High-precision circuit and preparation method thereof

A high-precision, circuit technology, applied in printed circuit manufacturing, printed circuits, chemical/electrolytic removal of conductive materials, etc., can solve problems such as large investment and difficulty in large-scale use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

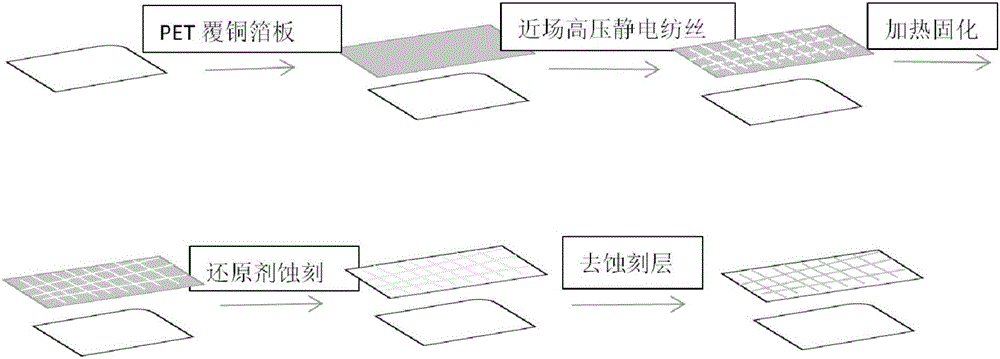

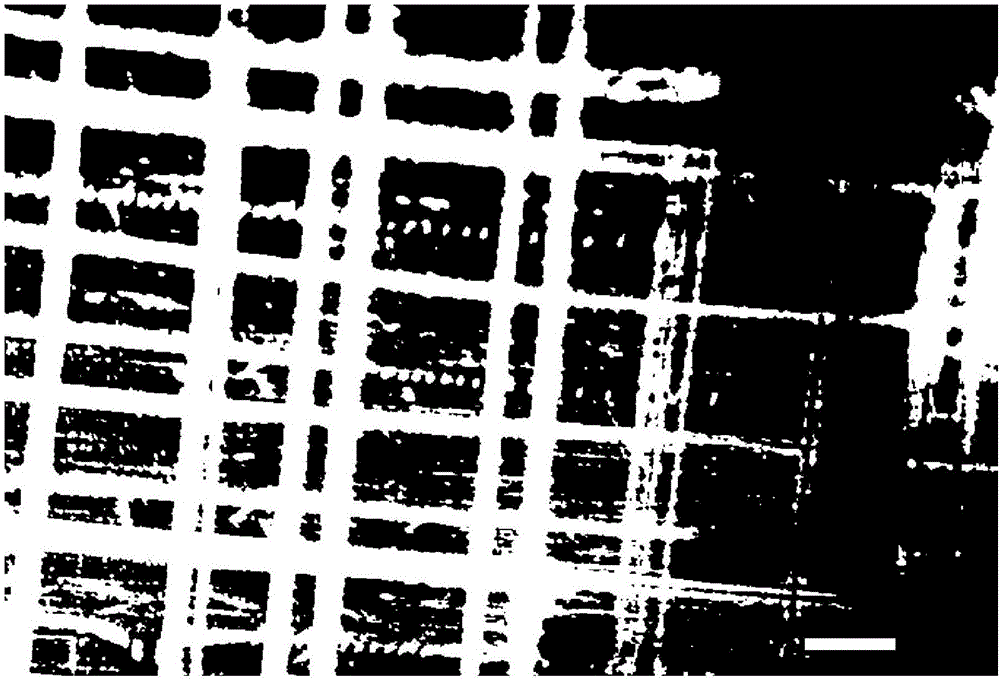

[0033]Prepare the dimethylformamide solution of polymethyl methacrylate resin for high-voltage electrospinning, and use the high-voltage electrospinning machine to spin the resin solution on the surface of a PET copper-clad foil board with a thickness of 1 μm. The technical parameters are that the nozzles are relatively The moving speed of the copper foil plate is 800mm / s; the hole diameter of the nozzle is 0.2mm; the temperature at the material bin, pipeline and nozzle is 50°C during operation. The working voltage is 2.75kv; the distance between the nozzle and the copper foil plate is 1mm; after near-field high-voltage electrospinning, an orderly narrow-linewidth anti-etching layer grid can be formed. After heating at 60°C for drying and curing, use an etchant containing copper chloride to restore the bare copper foil to an ionic state and dissolve it in the etching solution. Wash the copper foil surface twice with secondary water, and dry it with hot air at 40°C. Soak the c...

Embodiment 2

[0035] Prepare monomer vinyl acetate for high-voltage electrospinning, and use a high-voltage electrospinning machine to spin the monomer on the surface of silver foil with a thickness of 1 μm. The technical parameters are that the moving speed of the nozzle relative to the silver foil plate is 200mm / s; the aperture of the nozzle It is 0.08mm; the temperature of the material bin, pipeline and nozzle is normal temperature during operation. The working voltage is 2.5kv; the distance between the nozzle and the copper foil plate is 0.6mm; near-field high-voltage electrospinning can form a regular, orderly and controllable narrow line width structure, which is cured by ultraviolet light to form an anti-etching layer. Use an etchant containing potassium monopersulfate to reduce the bare silver foil to an ionic state and dissolve it in the etching solution. Clean the surface of the silver foil three times with secondary water, and dry it with hot air at 80°C. Soak the silver foil wi...

Embodiment 3

[0037] Prepare polyphenylene sulfide resin particles for high-voltage electrospinning, and prepare polyethylene terephthalate metal-clad aluminum foil plates; spray poly(ethylene terephthalate) on the surface of polyethylene terephthalate metal-clad aluminum foil plates through high-voltage electrospinning nozzles Phenylsulfide resin, high-voltage electrospinning technical parameters are: the moving speed of the nozzle relative to the metal foil-clad plate is 100mm / s; the aperture of the nozzle is 0.1mm; the temperature of the material bin, pipeline and nozzle is 180°C during operation. The working voltage is 5kv, and the distance between the nozzle and the metal clad plate is 0.5mm. The polyphenylene sulfide resin forms an anti-etching layer with a narrow line width on the surface of the metal aluminum foil; the metal aluminum foil not covered by the anti-etching layer is reduced with an etchant solution containing sodium persulfate, and dissolved in the solution. Then use se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com