Method and device for treating residual sludges

A technology for excess sludge and treatment equipment, which is applied in the direction of fertilization equipment, sewage/sludge fertilizer, biological organic part treatment, etc., can solve the problems of hindering earthworm respiration, high energy consumption, and easy to cause anaerobic environment, etc., to achieve easy Plant absorption and utilization, increasing the value of agricultural resources, improving the effect of growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

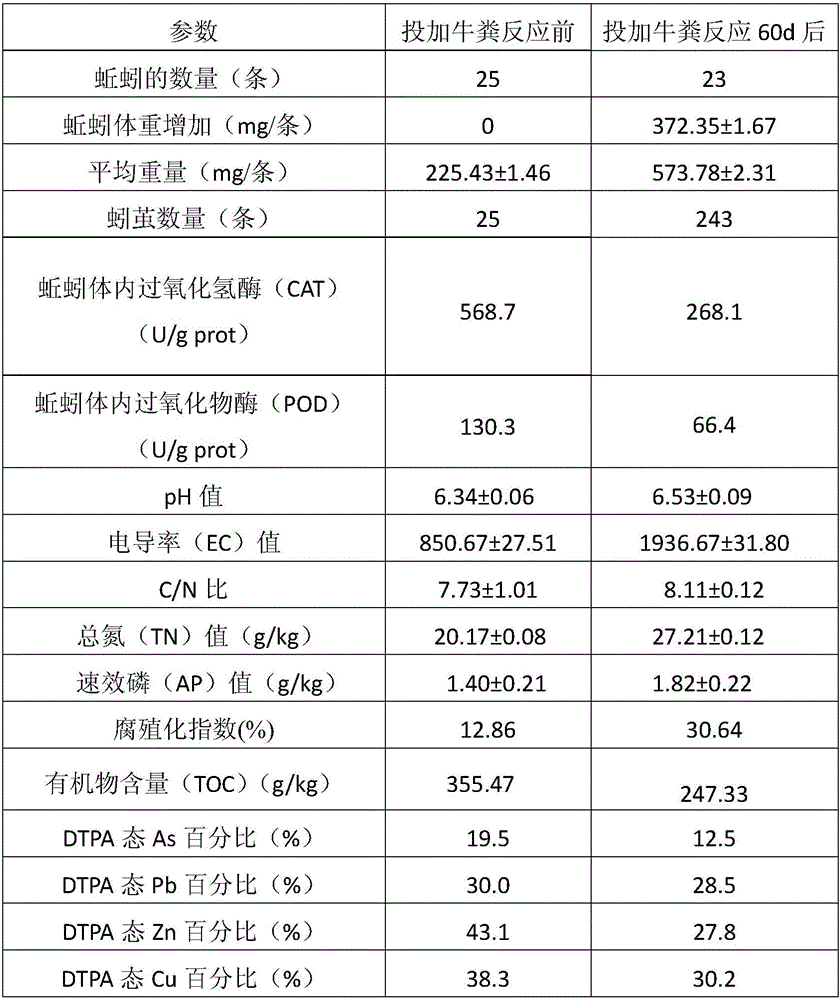

[0060] Embodiment 1: a kind of method for processing excess sludge

[0061] The method for processing surplus sludge in the present embodiment, it may further comprise the steps:

[0062](1), the conditioner cow dung (dry weight in this embodiment is 150g) and the remaining sludge with a moisture content of 80% (dry weight in this embodiment is 50g) are evenly mixed according to the dry weight ratio of 3:1, and cool Ventilate and place for 14 days, and turn it manually every 24 hours;

[0063] (2) After the remaining sludge and conditioner are mixed for 14 days, add 25 earthworms to each open container to form compost. The temperature of the compost is 23±2°C and the moisture content is 75±5%. After waiting for 60 days with the cover, the vermicompost sludge product is obtained.

[0064] Among them, the ventilated storage time is acceptable within 7-16 days, the frequency of manual turning is also acceptable within 12-36 hours, and the waiting time after adding earthworms is...

Embodiment 2

[0066] Embodiment 2: A kind of excess sludge treatment device

[0067] An excess sludge treatment device for implementing the above method for treating excess sludge includes: a cover and an open container arranged in sequence from top to bottom, the cover and the open container are detachably connected, and the cover is evenly distributed with through holes.

[0068] Wherein, open type container is the cylindrical container of polyethylene plastics, and its diameter is 10-20cm (can be preferably 15cm in the present embodiment), and height is 15-24cm (can be preferably 20cm in the present embodiment), lid through The density of holes is 1.67 / cm 2 , the aperture is 6-10 mesh (in this embodiment, it can be preferably 8 mesh).

[0069] The size or shape of the excess sludge treatment device in this embodiment is for illustration purposes only, and is not considered as a limitation to the actual size or actual shape of the product of the present invention. Those skilled in the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com