Process for preparing glucose and sodium chloride injection.

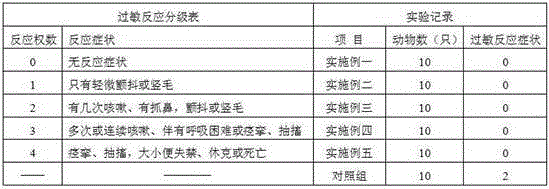

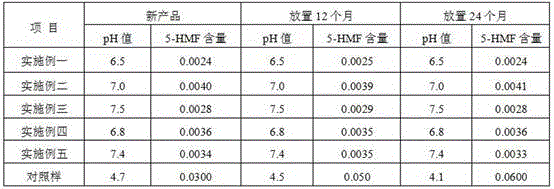

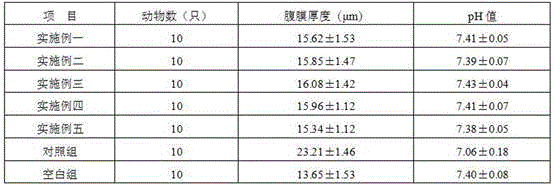

A glucose sodium chloride, production process technology, applied in the production process field of glucose sodium chloride injection, can solve the problems of long production cycle, slow dissolution rate, high content of glucose degradation product 5-HMF, etc., to achieve stable product quality, The effect of reducing the increase of content, ensuring biological safety and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of production technology of glucose sodium chloride injection of the present invention comprises the following steps:

[0034] 1) Weigh raw materials: Weigh the following raw materials in turn, glucose 60.00Kg, fructose 30.00Kg, xylitol 15.00Kg, magnesium chloride 0.510Kg, calcium chloride 0.370Kg, sodium chloride 1.460Kg, sodium acetate 0.820Kg, dihydrogen phosphate Potassium 1.740Kg, zinc sulfate 1.400g, sodium bisulfite 0.420Kg, citric acid 1.0Kg, water for injection 1000L;

[0035] 2) Raw material dissolution:

[0036] a) Add injection water at 30°C to a preparation tank with a volume of 300L, the amount of injection water is 10% of the total amount, start stirring, and add the above-mentioned sodium bisulfite, magnesium chloride, calcium chloride, sodium chloride and sulfuric acid in sequence Zinc, stirring and dissolving for 1min to make it all dissolve;

[0037] b) Add injection water at 50°C to the concentrated preparation tank with a volume of 600L, th...

Embodiment 2

[0044] A kind of production technology of glucose sodium chloride injection of the present invention comprises the following steps:

[0045] 1) Weigh raw materials: Weigh the following raw materials in turn, glucose 60.00Kg, fructose 30.00Kg, xylitol 15.00Kg, magnesium chloride 0.510Kg, calcium chloride 0.370Kg, sodium chloride 1.460Kg, sodium acetate 0.820Kg, dihydrogen phosphate Potassium 1.740Kg, zinc sulfate 1.400g, sodium bisulfite 0.420Kg, citric acid 1.1Kg, water for injection 1000L;

[0046] 2) Raw material dissolution:

[0047] a) Add injection water at 35°C to a preparation tank with a volume of 400L, the amount of injection water is 15% of the total amount, start stirring, and add sodium bisulfite, magnesium chloride, calcium chloride, sodium chloride and zinc sulfate in sequence , stir and dissolve for 3 minutes to make it all dissolve;

[0048] b) Add water for injection at 55°C to the concentrated preparation tank with a volume of 800L, the amount of water for ...

Embodiment 3

[0055] 1) Weigh raw materials: Weigh the following raw materials in turn, glucose 60.00Kg, fructose 30.00Kg, xylitol 15.00Kg, magnesium chloride 0.510Kg, calcium chloride 0.370Kg, sodium chloride 1.460Kg, sodium acetate 0.820Kg, dihydrogen phosphate Potassium 1.740Kg, zinc sulfate 1.400g, sodium bisulfite 0.420Kg, citric acid 1.2Kg, water for injection 1000L;

[0056] 2) Raw material dissolution:

[0057] a) Add injection water at 40°C to a preparation tank with a volume of 500L, the amount of injection water is 20% of the total amount, start stirring, and add sodium bisulfite, magnesium chloride, calcium chloride, sodium chloride and zinc sulfate in sequence , stir and dissolve for 5 minutes to make it all dissolve;

[0058] b) Add injection water at 60°C to the concentrated preparation tank with a volume of 1000L, the amount of injection water is 50% of the total amount, start stirring, add dipotassium hydrogen phosphate, after it dissolves, add glucose, fructose, wood Sug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com