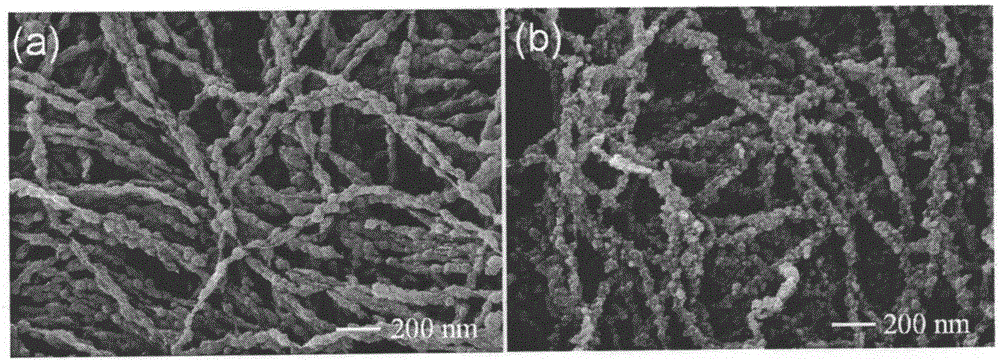

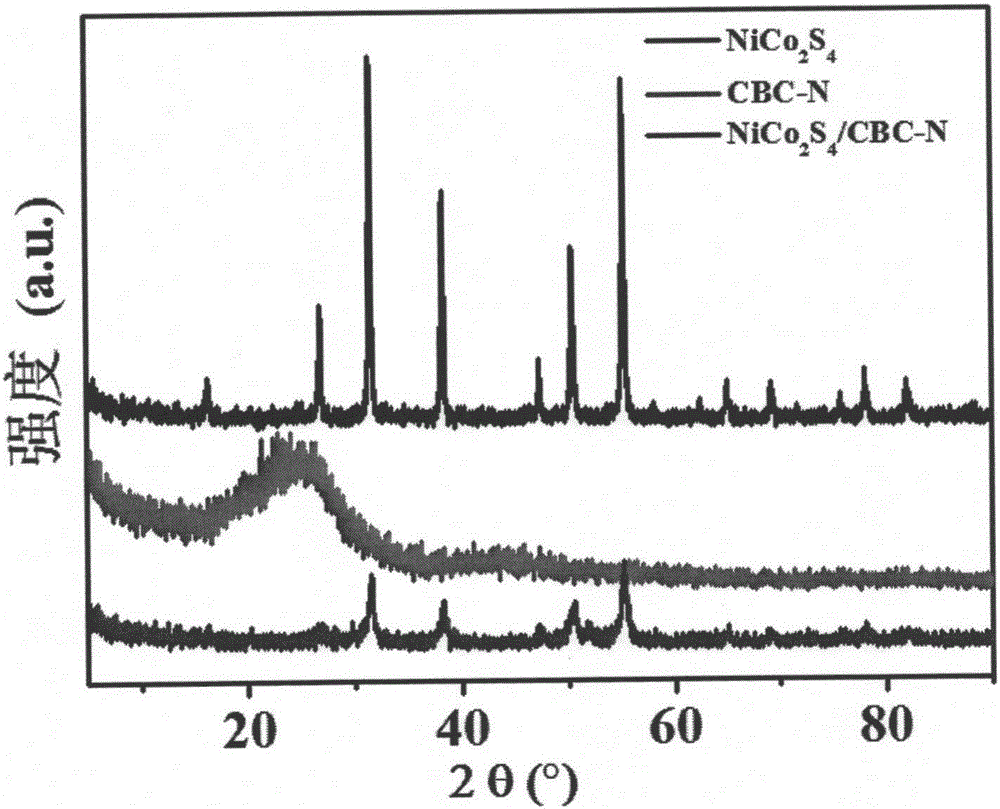

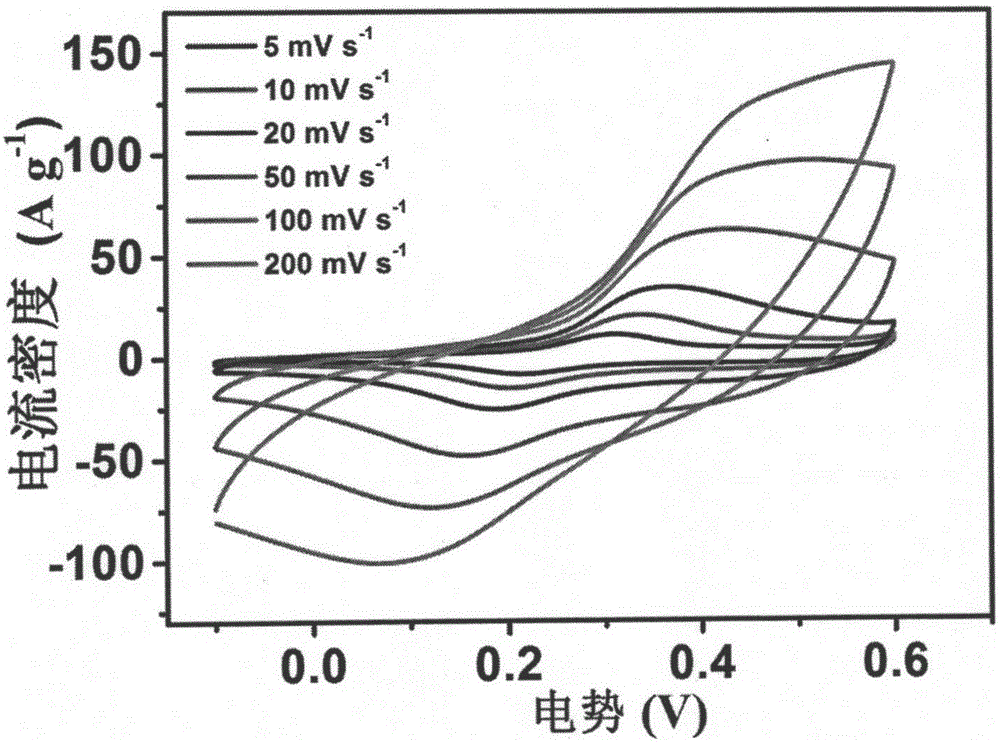

Cobalt-nickel sulfide/nitrogen-doped carbon nano-fiber composite material, preparation method and application thereof

A nitrogen-doped carbon, composite material technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of cycle performance degradation, volume expansion and shrinkage, etc., to achieve easy operation, good conductivity, effective The effect of the quick preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of a cobalt-nickel sulfide / nitrogen-doped carbon nanofiber composite material disclosed in this embodiment comprises the following steps:

[0045](1) Cut the bacterial cellulose membrane into 4×5cm 2 Size, take out 50 pieces 4×5cm 2 Bacterial cellulose of different sizes is dispersed in 500mL deionized water, and the preparation concentration is 1mol L -1 Potassium hydroxide solution, then added dropwise to the above dispersion until the solution is neutral;

[0046] (2) Take out the neutral bacterial cellulose, put it into liquid nitrogen for cooling, and place it in a freeze dryer for freeze-drying for 24 hours;

[0047] (3) Weigh 500mg of freeze-dried bacterial cellulose and disperse it in 400mL1molL -1 In the hydrochloric acid, add 0.67g pyrrole at the same time, soak for 12h;

[0048] (4) Take another 1.62g ferric chloride, dissolve it in 400mL 1mol L -1 in hydrochloric acid;

[0049] (5) adding the above-mentioned ferric chloride acidic ...

Embodiment 2

[0056] The difference between this embodiment and embodiment 1 is: change the concentration of cobalt nitrate in embodiment 1 to 3.33mmol L -1 The concentrations of nickel nitrate hexahydrate, thiourea and hexamethylenetetramine were reduced proportionally. All the other are the same as in Example 1.

Embodiment 3

[0058] The difference between this example and Example 1 is that the carbonization temperature in step (7) in Example 1 is changed to 800°C. All the other are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com