Preparation method of sodium-ion battery anode material

A technology for sodium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low product crystallinity, low product tap density, and difficulty in mixing raw materials uniformly, and achieve excellent rate performance and cycle. performance, the effect of improving activity and crystallization ability, excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a sodium ion battery, in particular to a method for preparing hexagonal Na 2 / 3 Fe 1 / 2 mn 1 / 2 o 2 Methods. include:

[0037] Mix the sodium source, iron source and manganese source evenly to obtain a mixture;

[0038] mixing the mixture with an oxidizing agent, performing an oxidation reaction by ultrasonic vibration, to obtain a reactant;

[0039] drying and activating the reactants to obtain a precursor;

[0040] calcining the precursor in the air, and rapidly cooling to obtain the positive electrode material;

[0041]Wherein the positive electrode material is a hexagonal sodium ion compound Na 2 / 3 Fe 1 / 2 mn 1 / 2 o 2 .

[0042] According to the present invention, the chemical formula of the sodium ion compound preferably prepared is Na 2 / 3 Fe 1 / 2 mn 1 / 2 o 2 . In order to obtain a product with high crystallinity and uniform structure, the present invention preferably uses iron source and manganese source as ...

Embodiment 1

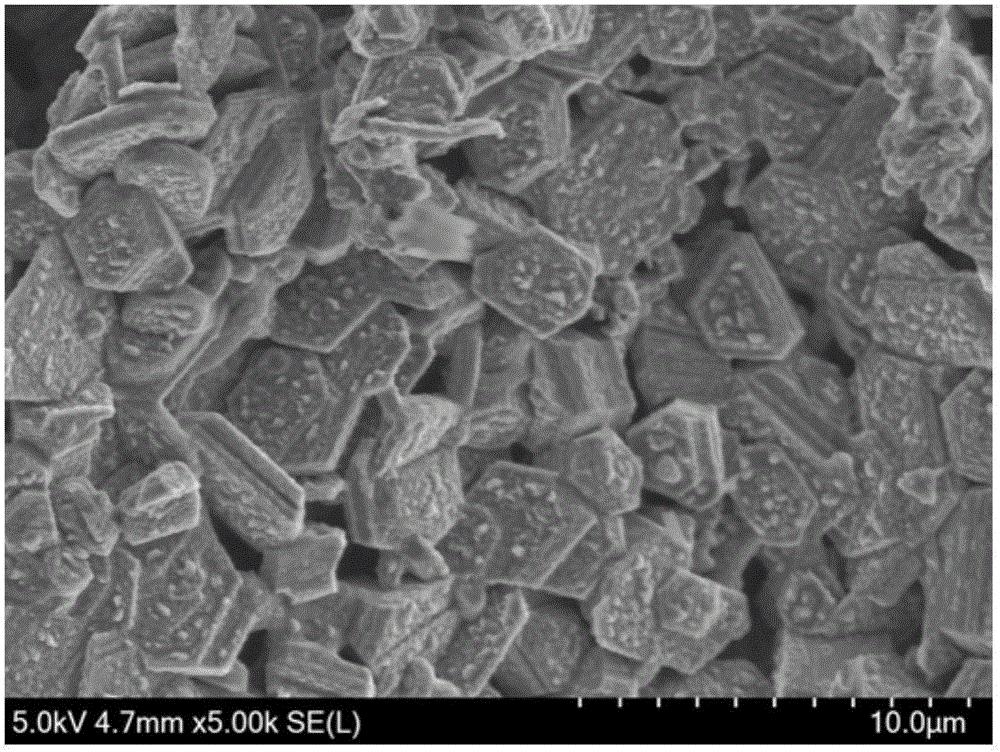

