Soil conditioner for tea tree

A soil conditioner and tea tree technology, applied in the fields of application, organic fertilizer, inorganic fertilizer, etc., can solve the problems that affect the economic benefits of tea farmers, the ecological environment, affect the nutrient absorption and growth of tea trees, and reduce the availability of phosphorus, so as to improve water retention and fertilizer retention ability, improve the body's immunity, and promote the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The tea tree soil conditioner described in the present embodiment comprises the following components by weight: 3 parts of chitosan powder, 7 parts of yeast residue, 18 parts of sunflower meal, 25 parts of sepiolite powder, 3 parts of phosphate rock powder, natural 8 parts of potassium phosphate mineral powder, 4 parts of borax powder, 2 parts of calcium silicate powder, 4 parts of zinc mineral powder, 2 parts of ferrous sulfate, 2 parts of magnesium sulfate, 2 parts of manganese carbonate, 10 parts of seaweed fertilizer. The yeast residue is waste yeast residue in the yeast production process; the sunflower meal is crushed and passed through an 80-mesh sieve.

[0017] For example, the preparation method of the soil conditioner for tea trees is as follows: take the components in proportion by weight and mix them until they are evenly mixed.

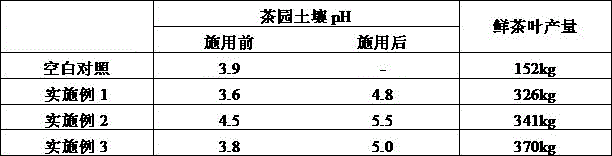

[0018] The soil conditioner for tea trees described in this implementation is used for the tea garden soil of pH3.6, and the appl...

Embodiment 2

[0020] The tea tree soil conditioner described in the present embodiment comprises the following components by weight: 4 parts of chitosan powder, 5 parts of yeast residue, 20 parts of sunflower meal, 25 parts of sepiolite powder, 4 parts of phosphate rock powder, natural 10 parts of potassium phosphate mineral powder, 4 parts of borax powder, 2 parts of calcium silicate powder, 3 parts of zinc mineral powder, 2 parts of ferrous sulfate, 1 part of magnesium sulfate, 1 part of manganese carbonate, 8 parts of seaweed fertilizer. The yeast residue is waste yeast residue in the yeast production process; the sunflower meal is crushed and passed through a 100-mesh sieve.

[0021] For example, the preparation method of the soil conditioner for tea trees is as follows: take the components in proportion by weight and mix them until they are evenly mixed.

[0022] Use the soil conditioner for tea trees described in this implementation for the tea garden soil of pH4.5, the application ra...

Embodiment 3

[0024] The tea tree soil conditioner described in the present embodiment comprises the following components by weight: 2 parts of chitosan powder, 8 parts of yeast residue, 15 parts of sunflower meal, 30 parts of sepiolite powder, 4 parts of phosphate rock powder, natural 6 parts of potassium phosphate mineral powder, 4 parts of borax powder, 1 part of calcium silicate powder, 3 parts of zinc mineral powder, 1 part of ferrous sulfate, 2 parts of magnesium sulfate, 2 parts of manganese carbonate, 12 parts of seaweed fertilizer. The yeast residue is waste yeast residue in the yeast production process; the sunflower meal is crushed and passed through a 60-mesh sieve.

[0025] For example, the preparation method of the soil conditioner for tea trees is as follows: take the components in proportion by weight and mix them until they are evenly mixed.

[0026] The soil conditioner for tea trees described in this implementation is used for the tea garden soil of pH3.8, and the applica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com