Graphene oxide modified bone cement and preparation method

A technology of graphene modification and bone cement, which is applied in the fields of medical formula, medical science, tissue regeneration, etc., can solve the problems of slow formation of degradation rate, low mechanical strength, slow degradation rate, etc., and achieve good biocompatibility and reliability Degradability, improvement of mechanical properties, effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

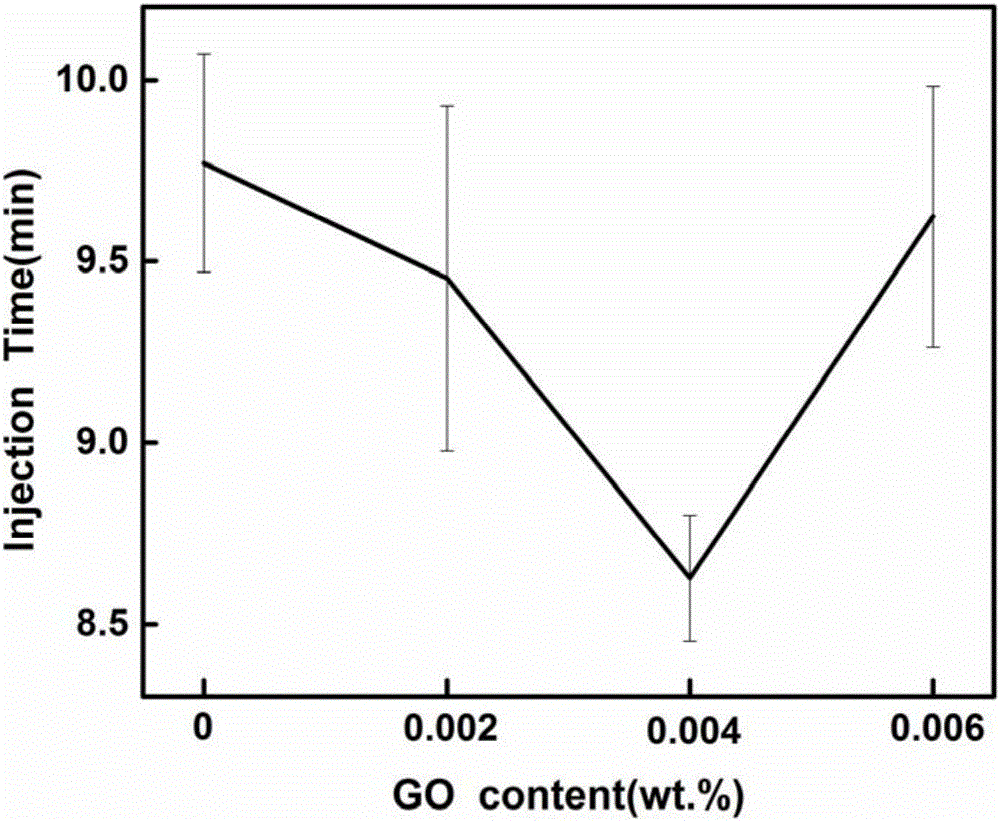

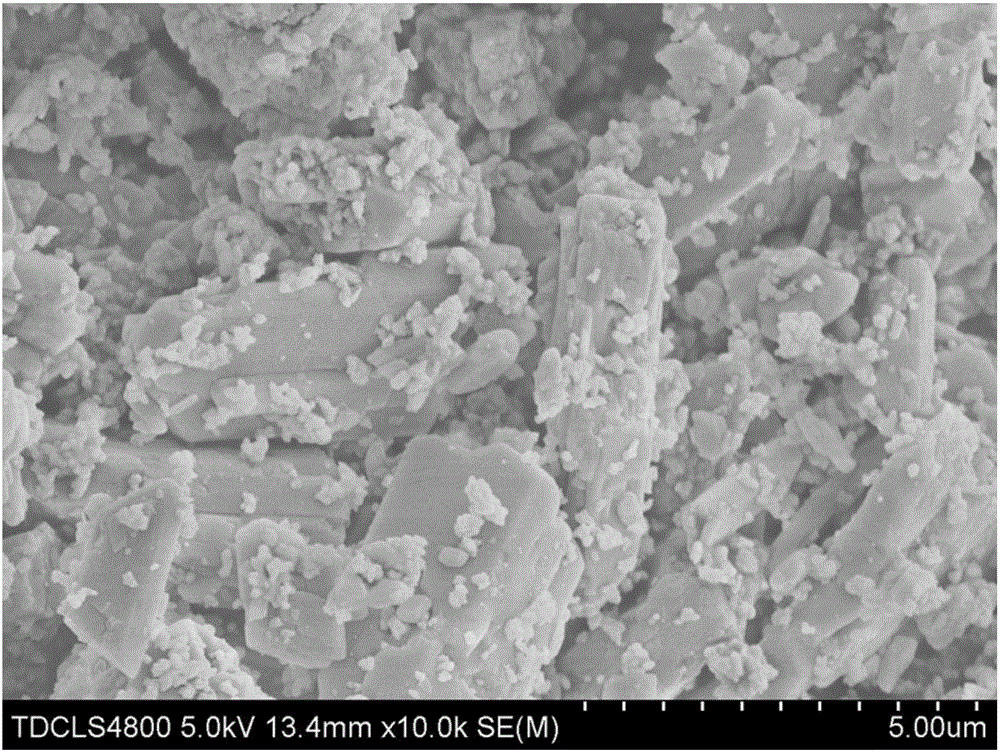

[0022] Bone cement composite powder includes α-calcium sulfate hemihydrate, strontium-doped hydroxyapatite powder. At room temperature, weigh 4g (80%) of calcium sulfate hemihydrate and 1g (20%) of strontium-doped hydroxyapatite, and mix them uniformly; The powder (liquid-solid ratio is 0.5mL / g) is mixed and stirred for 2 minutes, and the injectable time is about 9.4 minutes. figure 1 shown. The cured bone cement was ground into powder for SEM characterization, as shown in the attached figure 2 As shown, the cured bone cement is distributed in a columnar shape, and hydroxyapatite is distributed on it. The attachment of hydroxyapatite does not affect the basic morphology of the bone cement, and can also improve the biological activity of the bone cement.

Embodiment 2

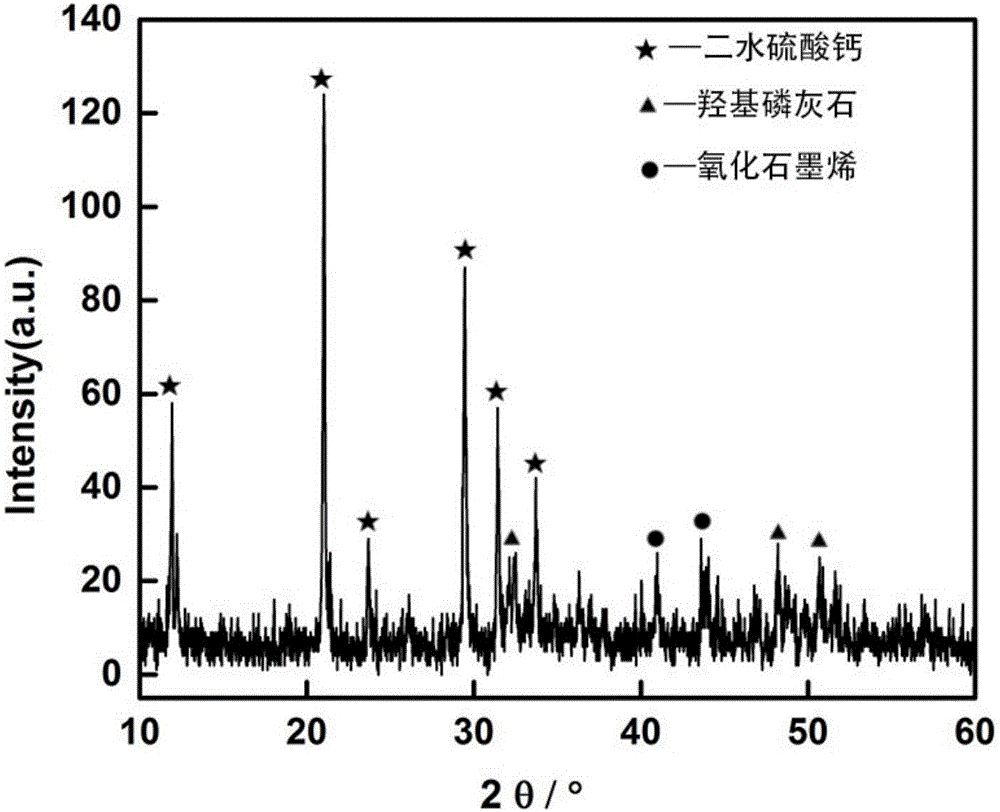

[0024] Preparation of bone cement composite powder: at room temperature, weigh 4g (80%) calcium sulfate hemihydrate and 1g (20%) strontium-doped hydroxyapatite, mix well; weigh 2.5mL with a mass fraction of 0.004% The graphene oxide aqueous solution was mixed with the solid phase