Bipolar membrane electro-catalysis treatment device

A bipolar membrane and treatment device technology, applied in electrochemical water/sewage treatment, water/sewage treatment, chemical/physical process, etc., can solve the problems of large current, large energy consumption, and shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

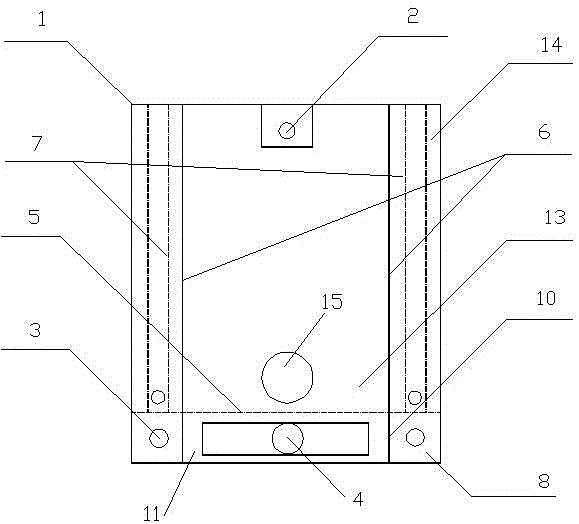

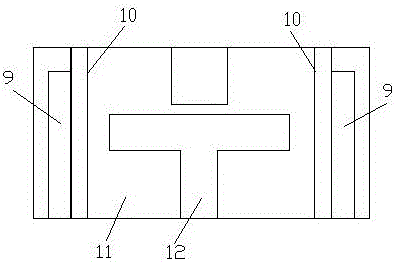

[0035] Embodiment 1: A bipolar membrane electrocatalytic treatment device, including a housing (1), a water outlet weir (2) located above the housing (1), a water inlet (3) located below the housing (1), and an air inlet (4), the bottom of the housing (1) is provided with a No. 1 isolation plate (5) and a No. 2 isolation plate (6) on both sides. An ion-selective membrane (7) is provided between them, and the innermost side of the housing (1) is an electrocatalytic plate (14); the bottom No. 1 separator (5) inside the housing (1) is connected to the (1) There is a water distribution chamber (8) and an air distribution chamber (11) between the bottom, and the area above the No. 1 isolation plate (5) is the reaction area (13). The ion-selective membrane (7) is a monolithic ion-selective membrane, and the polarity of the monolithic ion-selective membranes on both sides inside the casing (1) is opposite, and is consistent with the polarity of the power supply connected to the elect...

Embodiment 2

[0037] Embodiment 2: the carbon electrocatalyst catalyst comprises the following preparation steps:

[0038] (1) Raw material configuration:

[0039] Toner 240kg;

[0041] Iron powder 32 kg;

[0042] Manganese powder 60 kg;

[0043] Aluminum powder 24 kg;

[0044] Magnesium powder 2kg;

[0045] Titanium powder 2kg;

[0046] Phosphorus pentoxide 2kg;

[0047] Silica fume 16kg;

[0049] Weigh the raw materials in proportion and put them into the mixer for wet mixing;

[0050] (2) Grind the raw materials to control the final particle size to ≤3um. The raw material powder is mixed with methane-nitrogen ratio of 2:1 and heated to 170°C in the absence of air. Weigh 200kg of alcohol and 20kg of high-temperature modified asphalt, add high-temperature modified asphalt to the alcohol, and add 0.4kg of anti-settling agent polyglycol ether and 0.4kg of carbonization accelerator carbodiimide, stir evenly, and make a mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com