Hydrophobic heat-resistant silicone modified polyester resin and preparation method thereof

A technology for modifying polyester and polyester resin, applied in the field of chemical synthesis of new materials, can solve the problems of complex process, limited reaction degree, poor environmental protection, etc., and achieve low surface energy, good anti-fouling property, excellent hydrophobicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

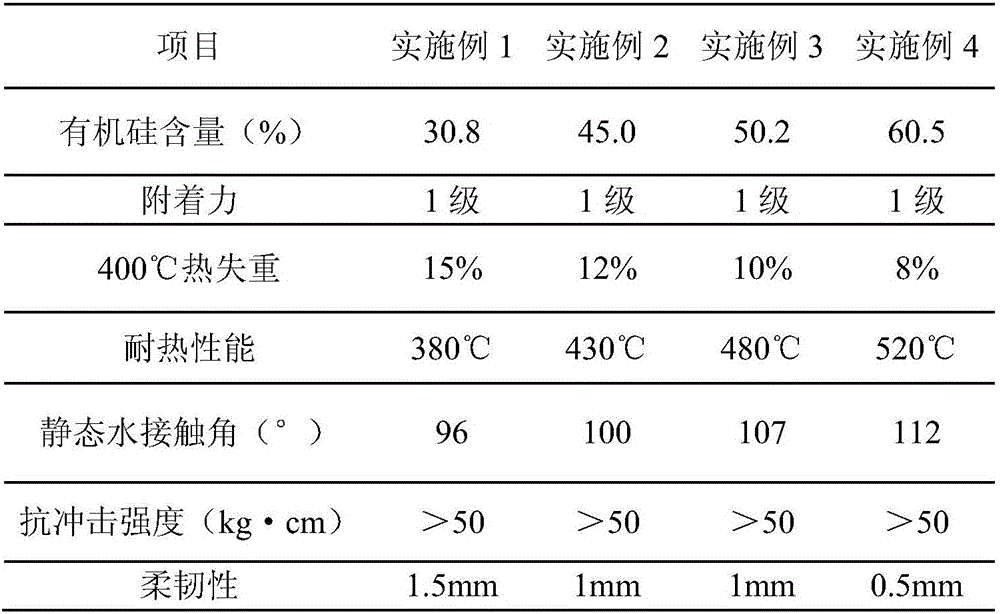

Examples

preparation example Construction

[0043] The invention provides a hydrophobic and heat-resistant silicone-modified polyester resin and a preparation method thereof. Specifically, the hydrophobic and heat-resistant silicone-modified polyester resin is made of the following components in parts by weight:

[0044] 3-8 parts of dihydric alcohol,

[0045] Trihydric alcohol 100-120 parts,

[0046] 60-120 parts of dibasic acid,

[0047] Silicone intermediate 100-250 parts,

[0048] Catalyst 0.5-1 part,

[0049] With water agent 5-10 parts,

[0050] 160-240 parts of organic solvent;

[0051] Wherein, the organosilicon intermediate has a weight average molecular weight of 800-2000, contains 3-20% of hydroxyl groups and 2.5-15% of methoxy groups or ethoxy groups.

[0052] The present invention obtains a hydroxyl-terminated saturated polyester resin through the copolymerization of A2 monomers (diacids) and B3 monomers (trihydric alcohols) through multifunctionality monomers, and the hydroxyl-terminated saturated polye...

Embodiment 1

[0071] A method for preparing a hydrophobic heat-resistant silicone-modified polyester resin, comprising the following steps:

[0072] 1) Preparation of hydroxyl-terminated saturated polyester resin: Add 5 parts by weight of neopentyl glycol and 120 parts by weight of trimethylol in a reaction device equipped with a nitrogen gas feed device, a mechanical stirrer, a thermometer, a reflux condenser, and a water separator Propane, heat up to 120 °C, feed nitrogen and start stirring, keep warm for 30 minutes, after the material melts, add 100 parts by weight of isophthalic acid and 5 parts by weight of xylene, heat up to 140 °C, keep warm for 1 hour, then heat up to 160 ℃, heat for 1 hour, heat up to 190°C, heat for 2 hours, heat up to 210°C, heat for 1-2 hours, after the acid value is less than 10mgKOH / g resin, cool down to 130°C, add 100 parts by weight of propylene glycol methyl ether acetate to dilute , to obtain a hydroxyl-terminated saturated polyester resin;

[0073] 2) Si...

Embodiment 2

[0075] 1) Preparation of hydroxyl-terminated saturated polyester resin: Add 8 parts by weight of 1,4-cyclohexanedimethanol and 100 parts by weight of trimethylolpropane, heat up to 120°C, blow in nitrogen and start stirring, keep warm for 15 minutes, after the material is melted, add 60 parts by weight of isophthalic acid, 20 parts by weight of 1,4-cyclohexanedicarboxylic acid With water agent, heat up to 150°C, heat up for 0.5h, heat up to 170°C, heat up for 0.5h, heat up to 200°C, heat up for 1h, heat up to 220°C, heat up for 1-2h, until the acid value is less than 10mgKOH / After g of resin, the temperature was lowered to 150° C., and 120 parts by weight of dipropylene glycol butyl ether was added for dilution to obtain a hydroxyl-terminated saturated polyester resin product.

[0076] 2) Organosilicon modification: In the reaction device equipped with a nitrogen feed device, a mechanical stirrer, a thermometer, a reflux condenser, and a water separator, add the polyester res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com