Oxygen-doped nitrogen carbide-precious metal composite catalyst, and preparation method and application thereof

A carbonized nitrogen and oxygen doping technology, which is applied in the preparation of amino compounds, organic compounds, amino hydroxyl compounds, etc., to achieve the effects of inhibiting recombination, improving absorption, and improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

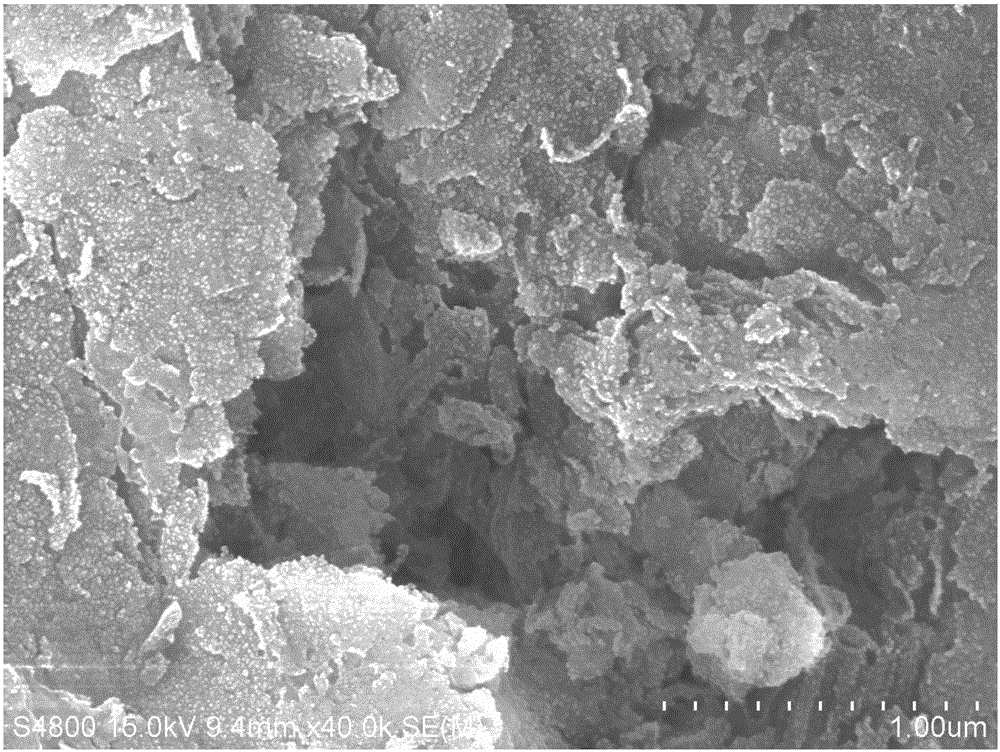

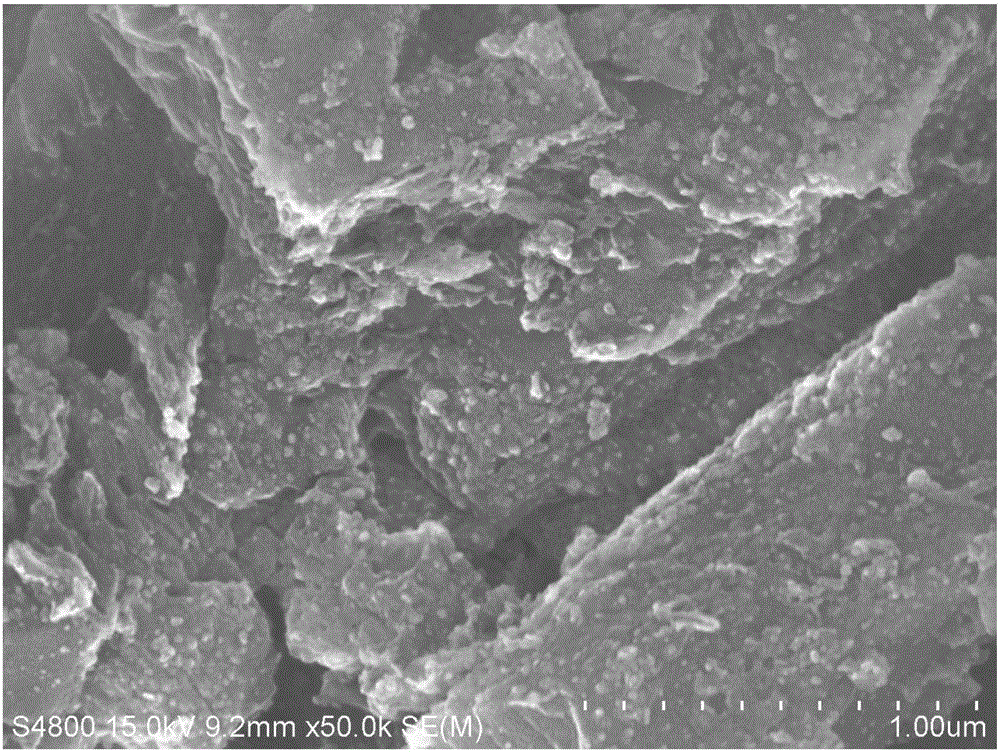

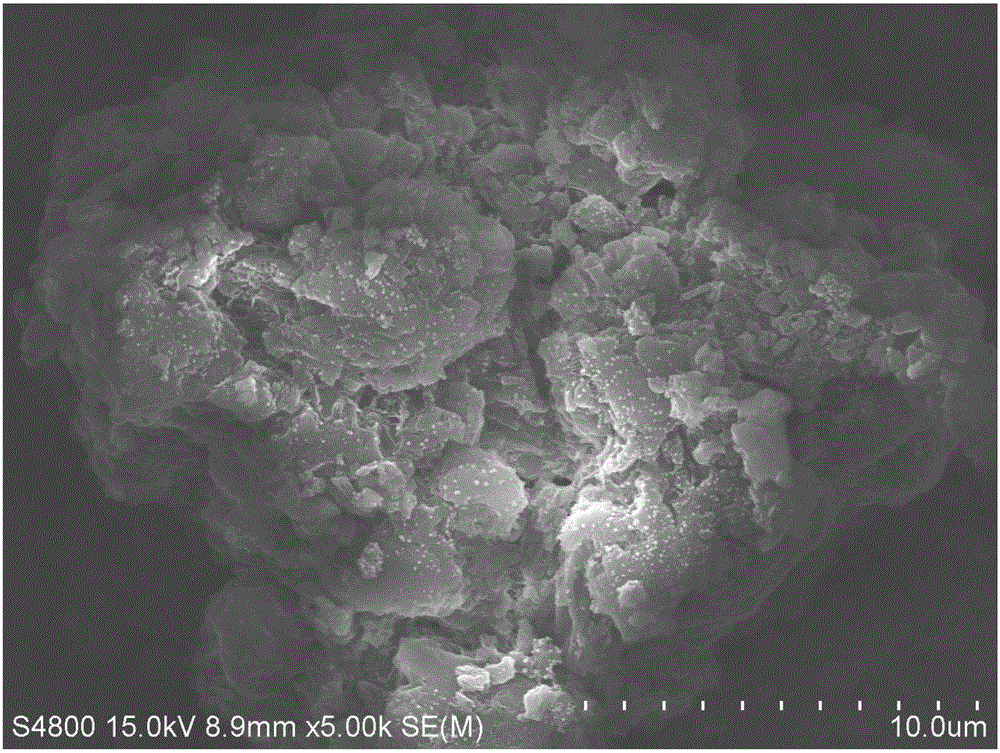

Image

Examples

Embodiment 1

[0038] A preparation method of oxygen-doped nitrogen carbide-noble metal composite photocatalyst, comprising the following steps:

[0039](1) Synthesis of carbonized nitrogen and preparation of suspension: Weigh 10 grams of melamine and place it in a muffle furnace, calcinate at 600° C. for 5 hours, cool to room temperature, and obtain yellow carbonized nitrogen solid powder after sufficient grinding. Then take 200 mg of nitrogen carbide solid powder and ultrasonically disperse it in 200 milliliters of methanol solvent to obtain a 1 mg / ml nitrogen carbide suspension for use;

[0040] (2) Synthesis of oxygen-doped carbonized nitrogen and preparation of the suspension: take 100 ml of the suspension of the above-mentioned carbonized nitrogen and put it into a reaction kettle, add 200 ml of hydrogen peroxide with a mass fraction of 20% and stir thoroughly, then heat the mixture under 120° C. React for 6 hours, cool naturally to room temperature, and centrifuge at high speed, wash ...

Embodiment 2

[0045] A preparation method of oxygen-doped nitrogen carbide-noble metal composite photocatalyst, comprising the following steps:

