Method for treating low-salt preserved Szechuan pickle processing wastewater by cultivating Spirulina

A technology of spirulina and mustard, applied in the field of processing low-salt wastewater from mustard processing, can solve the problems of increased pressure on environmental protection, pollution of farmland, river salt water, eutrophication of river water, etc., and achieve resource reuse and operation. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

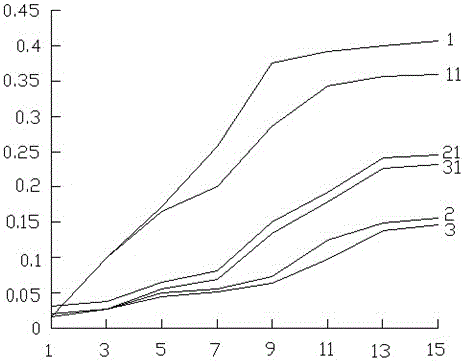

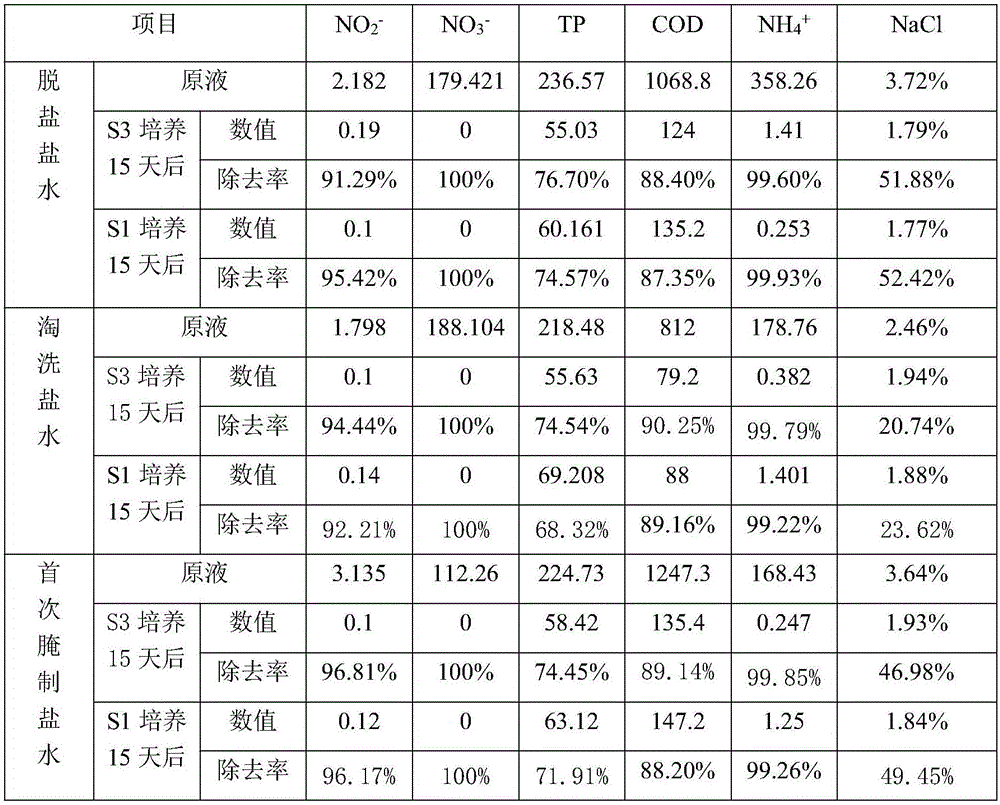

Embodiment 1

[0028] Precipitate the low-salt waste water from mustard processing for 12 hours, remove the precipitated sediment, and obtain a clarified liquid, boil the clarified liquid for 10 minutes, cool to normal temperature, and adjust the pH value to 11.5 with potassium hydroxide; mix potassium dihydrogen phosphate with sulfuric acid Magnesium is mixed in a mass ratio of 1:1 to obtain an ammonia-reducing mixture, which is added to the low-salt waste water of mustard mustard processing of the aforementioned gained, and the mass ratio of the ammonia-reducing mixture to the low-salt waste water of mustard mustard processing of the aforementioned gained is 6:100, stirring Evenly, filter with a layer of gauze after standing for 60 minutes, filter out the precipitated matter, and obtain the filtrate; add sodium bicarbonate in the filtrate, and the mass ratio of sodium bicarbonate and the filtrate is 0.45:100 to obtain pretreated Mustard processing low-salt wastewater solution; according to ...

Embodiment 2

[0030] Precipitate the low-salt waste water of mustard mustard processing for 6 hours, remove the precipitated sediment, and obtain a clear liquid, boil the clear liquid for 5 minutes, cool to normal temperature, and adjust the pH value to 9 with potassium hydroxide; mix potassium dihydrogen phosphate with sulfuric acid Magnesium is mixed in a mass ratio of 1:1.2 to obtain an ammonia-reducing mixture, which is added to the low-salt waste water of mustard mustard processing of the aforementioned gained, and the mass ratio of the ammonia-reducing mixture to the low-salt waste water of mustard mustard processing of the aforementioned gained is 1:100, stirring Evenly, filter with two layers of gauze after standing for 20 minutes, filter the precipitated matter, and obtain the filtrate; add sodium bicarbonate in the filtrate, the mass ratio of sodium bicarbonate and the filtrate is 0.3:100, and obtain the pretreated Mustard mustard processing low-salt wastewater solution; according ...

Embodiment 3

[0032] Precipitate the low-salt waste water of mustard mustard processing for 8 hours, remove the precipitated sediment, and obtain a clear liquid, boil the clear liquid for 7 minutes, cool to normal temperature, and adjust the pH value to 10 with potassium hydroxide; mix potassium dihydrogen phosphate with sulfuric acid Magnesium is mixed in a mass ratio of 1:1.1 to obtain an ammonia-reducing mixture, which is added to the low-salt waste water of mustard mustard processing of the aforementioned gained, and the mass ratio of the ammonia-reducing mixture to the low-salt waste water of mustard mustard processing of the aforementioned gained is 3:100, stirring Evenly, filter with three layers of gauze after standing for 30 minutes, filter out the precipitated matter, and obtain the filtrate; add sodium bicarbonate in the filtrate, and the mass ratio of sodium bicarbonate and the filtrate is 0.6:100 to obtain pretreated Mustard processing low-salt wastewater solution; according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com