[0049] Take by weighing sodium ethylate, ferrous oxalate and manganese acetate by molar ratio Na:Fe:Mn=4.05:3:3, mix, then add the hydrogen peroxide that concentration is 20% (by molar ratio hydrogen peroxide: (Fe+ Mn)=3:1), ultrasonically oscillated for 90 minutes (oscillation frequency is 80kHz), the resulting mixture was dried at 80°C, and then mechanically activated for 4 hours (rotational speed was 300r / min) to obtain the precursor powder, the precursor was in Calcined in air at 800°C for 8 hours, and immediately placed the calcined powder in liquid nitrogen for rapid cooling to obtain hexagonal Na 2 / 3 Fe 1 / 2 mn 1 / 2 o 2 . Such as figure 1 Shown, for preparing Na in embodiment 1 2 / 3 Fe 1 / 2 mn 1 / 2 o 2 The scanning electron microscope picture shows that the structure of the hexagonal crystal is uniform and the crystallinity is high.

Embodiment 2

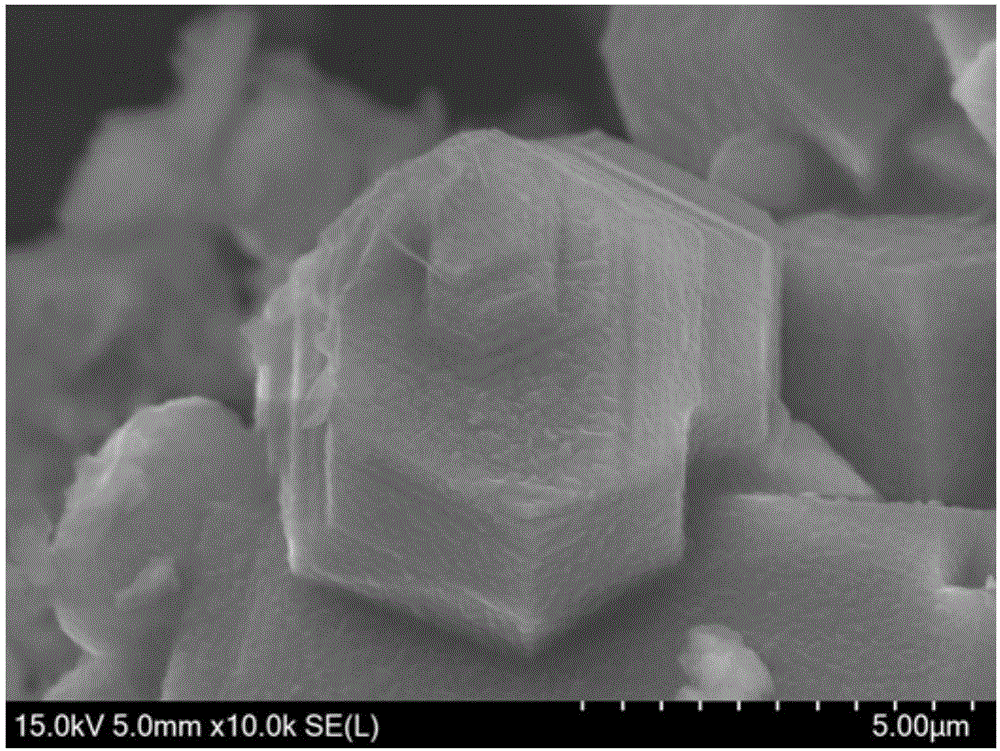

[0051] Take by weighing sodium hydroxide, ferric citrate and manganese glycinate by molar ratio Na:Fe:Mn=4:3:3.05, mix, then add the hydrogen peroxide that concentration is 5% (by molar ratio hydrogen peroxide: (Fe +Mn)=10:1), ultrasonically oscillate for 160 minutes (oscillation frequency is 20kHz), the resulting mixture is dried at 70°C, and then mechanically activated for 12 hours (rotating speed is 200r / min) to obtain the precursor powder, the precursor The body was calcined in the air at 900°C for 1 hour, and the calcined powder was immediately cooled in the air to obtain hexagonal Na 2 / 3 Fe 1 / 2 mn 1 / 2 o 2 . Such as figure 2 Shown, for preparing Na in embodiment 2 2 / 3 Fe 1 / 2 mn 1 / 2 o 2 The scanning electron microscope picture shows that the structure of the hexagonal crystal is uniform and the crystallinity is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com