Processing technique of L-2-amino butyramide hydrochloride

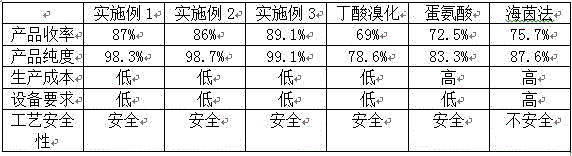

A technology of aminobutyramide and processing technology, which is applied in the field of medicine and chemical industry, can solve the problems of product purity not meeting the requirements of customers, unacceptable production cost, high temperature and pressure, etc., and achieve low cost, easy control of reaction, and equipment requirements low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The processing technology of present embodiment L-2-aminobutanamide hydrochloride, the specific steps of this processing technology are as follows:

[0024] (1) Add 2-chlorobutyric acid and hexamethylenetetramine into the reaction vessel, and stir evenly at room temperature to obtain a feed solution. The mass molar ratio of 2-chlorobutyric acid and hexamethylenetetramine is 1:0.2 ;

[0025] (2) Pass liquid ammonia into the feed liquid in step (1), the mass molar ratio of liquid ammonia usage to 2-chlorobutyric acid is 3:1, the reaction is carried out in the water phase, and the reaction temperature is controlled at 40°C. The reaction time is 20 hours;

[0026] (3) After the reaction in step (2), use the difference in the solubility of 2-aminobutyric acid and ammonium chloride in water, add water to dissolve, ethanol analysis, and suction filter to obtain 2-aminobutyric acid;

[0027] (4) Split 2-aminobutyric acid in step (3) with L-tartaric acid to obtain L-2-aminobut...

Embodiment 2

[0030] The processing technology of present embodiment L-2-aminobutanamide hydrochloride, the specific steps of this processing technology are as follows:

[0031] (1) Add 2-chlorobutyric acid and hexamethylenetetramine into the reaction vessel, and stir evenly at room temperature to obtain a feed solution. The mass molar ratio of 2-chlorobutyric acid and hexamethylenetetramine is 1:0.5 ;

[0032] (2) Pass liquid ammonia into the feed liquid in step (1), the mass molar ratio of liquid ammonia usage to 2-chlorobutyric acid is 4:1, the reaction is carried out in the water phase, and the reaction temperature is controlled at 60°C. The reaction time is 4 hours;

[0033] (3) After the reaction in step (2), use the difference in the solubility of 2-aminobutyric acid and ammonium chloride in water, add water to dissolve, ethanol analysis, and suction filter to obtain 2-aminobutyric acid;

[0034] (4) Split 2-aminobutyric acid in step (3) with L-tartaric acid to obtain L-2-aminobuty...

Embodiment 3

[0037] The processing technology of present embodiment L-2-aminobutanamide hydrochloride, the specific steps of this processing technology are as follows:

[0038] (1) Add 2-chlorobutyric acid and hexamethylenetetramine into the reaction vessel, and stir evenly at room temperature to obtain a feed solution. The mass molar ratio of 2-chlorobutyric acid and hexamethylenetetramine is 1:0.3 ;

[0039] (2) Pass liquid ammonia into the feed liquid in step (1), the mass molar ratio of liquid ammonia usage to 2-chlorobutyric acid is 3.5:1, the reaction is carried out in the water phase, and the reaction temperature is controlled at 50°C. The reaction time is 12 hours;

[0040] (3) After the reaction in step (2), use the difference in the solubility of 2-aminobutyric acid and ammonium chloride in water, add water to dissolve, ethanol analysis, and suction filter to obtain 2-aminobutyric acid;

[0041] (4) Split 2-aminobutyric acid in step (3) with L-tartaric acid to obtain L-2-aminob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com