[0046] (1) Synthesis of carbonized nitrogen and preparation of suspension: Weigh 15 grams of dipolycyanamide and place it in a muffle furnace, calcinate at 650°C for 8 hours, cool to room temperature, and obtain yellow carbonized nitrogen after thorough grinding Solid powder, then take 100 mg of nitrogen carbide solid powder and ultrasonically disperse it in 200 ml of ethanol solvent to obtain a 0.5 mg / ml nitrogen carbide suspension for use;

[0047] (2) Synthesis of oxygen-doped carbonized nitrogen and preparation of the suspension: take 100 ml of the suspension of the above-mentioned carbonized nitrogen and put it into a reaction kettle, add 80 ml of hydrogen peroxide with a mass fraction of 30% and stir thoroughly, then heat the mixture under 180° C. React for 4 hours, cool naturally to room temperature, and centrifuge at high speed, wash the p...

Embodiment 3

[0052] A preparation method of oxygen-doped nitrogen carbide-noble metal composite photocatalyst, comprising the following steps:

[0053] (1) Synthesis of carbonized nitrogen and preparation of suspension: Weigh 20 grams of urea and place it in a muffle furnace, calcinate at 550° C. for 8 hours, cool to room temperature, and obtain yellow carbonized nitrogen solid powder after sufficient grinding. Then take 300 mg of nitrogen carbide solid powder and ultrasonically disperse it in 100 milliliters of n-propanol solvent to obtain a 3 mg / ml nitrogen carbide suspension for use;

[0054] (2) Synthesis of oxygen-doped carbonized nitrogen and preparation of the suspension: take 50 ml of the suspension of the above-mentioned carbonized nitrogen and put it into a reaction kettle, add 100 ml of hydrogen peroxide with a mass fraction of 15% and stir thoroughly, then heat the mixture under 160° C. React for 8 hours, naturally cool to room temperature, high-speed centrifugation, wash the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com