powder (liquid-solid ratio: 0.5mL / g) and stirred for 2 minutes, and the injectable time was about 8.6 minutes. Carry out scanning electron microscope observation to curing product according to embodiment 1, and carry out phase analysis (namely XRD characterization) to the sample after curing, as attached image 3 As shown, the cured bone cement components are calcium sulfate dihydrate, hydroxyapatite and carbon, and the main component is calcium sulfate dihydrate, which shows that calcium sulfate hemihydrate quickly turns into calcium sulfate dihydrate during the curing process. Studies have shown that calcium sulfate dihydrate can promote the attachment of osteoblasts and promote osteogenesis, while ...

Embodiment 3

[0026] At room temperature, weigh 4g (80%) of calcium sulfate hemihydrate and 1g (20%) of strontium-doped hydroxyapatite, and mix them uniformly; The powder (liquid-solid ratio is 0.5mL / g) was mixed and stirred for 2 minutes, and the injectable time was about 9.6 minutes. Carry out phase analysis and scanning electron microscope observation to solidified product according to embodiment 2, and carry out compressive strength test to bone cement sample, compressive strength test sample is cylindrical (Φ 6mm * 12mm), and compressive strength average value is 6.42Mpa, in line with the requirements of human cancellous bone compressive strength (5 ~ 10Mpa), as attached Figure 4 It shows that the addition of graphene oxide can indeed improve the compressive strength of bone cement. After curing, the bone cement was soaked in SBF solution, and the collapse resistance was good. Embodiment 4:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com