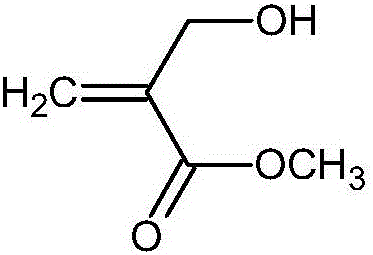

Preparation method of 2-hydroxymethyl methyl acrylate

A technology of methyl hydroxymethyl acrylate and methyl bromoacetate, which is applied in the field of preparation of 2-methyl hydroxy methacrylate, can solve the problems of large amount of "three wastes", low product purity, and many impurities, and achieve production costs Low, high product yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

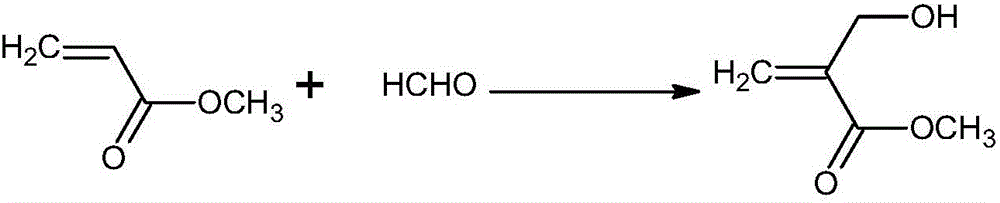

Method used

Image

Examples

Embodiment 1

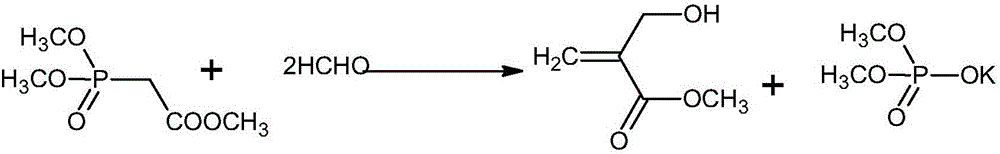

[0032] One, the preparation of methoxycarbonyl methylene triphenylphosphonium bromide:

[0033] Add 88g (0.29mol) triphenylphosphine to the three-necked flask, add 200ml toluene to dissolve, then dissolve 4.8g (0.029mol) KI in 200ml water and add toluene, add 44.4g (0.29mol) 2-bromoacetic acid dropwise methyl ester. Under the protection of nitrogen, the temperature was raised to 65-75°C and kept for 20 hours. After the heat preservation is over, cool down to 50-60°C, add 350ml of water, and separate the phases. The water phase was kept at 40°C, and 268.4 grams of 10% sodium hydroxide solution was slowly added dropwise. After the dropping, the solution was kept for 30 minutes, filtered with suction, the filter cake was rinsed with 40ml of n-heptane, and dried under reduced pressure at 50°C to obtain 119.2 grams of a yellow solid. Yield 90%.

[0034] Two, the preparation of 2-hydroxy methyl acrylate:

[0035] Add 119.2 grams of methoxycarbonylmethylene triphenylphosphine bro...

Embodiment 2

[0037] A preparation method of 2-methyl hydroxymethacrylate, comprising the following steps:

[0038] (1) Triphenylphosphine, catalyst and solvent are mixed, 2-methyl bromoacetate is added dropwise in the mixed solution, and the reaction is heated up;

[0039] (2) After the reaction finishes, leave it to stand for phase separation, and separate the toluene phase;

[0040] (3) drip aqueous sodium hydroxide solution, crystallization by cooling;

[0041] (4) suction filtration, rinse filter cake with n-heptane, make methoxycarbonyl methylene triphenyl phosphorus chloride, machine Wittig reagent;

[0042] (5) Add Wittig reagent to water, add formaldehyde aqueous solution, drop potassium carbonate aqueous solution to react;

[0043] (6) remove triphenylphosphine by filtration;

[0044] (7) filtrate is added to solvent extraction;

[0045] (8) Concentrate the organic phase, and distill under reduced pressure after removing the solvent to obtain 2-methyl hydroxymethacrylate.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com