A kind of electron transport material, preparation method and application thereof

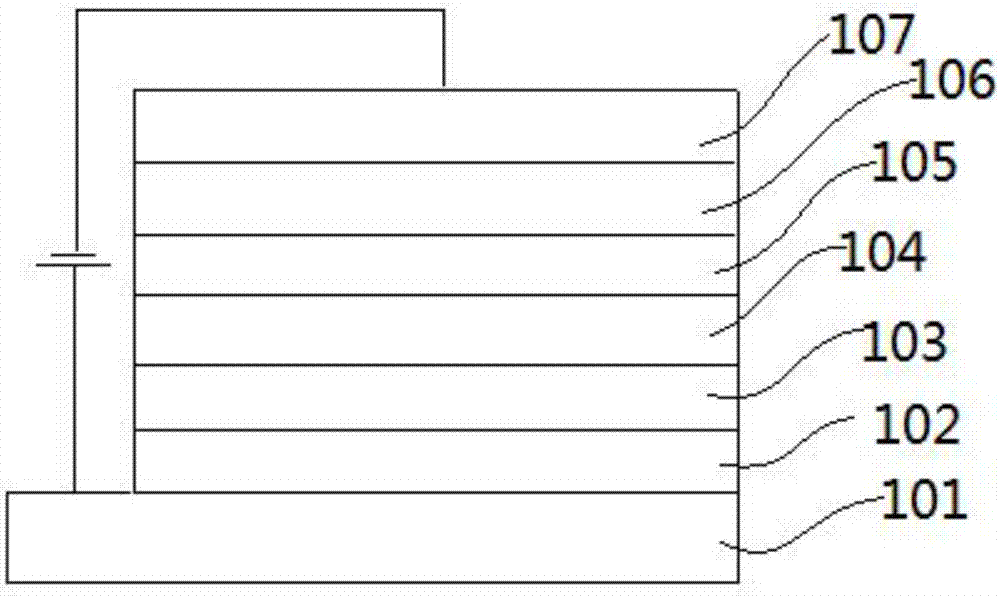

An electron transport material and carbon number technology, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of high driving voltage, not attracting too much attention, low luminous brightness and efficiency, and reduce the driving voltage. , The effect of improving charge migration ability and high electron transport performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

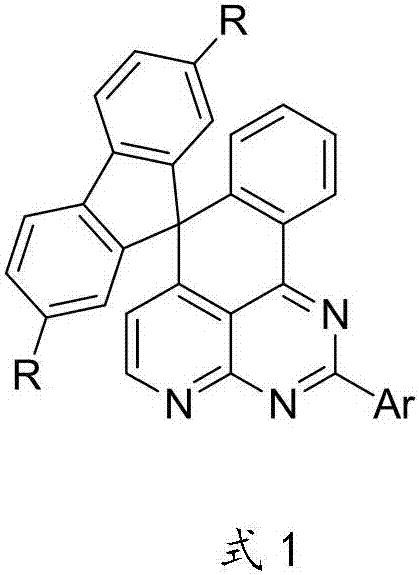

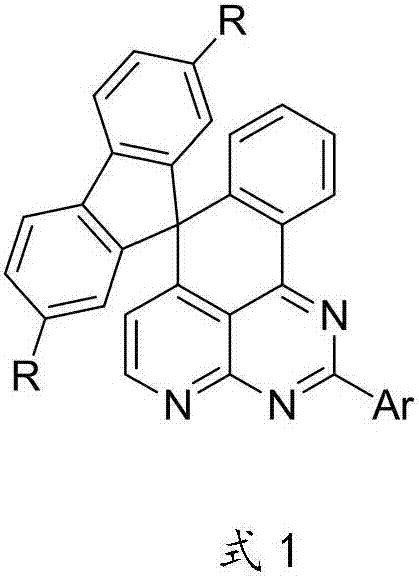

[0058] Embodiment 1: Preparation of aforementioned material 1

[0059] Step (1) Preparation of Intermediate A

[0060]

[0061] 200.2g (1mol) of 2,4-dichloropyrido[2,3-d]pyrimidine, 220g (1.1mol) of o-bromophenylboronic acid and 276g (2mol) of potassium carbonate were added to a mixture containing 600g water and 800g toluene After being placed in the mixed solvent of the tetraphenylphosphine palladium, under the protection of nitrogen, stir at room temperature for 20 minutes, then add 1 g tetrakistriphenylphosphine palladium, under the catalysis of tetrakistriphenylphosphine palladium, and keep the reaction for 24 hours at 80 ° C, and then The reaction of the compound 2,4-dichloropyrido[2,3-d]pyrimidine was detected by TLC, and then the system was separated, and the organic phase was spin-dried, and then column chromatography was carried out using petroleum ether and ethyl acetate to obtain The purified intermediate A is 272.5g, and the intermediate A is shown in the follo...

Embodiment 2

[0072] Embodiment 2: Preparation of aforementioned material 2

[0073] Adopt the same preparation method and raw material ratio as the preparation of material 1 in Example 1, wherein only phenylboronic acid is replaced by 1-naphthylboronic acid in step (4), and the rest remain unchanged. The final obtained material 2 was detected by high-performance liquid chromatography (HPLC for short), and the purity of material 2 was 99.7%, and the test value [M+1] was 496.1736, and the theoretical value was 496.1735 through high-resolution mass spectrometry.

Embodiment 3

[0074] Embodiment 3: Preparation of aforementioned material 3

[0075] The same preparation method and raw material ratio as in the preparation of material 1 in Example 1 were adopted, except that phenylboronic acid was replaced by 2-furanboronic acid in step (4), and the rest remained unchanged. The purity of the material 3 was 99.6% through high-performance liquid chromatography (HPLC for short), and the test value [M+1] was 436.1366 and the theoretical value was 436.1372 through high-resolution mass spectrometry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com