A kind of preparation method of agglomerated sintering type thermal spraying tungsten powder

A thermal spraying, tungsten powder technology, applied in coating, melting spraying, metal material coating process and other directions, can solve the problem that it is not suitable for the industrial production of thermal spraying tungsten powder, it is difficult to realize industrial production and application, the particle size range is difficult to control and Adjustment and other issues to achieve the effect of controllable particle size distribution, high sphericity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

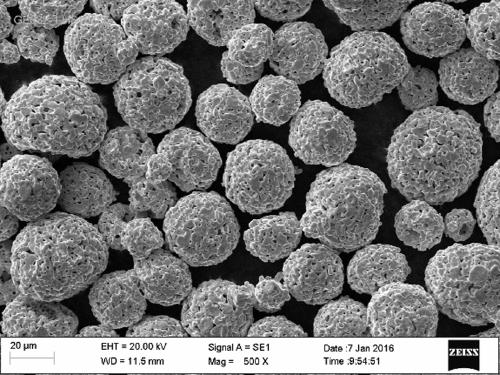

[0024] A preparation method of agglomerated sintering type thermal spraying tungsten powder, comprising the following steps:

[0025] Step 1. Select tungsten powder with a Fischer particle size of 0.8-30 μm as a raw material and set aside;

[0026] Step 2. Weigh polyvinyl alcohol, polyethylene glycol, polyvinylpyrrolidone and deionized water and mix them uniformly to prepare a forming agent solution for future use, wherein polyvinyl alcohol accounts for 0-3% of the mass of the forming agent solution, Polyethylene glycol accounts for 0-3% of the mass of the forming agent solution, polyvinylpyrrolidone accounts for 10-25% of the mass of the forming agent solution, and deionized water accounts for 75-90% of the mass of the forming agent solution;

[0027] Step 3. Put the deionized water, the tungsten powder weighed in step 1 and the forming agent solution weighed in step 2 into the ball mill according to the mass ratio (10-20%): 1: (3-10%) for ball milling activation , after the...

Embodiment 1

[0034] A preparation method of agglomerated sintering type thermal spraying tungsten powder, comprising the following steps:

[0035] Step 1. Select tungsten powder with a Fischer particle size of 3 μm as a raw material and set aside;

[0036] Step 2. Weigh polyvinyl alcohol, polyethylene glycol, polyvinylpyrrolidone and deionized water and mix them uniformly to form a forming agent solution for subsequent use. Wherein, polyvinyl alcohol accounts for 1.64% of the mass of the forming agent solution, polyethylene Pyrrolidone accounts for 16.39% of the quality of the forming agent solution, and deionized water accounts for 81.97% of the quality of the forming agent solution;

[0037] Step 3. Put the deionized water, the tungsten powder weighed in step 1 and the forming agent solution weighed in step 2 into a ball mill according to the mass ratio of 14%: 1:6% to activate the ball mill. After the ball mill is uniform, the tungsten powder suspension slurry, spare;

[0038] Step 4....

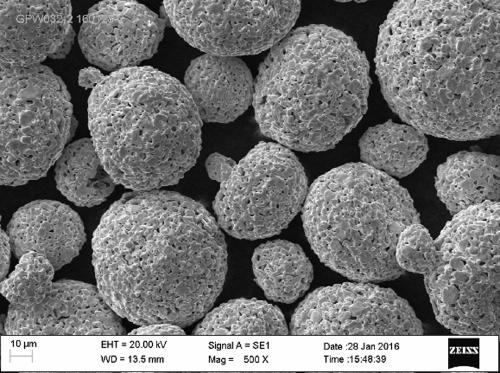

Embodiment 2

[0045] A preparation method of agglomerated sintering type thermal spraying tungsten powder, comprising the following steps:

[0046] Step 1. Select tungsten powder with a Fischer grain size of 1 μm as a raw material and set it aside;

[0047] Step 2: Take polyvinyl alcohol, polyethylene glycol, polyvinylpyrrolidone and deionized water and mix them uniformly to prepare a forming agent solution for subsequent use, wherein polyethylene glycol accounts for 2.5% of the mass of the forming agent solution, poly Vinylpyrrolidone accounts for 12.5% of the quality of the forming agent solution, and deionized water accounts for 85% of the quality of the forming agent solution;

[0048] Step 3. Put the deionized water, the tungsten powder weighed in step 1 and the forming agent solution weighed in step 2 into a ball mill according to the mass ratio of 14%: 1:6% to activate the ball mill. After the ball mill is uniform, the tungsten powder suspension slurry, spare;

[0049] Step 4. Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com