Method for synthesizing anatase titanium dioxide and manganese dioxide nanocomposite through surfactant assisted electrodeposition and application of method

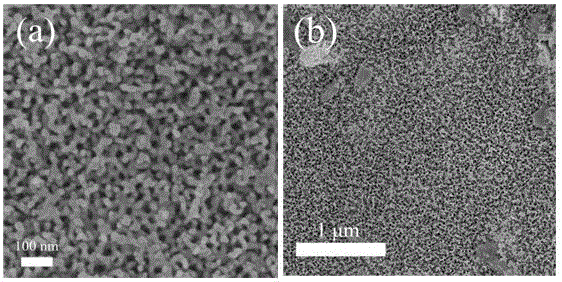

A nanocomposite material, surfactant technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, metal/metal oxide/metal hydroxide catalysts, etc. Long cycle, uneven product morphology and other problems, to achieve the effect of good stability and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

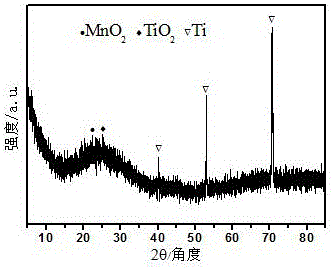

[0038] A preparation method for the synthesis of anatase titanium dioxide and manganese dioxide nanocomposites by surfactant-assisted electrodeposition, comprising the steps of:

[0039] (1) In a beaker, add 7.5 g of sodium dodecyl sulfate (SDS), 37.5 g of glycerol, and 10 mL of n-hexane, and stir well to obtain solution A;

[0040](2) In another beaker, add 2.5 g of manganese sulfate, 5 g of ammonium fluoride, 3 g of disodium ethylenediaminetetraacetic acid (disodium EDTA), appropriate amount of distilled water, stir well, and dilute to a 500 mL volumetric flask , to obtain solution B;

[0041] (3) Add solution B dropwise to solution A, and the formed mixed solution first goes through the process of turbidity to clarification, then turbidity, and clarification again, and the mixed solution formed during the second clarification is microemulsion C. The regulated power supply was adjusted to 2.5 V, the 2 × 3 cm titanium sheet was used as the anode, the 2 × 3 cm copper sheet wa...

Embodiment 2

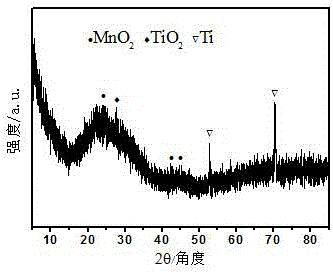

[0044] A preparation method for the synthesis of anatase titanium dioxide and manganese dioxide nanocomposites by surfactant-assisted electrodeposition, comprising the steps of:

[0045] (1) In a beaker, add 20 g of cetyltrimethylammonium bromide (CTAB), 100 g of glycerol, and 50 mL of n-hexane, and stir well to obtain solution A;

[0046] (2) In another beaker, add 2.5 g of manganese sulfate, 5 g of ammonium fluoride, 3 g of disodium ethylenediaminetetraacetic acid (disodium EDTA), appropriate amount of distilled water, stir well, and dilute to a 500 mL volumetric flask , to obtain solution B;

[0047] (3) Add solution B to solution A dropwise, the formed mixed solution first goes through the process of turbidity to clarification, then turbidity, and clarification again, and the mixed solution formed during the second clarification is microemulsion C. The regulated power supply was adjusted to 2.5 V, the 2 × 3 cm titanium sheet was used as the anode, the 2 × 3 cm copper shee...

Embodiment 3

[0050] A preparation method for the synthesis of anatase titanium dioxide and manganese dioxide nanocomposites by surfactant-assisted electrodeposition, comprising the steps of:

[0051] (1) In a beaker, add 10 g sodium dodecylbenzenesulfonate, 30 g n-butanol, and 40 mL n-heptane, and stir well to obtain solution A;

[0052] (2) In another beaker, add 2.5 g of manganese sulfate, 5 g of ammonium fluoride, 3 g of disodium ethylenediaminetetraacetic acid (disodium EDTA), appropriate amount of distilled water, stir well, and dilute to a 500 mL volumetric flask , to obtain solution B;

[0053] (3) Add solution B to solution A dropwise, the formed mixed solution first goes through the process of turbidity to clarification, then turbidity, and clarification again, and the mixed solution formed during the second clarification is microemulsion C. The regulated power supply was adjusted to 5 V, the 2 × 3 cm titanium sheet was used as the anode, the 2 × 3 cm copper sheet was used as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com