Nitrogen-rich hollow carbon sphere/sulfur composite positive electrode material for lithium-sulfur battery and preparation method of nitrogen-rich hollow carbon sphere/sulfur composite positive electrode material

A composite positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of capacity attenuation, low Coulombic efficiency, etc., and achieve the effects of improved conductivity, high capacity, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

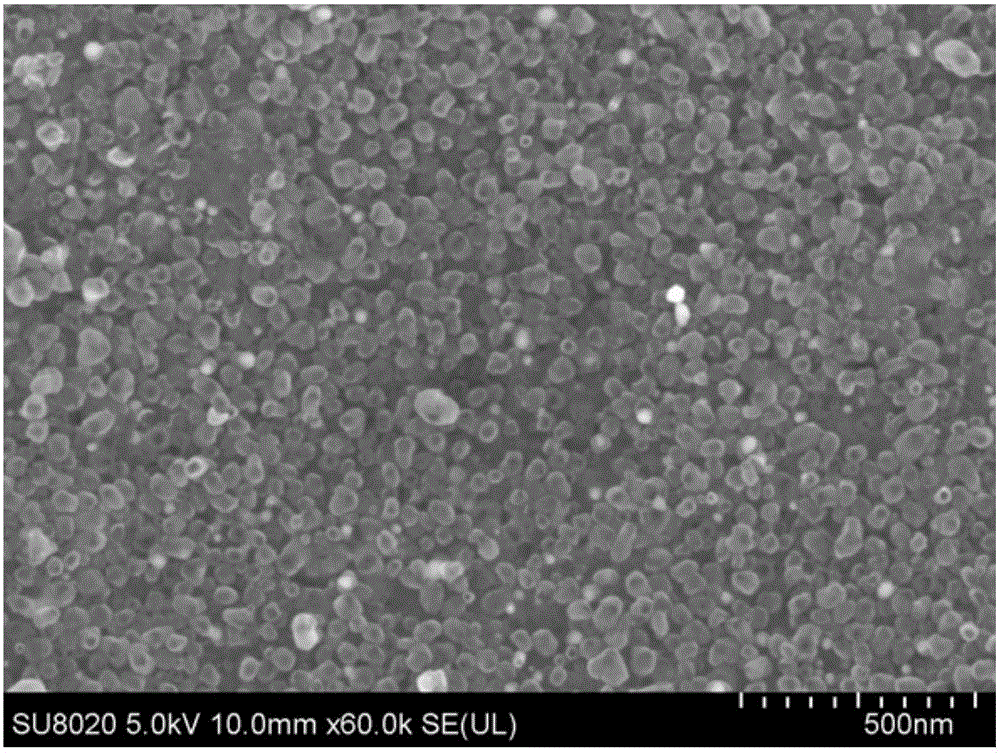

[0027] Melamine and Co(CH 3 COO) 2 4H 2 O weighed according to the mass ratio of 1:1, first stirred with a stirrer for 15 minutes at a low speed, and then stirred at a high speed for 15 minutes to obtain a uniform pink powder, which was placed in a crucible and transferred to a tubular electric furnace. 400°C for 2h, 500°C for 2h, 650°C for 2h, heating rate 2°C / min, soak and wash the product in 150ml HCL solution with a mass fraction of 10% for 24h, and use a pore size of 20-50μm The hydrophilic membrane was suction-filtered and washed with deionized water until neutral, and dried at 80°C for 12 hours to obtain nitrogen-enriched hollow carbon spheres.

[0028] Mix 1g of nitrogen-enriched hollow carbon spheres with 1.5g of elemental sulfur, add ethanol, and then ball mill for 120min at a speed of 400r / min. After drying, transfer to a stainless steel reactor for heating at 155˚C for 12h. Nitrogen-rich hollow carbon sphere / sulfur composite cathode material.

[0029] Mix the n...

Embodiment 2

[0031] Melamine and Co(CH 3 COO) 2 4H 2 O weighed according to the mass ratio of 1:2, first stirred with a stirrer at low speed for 20 minutes, then at high speed for 20 minutes to obtain a uniform pink powder, put the uniform pink powder in a crucible and transfer it to a tubular electric furnace, nitrogen atmosphere 300°C for 1h, 400°C for 1h, 520°C for 2h, 650°C for 2h, heating rate 1°C / min, soak the product in 150ml HCL solution with a mass fraction of 10% for 24h, then use A hydrophilic filter membrane with a pore size of 20-50 μm is sucked and washed with deionized water until neutral, and dried at 70° C. for 24 hours to obtain nitrogen-enriched hollow carbon spheres.

[0032] Mix 1g of nitrogen-enriched hollow carbon spheres with 1.5g of elemental sulfur, add carbon disulfide, and then ball mill for 60min at a ball mill speed of 500r / min. After drying, transfer to a stainless steel reactor for heating at 160˚C for 6h to obtain Nitrogen-rich hollow carbon sphere / sulfu...

Embodiment 3

[0035] Melamine and Co(CH 3 COO) 2 4H 2 O is weighed according to the mass ratio of 1:2, first stirred with a stirrer at low speed for 30 minutes, and then at high speed for 30 minutes, and the obtained uniform pink powder was placed in a crucible and transferred to a tubular electric furnace. Incubate at ˚C for 2 hours, at 500˚C for 2 hours, at 750˚C for 2 hours, and at a heating rate of 3˚C / min. After soaking the product in 200ml of 10% HCL solution for 24 hours, filter it through a hydrophilic filter with a pore size of 20-50μm The membrane was suction-filtered and washed with deionized water until neutral, and dried at 100°C for 8 hours to obtain nitrogen-enriched hollow carbon spheres.

[0036] Mix 1g of nitrogen-enriched hollow carbon spheres with 5g of sodium sulfide, ultrasonically disperse them in 100ml of water, add 20ml of 1% HCL solution and stir for 6 hours, then transfer to a stainless steel reaction kettle for heating at 160˚ after centrifugal separation and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com