Method for preparing high-yield fluorescent silicon quantum dots by virtue of hydrothermal method or microwave method

A technology of silicon quantum dots and microwave method, applied in the field of preparation of nanomaterials, can solve the problems of inability to directly apply biological systems, unfavorable for large-scale production in factories, complicated operations, etc., and achieves high yield, good stability, acid resistance, Combining simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The method for synthesizing water-soluble silicon quantum dots by hydrothermal method with ureapropyltriethoxysilane as silicon source, its specific steps are as follows:

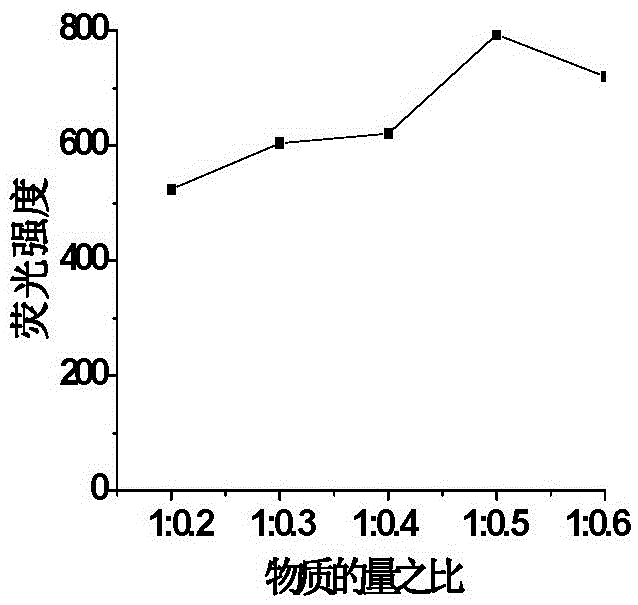

[0054] (1) Dissolve sodium citrate in deionized water under the protection of nitrogen, and then add ureapropyltriethoxysilane to control silicon source: sodium citrate molar ratio = 1:0.2, among which, ureapropyltriethoxysilane The concentration of oxysilane in water is 44mmol / L, and the concentration of sodium citrate in water is 8.8mmol / L. And adjust its pH=7 (NaOH, KOH, ammonia water, etc. can be used to adjust the pH), and then transfer the uniformly mixed solution into a 500ml high-pressure reactor and heat it to 200°C for 2.5 hours to obtain a large amount of quantum dot solution.

[0055] (2) Put the obtained silicon quantum dot solution in a spray dryer to obtain solid silicon quantum dots.

[0056] After detection and calculation, the silicon quantum dots of this embodiment have a quantum ...

Embodiment 2

[0058] The method for synthesizing water-soluble silicon quantum dots by hydrothermal method with ureapropyltriethoxysilane as silicon source, its specific steps are as follows:

[0059] (1) Dissolve sodium citrate in deionized water under the protection of argon, and then add ureapropyltriethoxysilane to control the silicon source: sodium citrate molar ratio = 1:0.5, among which, ureapropyltriethoxysilane The concentration of ethoxysilane in water is 44mmol / L, and the concentration of sodium citrate in water is 22mmol / L. And adjust its pH=8, transfer the stirred and mixed solution into an autoclave and heat it to 200° C., and react for 3 hours to obtain a quantum dot solution.

[0060] (2) Mix the obtained silicon quantum dot solution with ethanol evenly at the ratio of quantum dots:ethanol=1:2. Centrifuge at 8000r / min for 5min, remove the supernatant, and dry the resulting precipitate in a vacuum to obtain solid silicon quantum dots.

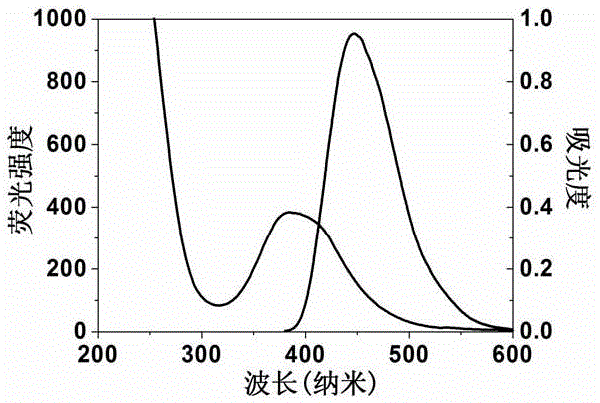

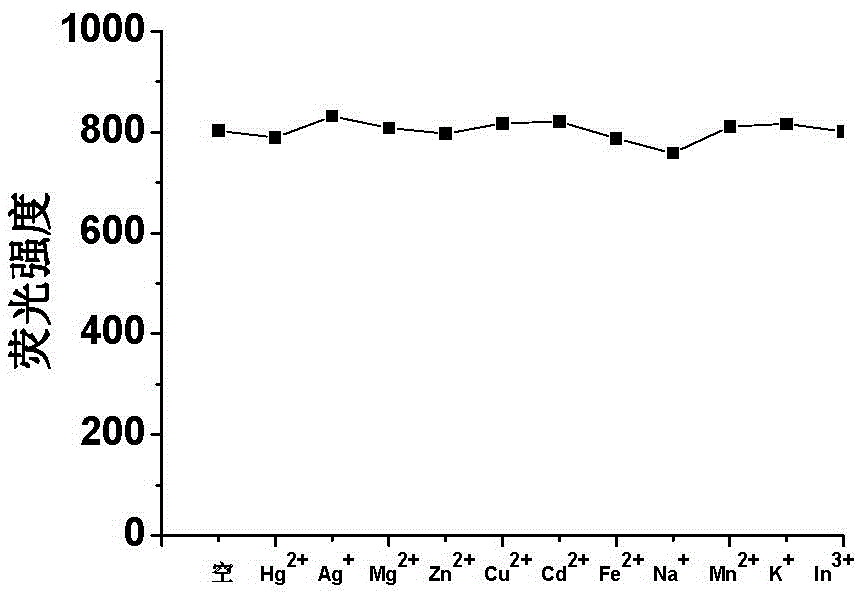

[0061] The ultraviolet absorption spe...

Embodiment 3

[0075] The method for synthesizing water-soluble silicon quantum dots by microwave method with ureapropyltrimethoxysilane as silicon source, its specific steps are as follows:

[0076] (1) Dissolve sodium citrate in deionized water under the protection of argon, and then add ureapropyltrimethoxysilane, silicon source: sodium citrate molar ratio = 1:0.4, among them, ureapropyltrimethoxysilane The concentration of silane in water is 60mmol / L, and the concentration of sodium citrate in water is 24mmol / L. And adjust its pH=10, then transfer the uniformly mixed solution into a microwave reactor and heat it to 180°C, and react for 15 minutes to obtain a silicon quantum dot solution.

[0077] (2) Mix the obtained silicon quantum dot solution with acetonitrile evenly at the ratio of quantum dots:acetonitrile=1:4. Centrifuge at 5000 r / min for 15 min, remove the supernatant, and freeze-dry the obtained precipitate to obtain solid silicon quantum dots.

[0078] Measure the XPS of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com