Preparation method and surface hydrophilicity of implant nanotube array through secondary anode and reaming on the surface of implant material

A nanotube array, implant technology, applied in surface reaction electrolytic coatings, electrolytic coatings, coatings, etc., can solve the problems of weak osteogenic ability, no biological activity, loose and detached implant dentures, etc. Uniform distribution, good electrochemical stability, the effect of optimizing surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Select pure titanium to process it into a dental implant matrix, polish it to a mirror surface in water sequentially with silicon carbide sandpaper from 400 mesh to 8000 mesh, then use acetone, absolute ethanol, and deionized water to ultrasonically clean for 10 minutes each, and then dry it. use;

[0029] (2) Electrolyte preparation: the volume fraction is 0.5% HF+99.5% deionized water;

[0030] (3) Chemical polishing: the volume fraction is (2%-8%) HF+(10%-20%) nitric acid+(72%-88%) distilled water, the polishing time is 5 minutes, absolute ethanol, deionized water ultrasonic Wash for 5 minutes each, then blow dry for later use;

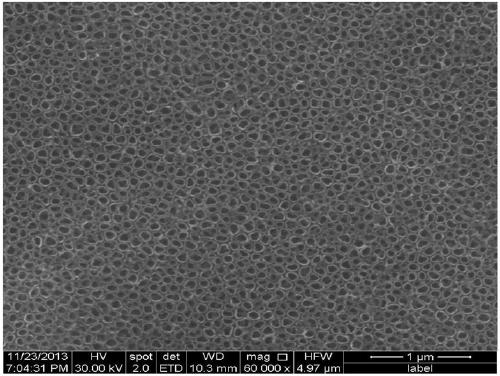

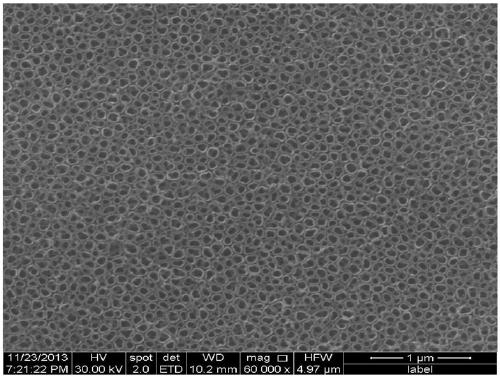

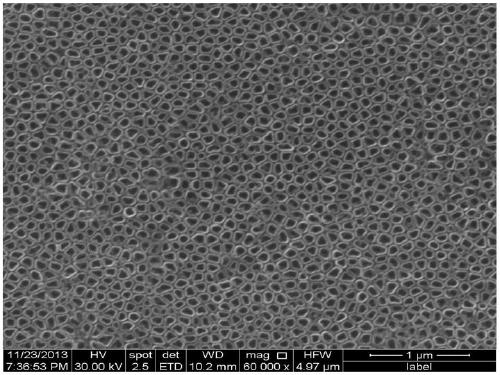

[0031] (4) Primary anode: titanium implant matrix is the anode, graphite is the cathode, the DC stable voltage is 20V, the time is 1 hour, the speed of the magnetic stirrer is 350 rpm, the distance between the two poles is 8 cm, and the temperature is room temperature. Wash with absolute ethanol and deionized water, dry (see attached...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com