A kind of fly ash base polymer fireproof coating and preparation method thereof

A technology of fire-resistant coatings and fly ash, which is applied in cement production, etc., can solve the problems of high transportation costs, lack of market competitiveness, and complex production processes for two-component coatings, and achieve good durability, fast drying speed, and excellent preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

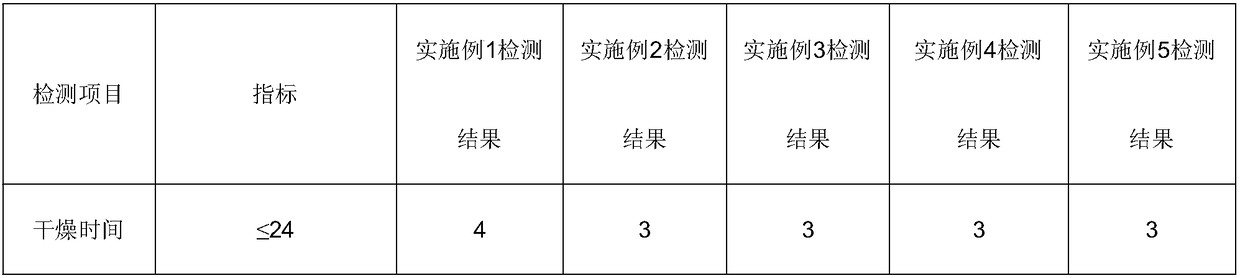

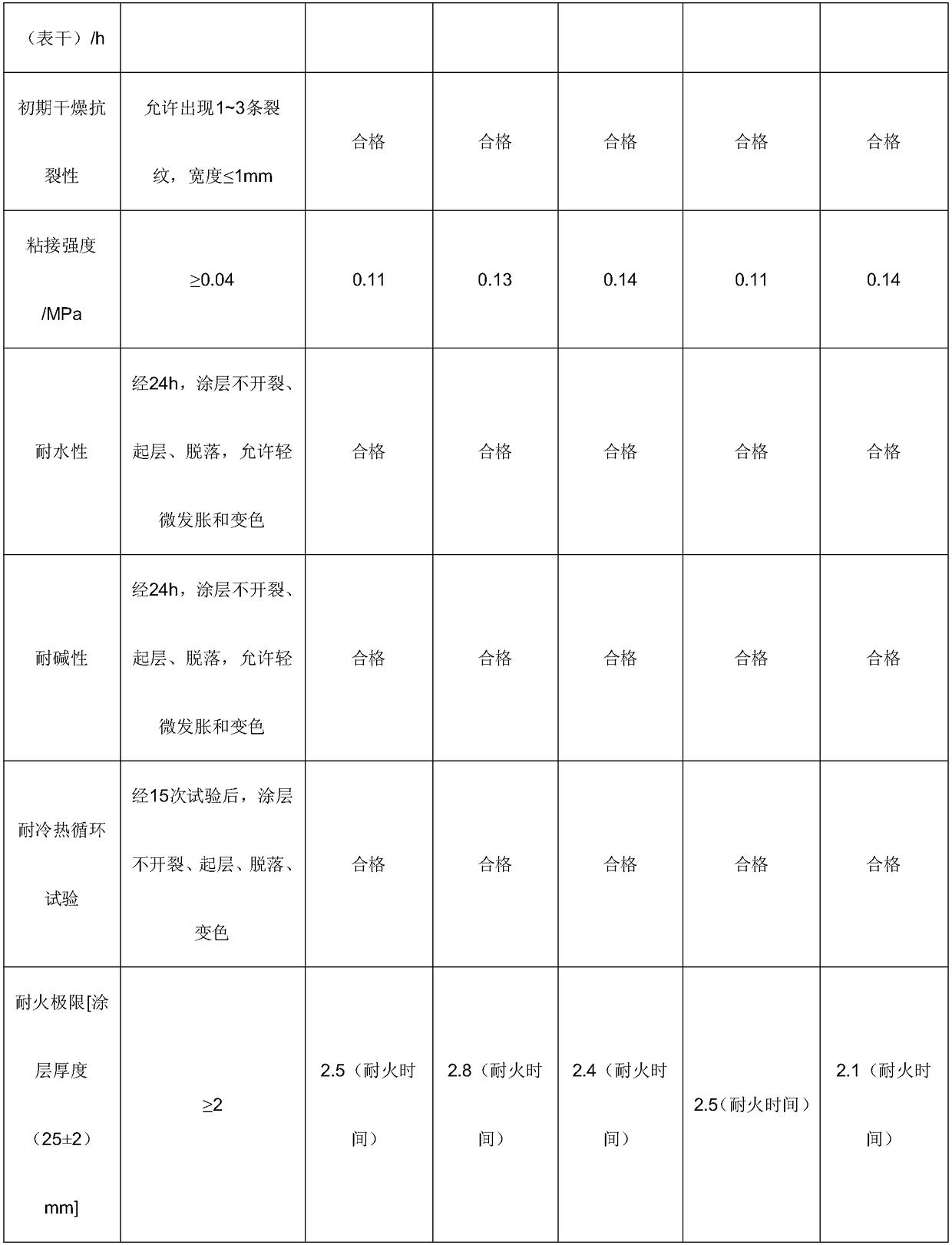

Examples

Embodiment 1

[0030] Prepare raw materials according to the following components and weight: modified water glass 30kg, fly ash 40kg, metakaolin 10kg, sodium hexametaphosphate 0.02kg, alkyl silicone oil 0.03kg, 800 mesh light calcium powder 20kg, aluminum hydroxide 0.5kg, Inorganic thickener 0.02kg, silicone acrylic emulsion 1.0kg, water 15kg.

[0031] Prepare the fly ash base polymer fire retardant coating according to the following steps:

[0032] (1) use sodium hydroxide to adjust the modulus of modified water glass to be 1.0, and the concentration is 30%;

[0033] (2) Mix the adjusted modified water glass with the mixture of fly ash and metakaolin, add water, dispersant, some defoamers, pigments and fillers, and flame retardant under the stirring condition of 1000r / min, and stir for 30 minutes;

[0034] (3) Add the polymer emulsion, thickener, and the remaining defoamer under the stirring condition of 600r / min, stir for 30min, and obtain the fireproof coating after the mixture is unifo...

Embodiment 2

[0036] Prepare raw materials according to the following components and weight: 35kg of modified water glass, 45kg of fly ash, 10kg of metakaolin, 0.02kg of sodium hexametaphosphate, 0.03kg of castor oil, 10kg of 900 mesh light calcium powder, 0.8kg of aluminum hydroxide, inorganic Thickener 0.02kg, silicone acrylic emulsion 1.0kg, water 15kg.

