Antibacterial and mildew-proof paint

An antibacterial, mildew proof and paint technology, applied in the field of paint, can solve the problems of poor antibacterial effect, fracture, reduced molecular weight and purity, etc., and achieves the effects of low output of acid-base wastewater, simple preparation process and high degree of deacetylation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

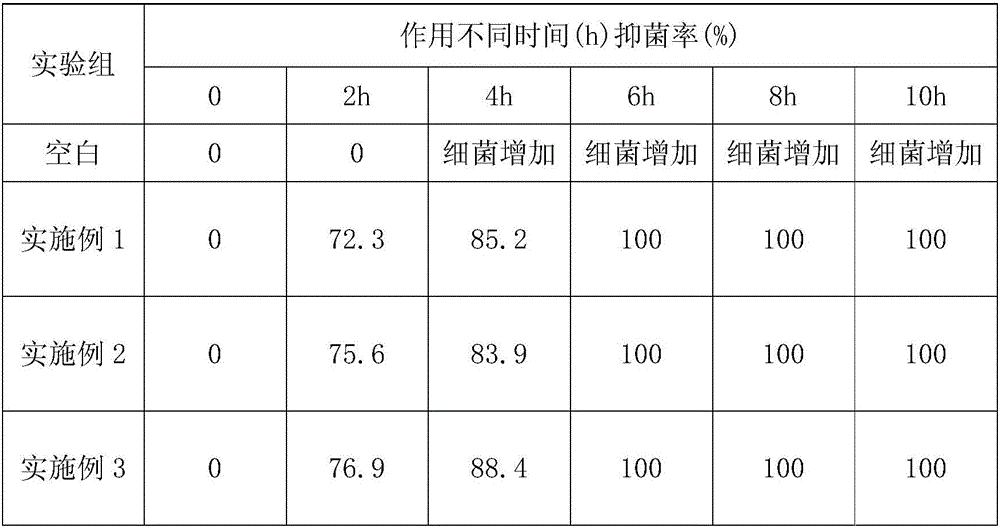

Examples

Embodiment 1

[0034] (1) Decalcification: After crushing 10g insect carapace, it is immersed in 200g diluted acid with a mass concentration of 10% at 50℃ for 4 hours, filtered, and the filter cake is washed 3-5 times and dried to obtain 7.2g decalcification Product A;

[0035] (2) Deproteinization: Put 7.2g decalcification product A, 0.09g trypsin, 0.09g papain, 0.18g alkaline lipase and 144g water in a three-necked flask, control the pH of the reaction solution to 7.5, and stir at 40°C After 3 hours of hydrolysis, filter, take the filter cake and wash and dry to obtain 4.3 g of deproteinized product B;

[0036] (3) Purification: Dissolve 4.3g of deproteinized product B, 28g of caproic acid, 22g of oxalic acid, 14g of pyridine and 0.43g of NaCl, stir and dissolve at 60°C for 3 hours, filter, and dry the filtrate under reduced pressure to remove the solvent. After washing with water to remove NaCl, and drying to obtain 3.2 g of chitin, the HPLC purity was 92.3%, the recovery rate was 29.54%, and...

Embodiment 2

[0042] (1) Decalcification: After crushing 10g insect carapace, it is immersed in 250g dilute acid with a mass concentration of 15% at 30℃ for 6 hours, filtered, and the filter cake is washed 3-5 times and dried to obtain 7.8g decalcification Product A;

[0043] (2) Deproteinization: Put 7.8g decalcification product A, 0.12g trypsin, 0.12g papain, 0.24g alkaline lipase and 78g water in a three-necked flask, control the pH of the reaction solution to 8, and stir at 50°C After 2.5 hours of hydrolysis, filter, take the filter cake and wash and dry to obtain 5.1 g of deproteinized product B;

[0044] (3) Purification: 5.1g deproteinized product B, 40g caproic acid, 32g oxalic acid, 20g pyridine and 1g MgSO 4 After stirring and dissolving at 70°C for 2 hours, filter, the filtrate was dried under reduced pressure to remove the solvent, and then washed with water to remove MgSO 4 , Dried to obtain 3.8g chitin, HPLC purity is 93.8%, recovery rate is 35.6%, ash content is 0.78%.

[0045] (4)...

Embodiment 3

[0049] (1) Decalcification: After crushing 10g insect carapace, it is immersed in 300g dilute acid with a mass concentration of 20% at 40℃ for 5 hours, filtered, and the filter cake is washed 3-5 times and dried to obtain 6.9g decalcification Product A;

[0050] (2) Deproteinization: Put 6.9g decalcification product A, 0.14g trypsin, 0.14g papain, 0.28g alkaline lipase and water in a three-necked flask, control the pH of the reaction solution to 8.5, and stir and hydrolyze at 55℃ After 2 hours, filter, take the filter cake, wash and dry to obtain 4.6 g of deproteinized product B;

[0051] (3) Purification: 4.6g deproteinized product B, 40g caproic acid, 32g oxalic acid, 20g pyridine and 1.4g Na 2 SO 4 After stirring and dissolving at 80°C for 1 hour, filter, the filtrate is dried under reduced pressure to remove the solvent, and then washed with water to remove Na 2 SO 4 , Dried to obtain 3.5g chitin, HPLC purity is 93.1%, recovery rate is 32.6%, ash content is 0.72%.

[0052] (4) D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com