Low-temperature selective catalytic reduction denitration catalyst and preparation method thereof

A denitrification catalyst and selective technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of reducing catalyst service life, catalyst bed wear, low temperature Insufficient activity and other problems, to achieve the effect of improving surface properties, improving dispersion, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

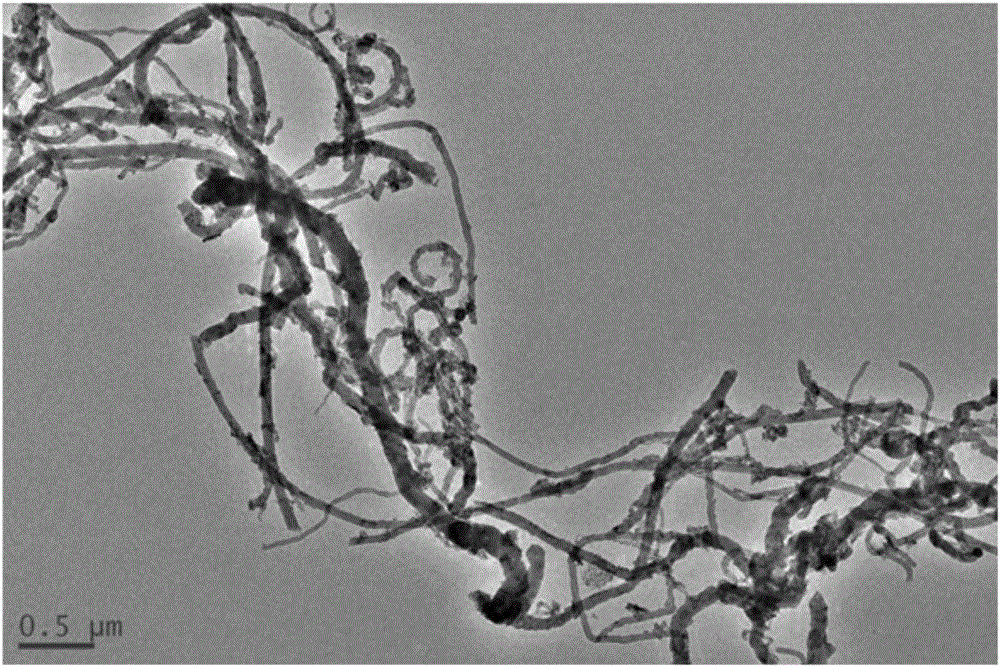

[0018] The present invention uses multi-walled carbon nanotubes as the carrier, FeO x As a cocatalyst, MnO x As an active component, a low-temperature flue gas denitrification catalyst based on carbon nanotubes is obtained. The preparation method is to firstly treat the carrier with nitric acid vapor, and then adopt the equal volume impregnation method to prepare the catalyst, which specifically includes the following steps: 1) firstly, pretreat the multi-walled carbon nanotubes, use nitric acid vapor to treat, then wash with water, and wash with alcohol , drying to obtain pretreated multi-walled carbon nanotubes; 2) adding the pretreated multi-walled carbon nanotubes obtained in step 1) into a mixed solution of manganese acetate and ferric nitrate, and ultrasonically treating them for 30-180min, so that Manganese acetate and ferric nitrate are uniformly dispersed in the solvent, and are impregnated with equal volumes for 10-48 hours; 3) After drying the mixture obtained in s...

Embodiment 1

[0023] Put 5ml of nitric acid aqueous solution (3mol / L) in a 50ml high-temperature hydrothermal kettle, place about 1g of carbon nanotubes on the upper part of a sand core crucible, place the crucible in a high-temperature hydrothermal kettle, and finally place the hydrothermal kettle in an oven , the oven temperature was set at 180°C, and after 5 hours, the hydrothermal kettle was cooled to room temperature, and the carbon nanotubes were taken out, washed with water and alcohol, and dried at 80°C for 5 hours to obtain modified multi-walled carbon nanotubes. Then the MnOx-FeOx / MWCNTs catalyst was prepared by equal volume impregnation method. Weighed 0.31g manganese acetate and 0.433g ferric nitrate nonahydrate to prepare 40ml solutions respectively, added to the pretreated MWCNTs, ultrasonically dispersed for 1h, and soaked at room temperature for about 12h . After the mixture was dried at 80°C, it was calcined in a tube furnace at 400°C for 2h under a nitrogen atmosphere. Fina...

Embodiment 2

[0025] Put 10ml of nitric acid aqueous solution (3mol / L) in a 50ml high-temperature hydrothermal kettle, place about 1g of carbon nanotubes on the upper part of a sand core crucible, place the crucible in a high-temperature hydrothermal kettle, and finally place the hydrothermal kettle in an oven , the oven temperature was set at 150°C, and after 5 hours, the hydrothermal kettle was cooled to room temperature, and the carbon nanotubes were taken out, washed with water and alcohol, and dried at 80°C for 5 hours to obtain modified multi-walled carbon nanotubes. Then the MnOx-FeOx / MWCNTs catalyst was prepared by the equal volume impregnation method. Weighed 0.155g manganese acetate and 0.361g ferric nitrate nonahydrate to prepare 40ml solutions respectively, added to the pretreated MWCNTs, ultrasonically dispersed for 1h, and soaked at room temperature for about 12h .After the mixture was dried at 80°C, it was calcined in a tube furnace at 400°C for 2h under a nitrogen atmosphere....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com