[0037] Prepare the fly ash base polymer fire retardant coating according to the following steps:

[0038] (1) use sodium hydroxide to adjust the modulus of modified water glass to be 1.1, and the concentration is 35%;

[0039] (2) Mix the adjusted modified water glass with fly ash and metakaolin mixture, add water, dispersant, some defoamers, pigments and fillers, and flame retardant under the stirring condition of 1200r / min, and stir for 35min;

[0040] (3) Add the polymer emulsion, thickener, and the remaining defoamer under the stirring condition of 700r / min, stir for 45min, and obtain the fireproof coating after the mixture is unif...

Embodiment 3

[0042] Prepare raw materials by following components and weight: modified water glass 35kg, fly ash 45kg, sodium hexametaphosphate 0.02kg, palm oil 0.03kg, 1000 mesh light calcium powder 20kg, melamine 0.5kg, organic thickener 0.02kg, Pure acrylic emulsion 1.5kg, water 15kg.

[0043] Prepare the fly ash base polymer fire retardant coating according to the following steps:

[0044] (1) use sodium hydroxide to adjust the modulus of modified water glass to be 1.1, and the concentration is 35%;

[0045] (2) Mix the adjusted modified water glass with the mixture of fly ash and metakaolin, add water, dispersant, some defoamers, pigments and fillers, and flame retardant under the stirring condition of 1300r / min, and stir for 40min;

[0046] (3) Add the polymer emulsion, thickener, and the remaining defoamer under the stirring condition of 800r / min, stir for 50min, and obtain the fireproof coating after the mixture is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com