Silk fibroin-alginate composite film, as well as preparation method and application thereof

A technology of silk fibroin and alginate, applied in the field of composite materials, can solve the problems of easy loss of small counterion molecules, unstable membrane dissolution, insufficient strength and flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

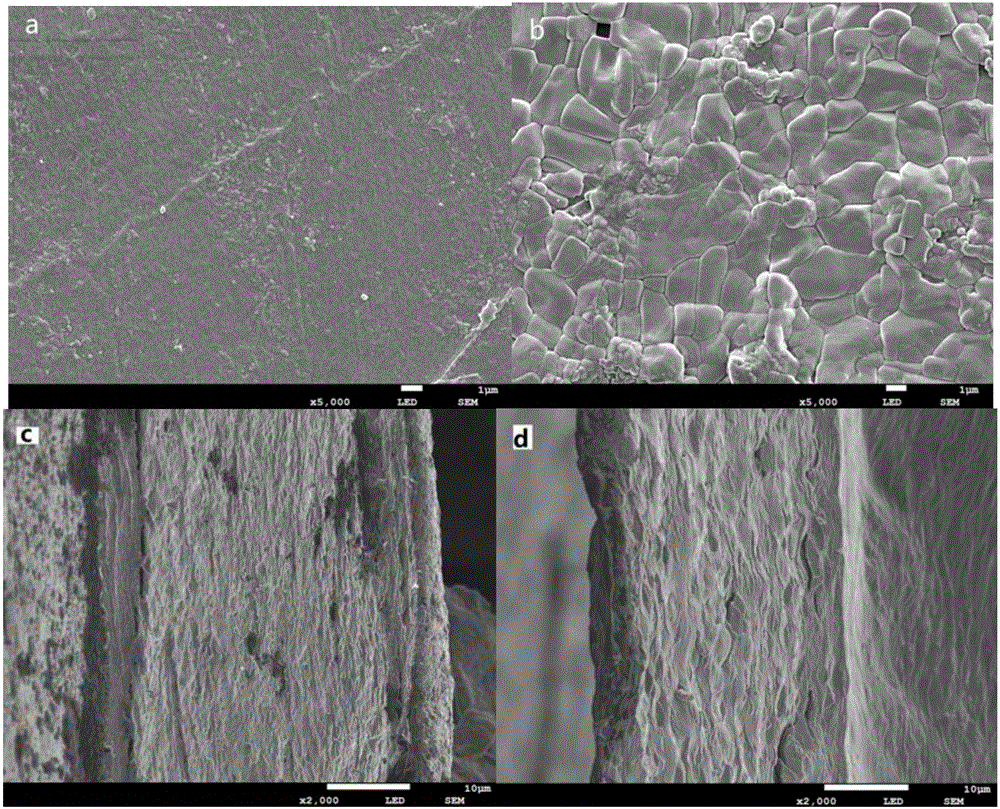

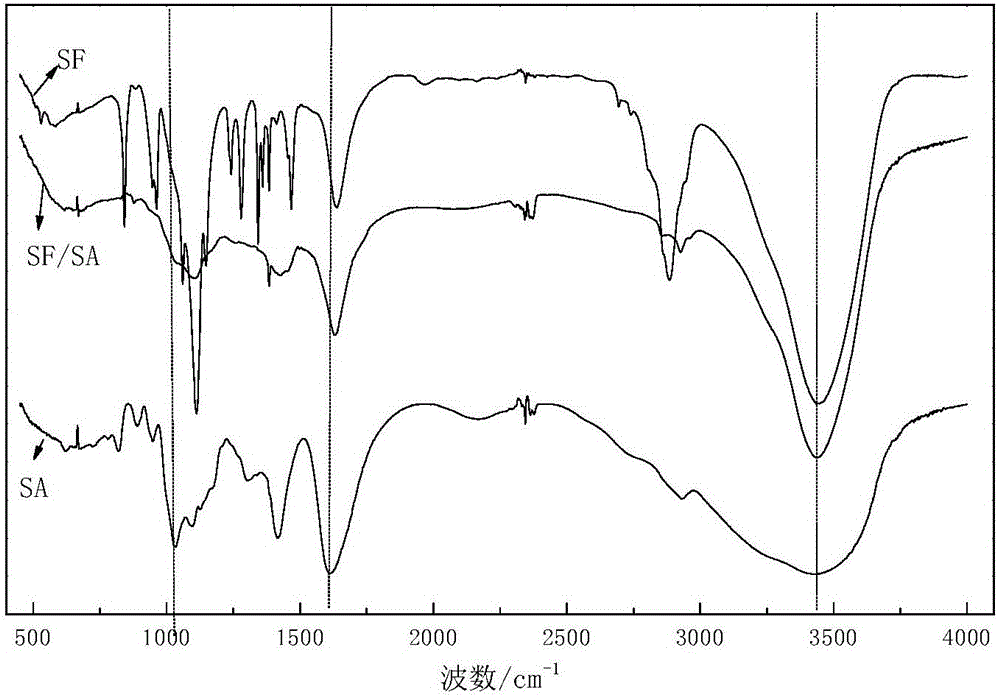

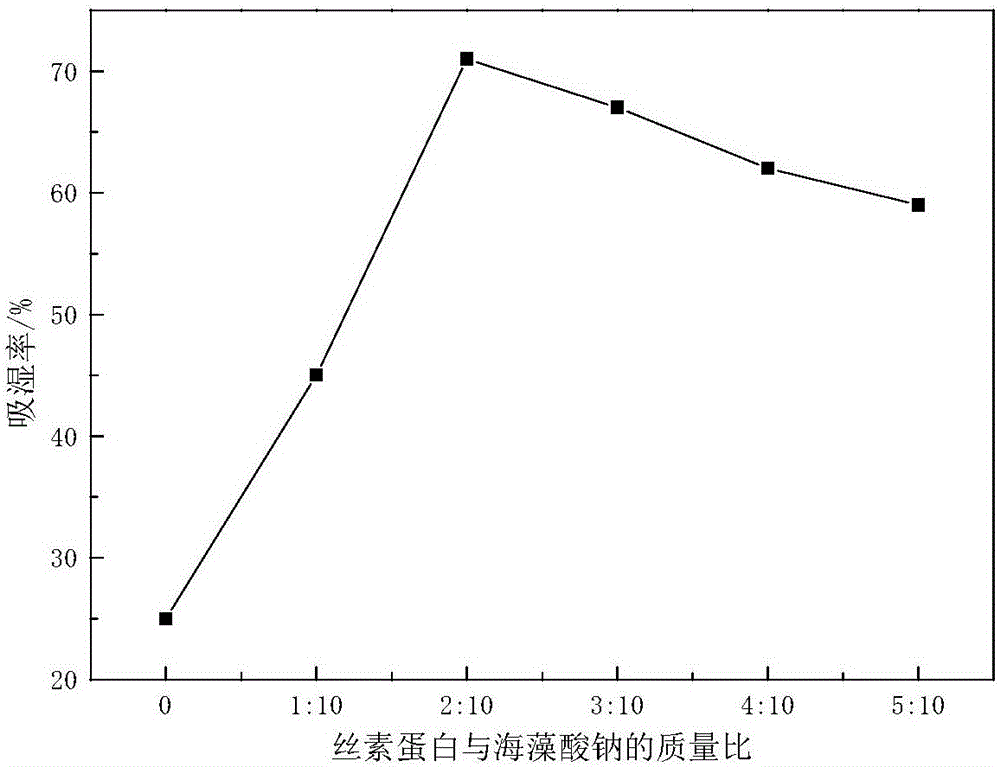

[0027] First, degumming, centrifugation, filtration, dialysis, and concentration of the shredded silk cocoons were performed to obtain a silk fibroin solution with a mass fraction of 5%. In a hot water bath at 60°C, 2g of sodium alginate and 100ml of deionized water were used as raw materials. Use gentle stirring to configure sodium alginate aqueous solution; mix the aqueous solution containing 0.2g silk fibroin with the prepared sodium alginate aqueous solution evenly to obtain a silk fibroin-sodium alginate mixture, which is defoamed and left to stand for later use . The mixed solution is naturally spread on the glass plate by casting method, the solution thickness is 2mm, and the composite film is solidified with a calcium chloride aqueous solution with a mass fraction of 3%. The membrane is used as the standard, and then the calcium chloride on the surface of the membrane is washed with deionized water, and then dried naturally in a constant temperature and humidity chambe...

Embodiment 2

[0029] First, degumming, centrifugation, filtration, dialysis, and concentration of the shredded silk cocoons were performed to obtain a silk fibroin solution with a mass fraction of 5%. In a hot water bath at 60°C, 2g of sodium alginate and 100ml of deionized water were used as raw materials. Use gentle stirring to configure sodium alginate aqueous solution; mix the aqueous solution containing 0.4g silk fibroin with the prepared sodium alginate aqueous solution evenly to prepare silk fibroin-sodium alginate mixed solution, defoam and stand for backup use. The mixed solution is naturally spread on the glass plate by casting method, the solution thickness is 2mm, and the composite film is solidified with a calcium chloride aqueous solution with a mass fraction of 3%. The membrane shall prevail, and then be cleaned with deionized water until calcium chloride-free, and then dried naturally in a constant temperature and humidity chamber with a temperature of 50° C. and a relative ...

Embodiment 3

[0031] Same as Example 2, the difference is that the aqueous solution containing 0.6g silk fibroin is uniformly mixed with the prepared aqueous sodium alginate solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com