Outdoor ultrathin fireproof coating

A kind of fireproof coating, ultra-thin technology, applied in the direction of fireproof coating, anticorrosion coating, epoxy resin coating, etc., can solve the problem of poor anticorrosion, antirust, acid and alkali resistance, weather resistance, water resistance can not reach outdoor fireproof Coating, can not play a role in preventing hydrocarbon fires, etc., to achieve the effect of improving crosslinking density and curing rate, shortening curing time, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 15 parts of molybdenum trioxide, 20 parts of epoxy-terminated polyetheramine, 2 parts of polyoxyethylene polyoxypropanolamine ether, 8 parts of 1,12-dibromododecane, 7 parts of KH-560, graphite oxide 3 parts of alkene, 40 parts of tetraethyl orthosilicate and 15 parts of dimethyl sulfoxide were poured into the batching tank, stirred by a dispersing mixer, the stirring speed was controlled at 500 rpm, and the stirring time was 15 minutes to obtain component A ;

[0028] 8 parts of β-cyclodextrin modified amino-terminated sulfonated polybenzimidazole, 18 parts of quartz powder, 8 parts of KH-550, 3 parts of N,N-dimethylpiperazine, 8 parts of ethylene glycol and 9 parts of pentaerythritol Pour it into the batching tank, and stir it with a dispersing mixer. The stirring speed is controlled at 1000 rpm, and the stirring time is 30 minutes to obtain component B;

[0029] Mix the component A and component B in a weight ratio of 15:3 to obtain an outdoor ultra-thin fireproof c...

Embodiment 2

[0036] 15 parts of molybdenum trioxide, 20 parts of epoxy resin E51, 2 parts of polyoxyethylene polyoxypropanolamine ether, 8 parts of 1,12-dibromododecane, 7 parts of KH-560, and 3 parts of graphene oxide , 40 parts of ethyl orthosilicate and 15 parts of dimethyl sulfoxide were poured into the batching tank, stirred by a dispersing mixer, the stirring speed was controlled at 500 rpm, and the stirring time was 15 minutes to obtain component A;

[0037] 8 parts of β-cyclodextrin modified amino-terminated sulfonated polybenzimidazole, 18 parts of quartz powder, 8 parts of KH-550, 3 parts of N,N-dimethylpiperazine, 8 parts of ethylene glycol and 9 parts of pentaerythritol Pour it into the batching tank, and stir it with a dispersing mixer. The stirring speed is controlled at 1000 rpm, and the stirring time is 30 minutes to obtain component B;

[0038] Mix the component A and component B in a weight ratio of 15:3 to obtain an outdoor ultra-thin fireproof coating;

[0039] Wherein...

Embodiment 3

[0045] 15 parts of molybdenum trioxide, 20 parts of epoxy-terminated polyetheramine, 2 parts of polyoxyethylene polyoxypropanolamine ether, 8 parts of 1,12-dibromododecane, 7 parts of KH-560, graphite oxide 3 parts of alkene, 40 parts of tetraethyl orthosilicate and 15 parts of dimethyl sulfoxide were poured into the batching tank, stirred by a dispersing mixer, the stirring speed was controlled at 500 rpm, and the stirring time was 15 minutes to obtain component A ;

[0046] Pour 8 parts of amino-terminated sulfonated polybenzimidazole, 18 parts of quartz powder, 8 parts of KH-550, 3 parts of N,N-dimethylpiperazine, 8 parts of ethylene glycol and 9 parts of pentaerythritol into the batching tank, Stir with a dispersing mixer, the stirring speed is controlled at 1000 rpm, and the stirring time is 30 minutes to obtain component B;

[0047] Mix the component A and component B in a weight ratio of 15:3 to obtain an outdoor ultra-thin fireproof coating;

[0048] Wherein, the epo...

PUM

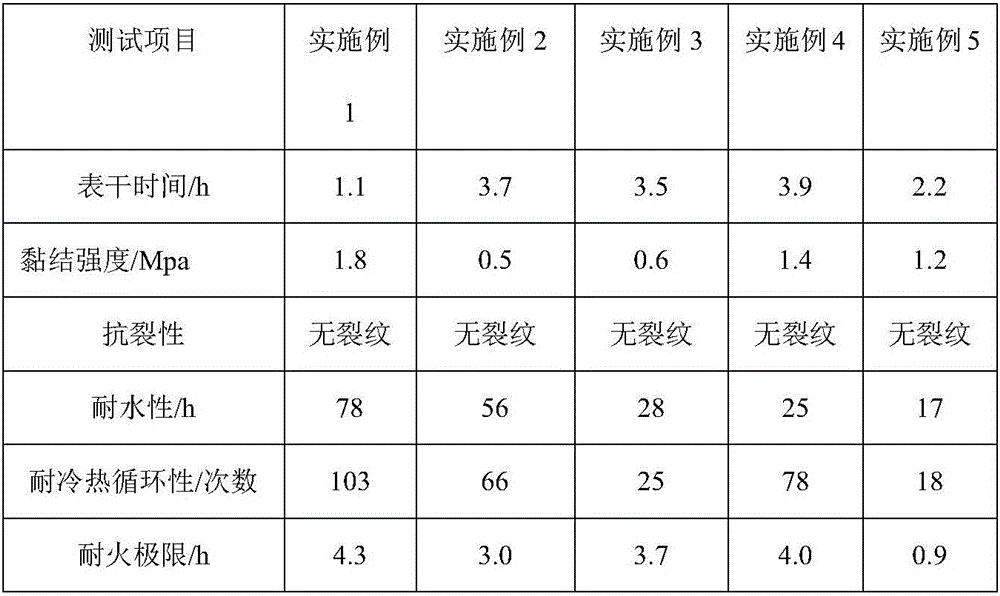

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com