN of 1.98g;

[0032] The solvent in step (2) is 30mL of ethylene glycol and water mixed solvent (1:1), ultrasonically dispersed for 1h. Then weigh 0.0016gFeCl 3 ·6H 2 O was added to the above solution under magnetic stirring, and then 0.04 g of anhydrous sodium acetate was added after stirring for 5 minutes, and the stirring was continued for 10 minutes until the solution was uniformly dispersed, and the yellow mixture was transferred to a 50 mL hydrothermal reaction vessel with a Teflon liner The kettle was sealed, then put into a vacuum drying oven, and reacted at 130° C. for 12 hours. After the oven was naturally cooled to room temperature, the upper liquid was poured out, the black product was collected, washed several times with distilled water and absolute ethanol, and then dried at 60°C to obtain a black magnetic powder with a yield of 95%, Fe 3 o 4 10%, MoSe 2 90%. The adsorption rate...

Embodiment 3

[0034] Difference with embodiment 1 is: the catalyzer of step (1) is 1.44g NH 2 OH·HCl, molybdenum source is 1.2g (NH4) 2 MO 4 2H 2 O, the reaction condition is a temperature of 260°C and a time of 48h;

[0035] The solvent of step (2) is 30 mL of deionized water, and the reaction conditions are a temperature of 260° C. and a time of 24 h. Yield 92%, Fe 3 o 4 40%, MoSe 2 60%. The adsorption rate of the molybdenum diselenide / ferric oxide to the dye is 55%, and the adsorption amount of the molybdenum diselenide / ferric oxide to the dye is 38 mg / g at adsorption equilibrium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com